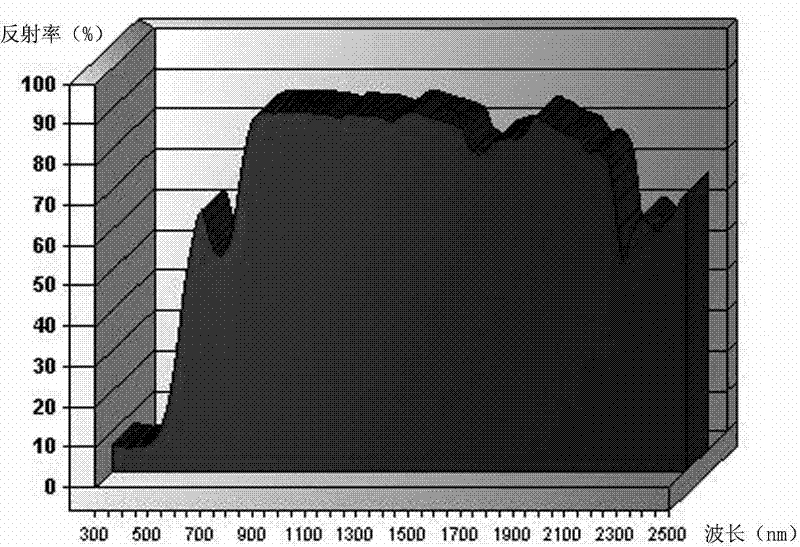

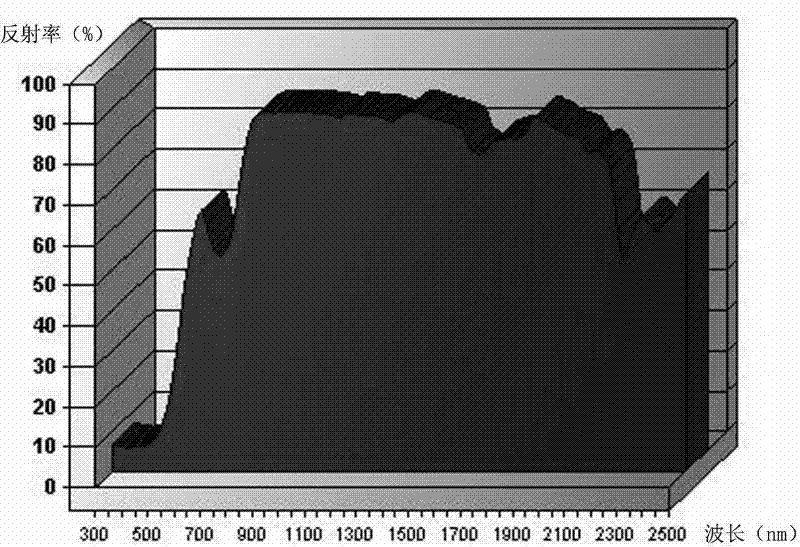

Polyolefin color masterbatch having infrared reflection effect and preparation method thereof

An infrared and polyolefin technology, applied in the field of polyolefin color masterbatch, can solve the problems of no reflection of infrared light and stuffy heat in pigments, achieve good social and economic benefits, reduce surface temperature, and improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Under normal temperature and pressure, the following components and mass percentages: polyethylene 2102 resin: 50kg, rutile R902 titanium dioxide 6kg, zinc stearate 2kg, polyethylene wax 7kg, CI blue 28 pigment 20kg, pigment yellow 150 pigment 8kg , Ultraviolet absorber UV-326 4 kg, light stabilizer 788 2 kg, antioxidant B225 1 kg. The components are mixed in proportion, and then mixed in a high-speed mixer with a rotating speed of 800~1500r / min for 10~20min, using a twin-screw extruder, the screw speed is 100~300r / min, and the temperature is controlled at 160~180℃ , Carry out extrusion granulation, and prepare the masterbatch of the present invention after cooling and drying.

Embodiment 2

[0020] Under normal temperature and pressure, the following components and mass percentages: 60 kg of polyethylene 2102 resin, 5 kg of rutile titanium dioxide, 5 kg of polyethylene wax, 2 kg of zinc stearate, 4 kg of ultraviolet absorber UV-326, light stable Agent 788 2kg, antioxidant B225 1kg, CI blue 36 pigment 12 kg, CI brown 24 pigment 9kg. The components are mixed in proportion, and then mixed in a high-speed mixer with a speed of 800~1500r / min for 10~20min, using a twin-screw extruder, the screw speed is 100~300r / min, and the temperature is controlled at 160~180℃ , Carry out extrusion granulation, and prepare the masterbatch of the present invention after cooling and drying.

Embodiment 3

[0022] Under normal temperature and pressure, the following components and mass percentages: 68kg of polyethylene 2102 resin, 2 kg of R902 titanium dioxide, 2kg of polyethylene wax, 2kg of zinc stearate, 10 kg of CI green 50 pigment, and 9 kg of CI yellow 216 pigment , Ultraviolet absorber UV-326 4 kg, light stabilizer 770 2kg, antioxidant B225 1kg. The components are mixed in proportion, and then mixed in a high-speed mixer with a speed of 800~1500r / min for 10~20min, using a twin-screw extruder, the screw speed is 100~300r / min, and the temperature is controlled at 160~180℃ , Carry out extrusion granulation, and prepare the masterbatch of the present invention after cooling and drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com