Exterior wall coating with solar heat reflecting function and preparation method of exterior wall coating

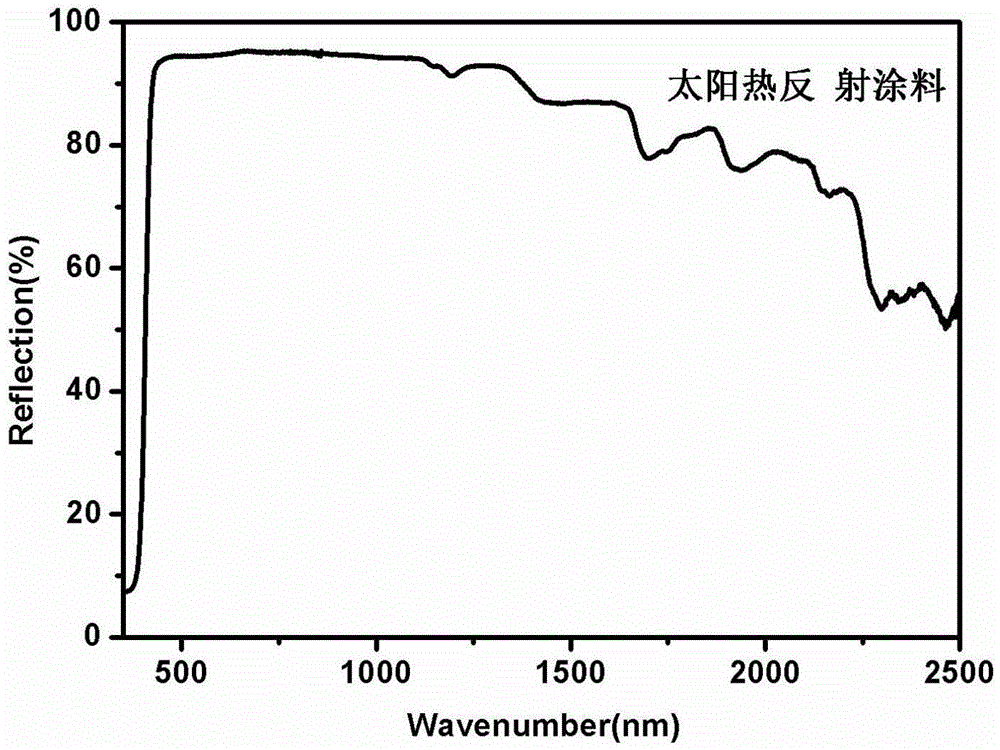

A technology of exterior wall paint and solar heat, applied in the field of paint, can solve problems such as easy breakage, reduce paint reflectivity, affect heat insulation performance, etc., achieve high total solar energy reflectivity, avoid rough paint film, and avoid white tone. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

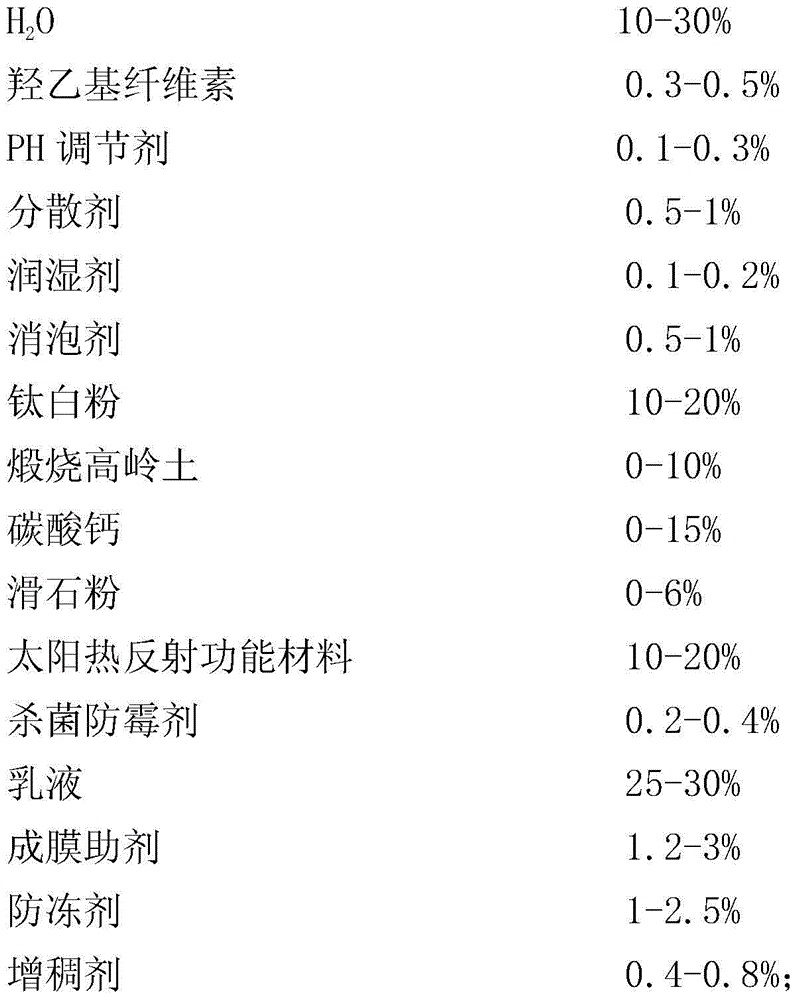

[0028] A kind of exterior wall paint with solar heat reflection function, which is prepared from the following components according to the following mass fraction ratio:

[0029]

[0030] The solar heat reflective functional material is TiO 2 SiO 2 Core-shell particle powder; the emulsion is one of pure acrylic emulsion, silicon acrylic emulsion or vinegar acrylic emulsion.

[0031] The TiO 2 SiO 2 The core-shell particle powder is prepared as follows:

[0032] (A) TiO with a particle size ranging from 1.1 to 1.4 μm 2 Preparation of granules:

[0033] Dissolve tetraalkyl titanate in small molecule alcohols with a C number of 1 to 4 to form a 5 to 8 wt.% solution A; prepare 0.1M Lutensol ON50 surfactant aqueous solution B; take solution B and dissolve it in C Among the small molecule alcohols with a number of 1-4, configure 0.5-1.0wt.% solution C; mix solution A and solution C, and the mixing mass ratio is 1:2-1:4; then heat the mixed solution React at 50-90°C for 2-4...

Embodiment 1

[0043] Embodiment 1: A kind of exterior wall paint with solar heat reflection function, it is formulated by following components by following mass fraction ratio:

[0044]

[0045] The solar heat reflective functional material is the TiO prepared above 2 SiO 2 Core-shell particle powder.

[0046] The preparation method of the exterior wall paint with solar heat reflection function described in this embodiment is prepared according to the following method:

[0047] (1) At a speed less than 500r / min, sequentially add water, hydroxyethyl cellulose, and pH regulator to disperse for 1 min;

[0048] (2) Increase the speed to 800r / min, first add wetting agent, dispersant, defoamer, bactericide and antifungal agent in turn, then add titanium dioxide, calcined kaolin, calcium carbonate, solar heat reflective functional materials, and then increase the speed to 1800r / min, disperse for 20min;

[0049] (3) Reduce the rotational speed to 1000r / min, add emulsion, film-forming aid, an...

Embodiment 2

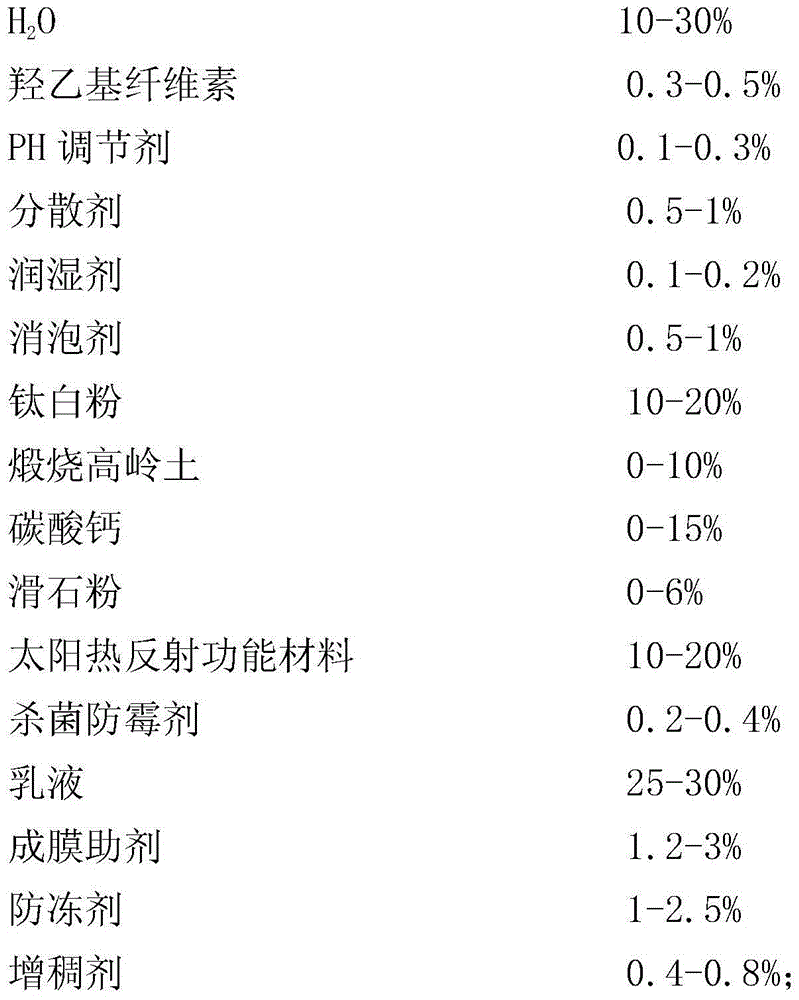

[0050] Embodiment 2: a kind of exterior wall paint with solar heat reflection function, it is formulated by following components by following mass fraction ratio:

[0051]

[0052] The solar heat reflective functional material is TiO 2 SiO 2 Core-shell particle powder.

[0053] The preparation method of the exterior wall paint with solar heat reflection function described in this embodiment is prepared according to the following method:

[0054] (1) At a speed less than 500r / min, sequentially add water, hydroxyethyl cellulose, and pH regulator to disperse for 2 minutes;

[0055] (2) Increase the speed to 900r / min, first add wetting agent, dispersant, defoamer, bactericide and antifungal agent in turn, then add titanium dioxide, calcium carbonate, talcum powder, solar heat reflective functional materials, and then increase the speed to 1900r / min, disperse for 18min;

[0056] (3) Reduce the rotation speed to 1100r / min, add emulsion, film-forming aid, antifreeze, thickener...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com