Near-infrared camouflage master batch and preparation method thereof, near-infrared camouflage fiber and fabric

A near-infrared and fiber technology, applied in the fields of fiber chemical characteristics, rayon manufacturing, textiles and papermaking, etc., can solve the problems of complicated steps and great influence on dyeing effect, and achieve good camouflage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a preparation method of the near-infrared camouflage masterbatch described in the above scheme, which includes the following steps: mixing functional powder with chemical fiber and performing melt extrusion to obtain the near-infrared camouflage masterbatch.

[0034] In the present invention, the chemical fibers are preferably chemical fiber chips, specifically polyester chips or nylon chips; the melting temperature of the screw extrusion is preferably 280°C, and the melt extrusion is preferably twin-screw extrusion; During the extrusion process, the chemical fiber slices are melted and fully mixed with the functional powder, and the near-infrared camouflage masterbatch is obtained after extrusion.

[0035] In a specific embodiment of the present invention, it is preferable to carry out screw extrusion of each functional powder separately with chemical fiber slices to obtain a variety of near-infrared camouflage masterbatches. Accordin...

Embodiment 1

[0050] Aluminum powder with a particle size of 1 μm is mixed with polyester chips for twin-screw extrusion at a melting temperature of 280°C to produce aluminum powder polyester masterbatches with a mass fraction of aluminum powder of 20%;

[0051] Mix zinc oxide with a particle size of 500nm and polyester chips for twin-screw extrusion at a melting temperature of 280°C to produce a zinc oxide polyester masterbatch with a mass fraction of zinc oxide of 40%;

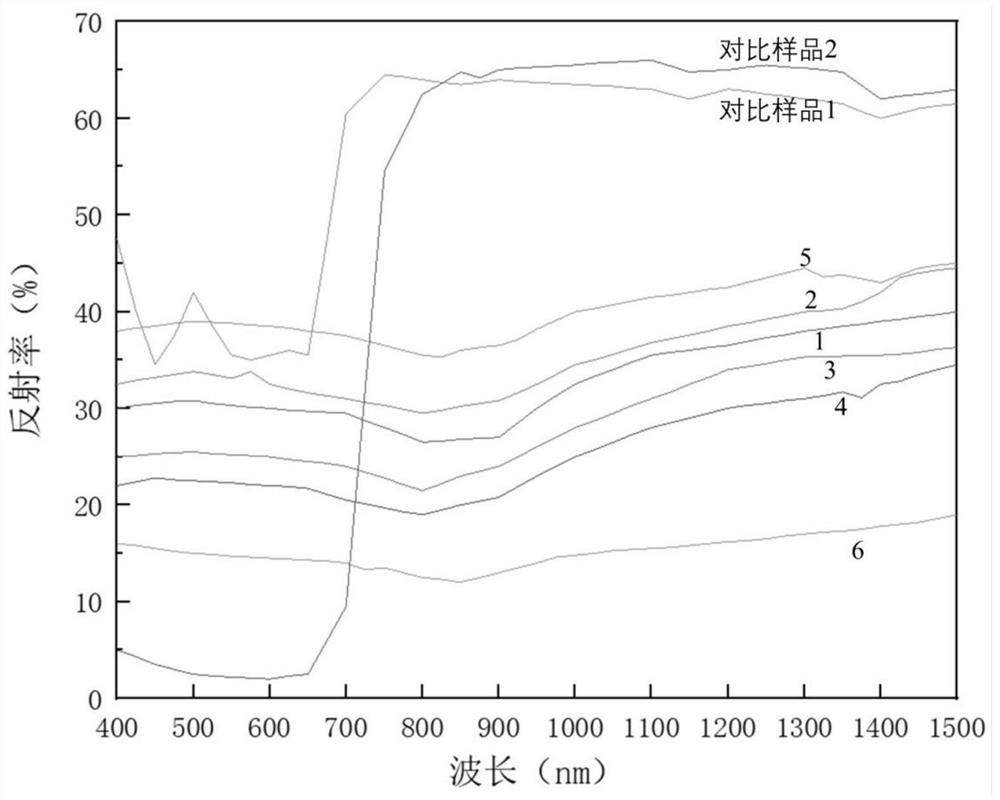

[0052] Take 200g of aluminum powder polyester masterbatch, 400g of zinc oxide polyester masterbatch, mix with 9.4kg of polyester masterbatch, and spin to obtain No. 1 fiber.

[0053] Take 400g of aluminum powder polyester masterbatch and 300g of zinc oxide polyester masterbatch, mix them with 9.3kg of polyester masterbatch, and spin to obtain No. 2 fiber.

[0054] Take 600g of aluminum powder polyester masterbatch and 200g of zinc oxide polyester masterbatch, mix them with 9.2kg of polyester masterbatch, and spin to obtai...

Embodiment 2

[0065] The rare earth-containing oxide with a particle size of 1-3 μm is mixed with polyester chips for twin-screw extrusion, and the melting temperature is 280 ° C to produce a rare earth-based polyester masterbatch with a mass fraction of rare earth oxides containing 10%;

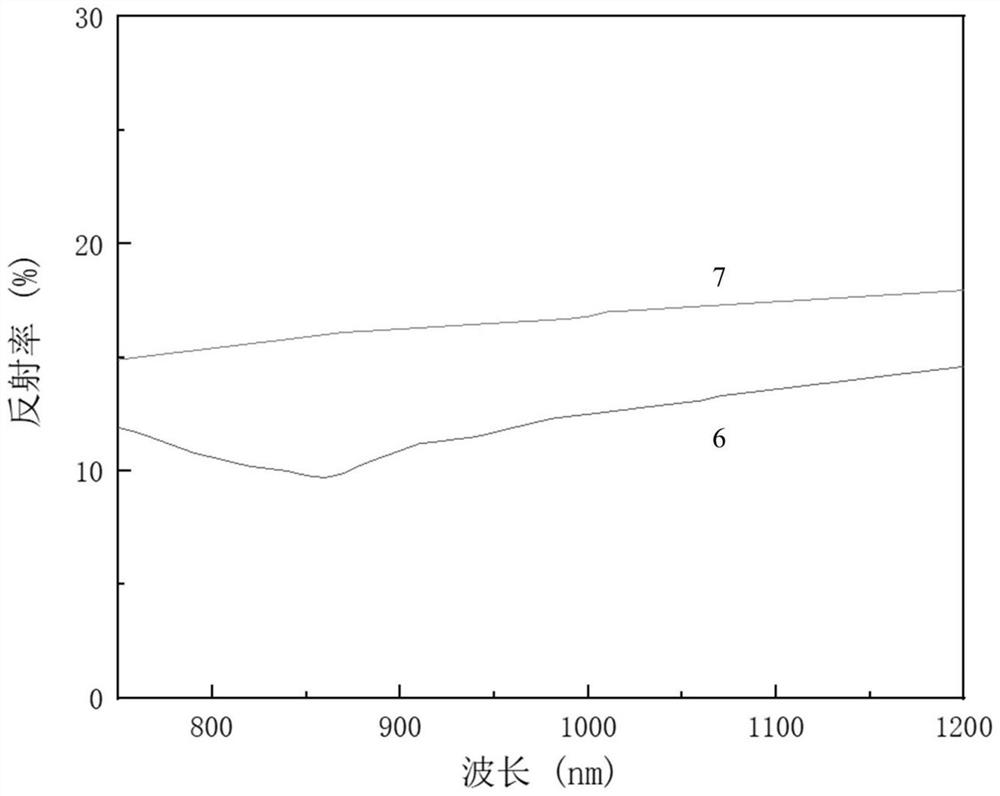

[0066] 1 kg of rare earth-based polyester masterbatch, 9 kg of polyester masterbatch, mixed and spun to obtain No. 6 fiber, the spinning temperature is 280 ° C, the fiber specification is 15D, and the mass fraction of rare earth oxide in No. 6 fiber is 1%.

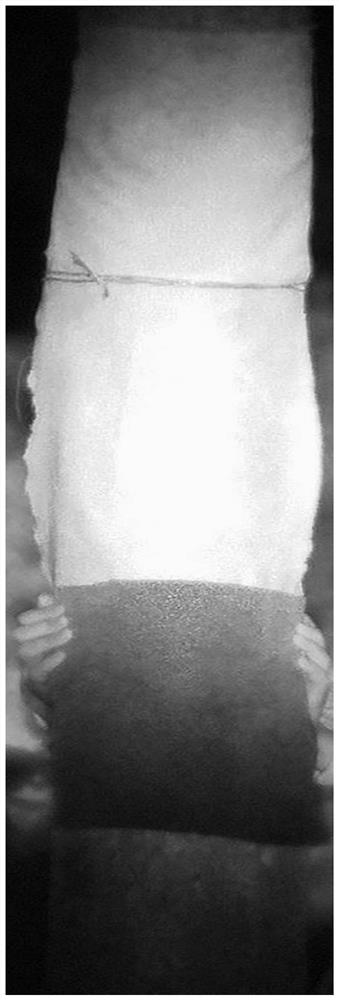

[0067] The No. 6 fiber was warp-weft-woven to obtain the No. 6 fabric. The near-infrared reflectance of the No. 6 fabric was tested, and the results showed that the near-infrared reflectance of the No. 6 fabric at 750-1200nm was 9-15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com