Method for synthesizing aluminium oxide powder by using combustion method

A technology of alumina powder and combustion method, which is applied in chemical instruments and methods, alumina/hydroxide preparation, inorganic chemistry, etc., can solve the problems of high production cost, large amount of waste liquid, high cost, etc., and achieve the synthesis process flow Short, fast response, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Prepare spherical alumina powder according to the following steps:

[0052] (1) Oxygen delivery: deliver oxygen into the reaction device, oxygen flow rate: 2.5m 3 / h;

[0053] (2) Aluminum powder transportation: Aluminum powder with a purity of more than 99% and a particle size of ≤100 μm is transported from the storage tank into the reaction device through argon gas; the amount of aluminum powder added is 2Kg / h, and the flow rate of argon gas is 0.8m 3 / h;

[0054] (3) Ignition: use high-voltage pulse ignition, frequency 10 times / 1s;

[0055] (4) Combustion: After the aluminum powder is ignited, it continues to burn stably in the form of flash combustion in oxygen; the cooling water flow rate of the reaction device is 900L / h;

[0056] (5) Cooling: The combustion product is cooled with nitrogen in time to form alumina powder, and the flow rate of nitrogen is 5m 3 / h.

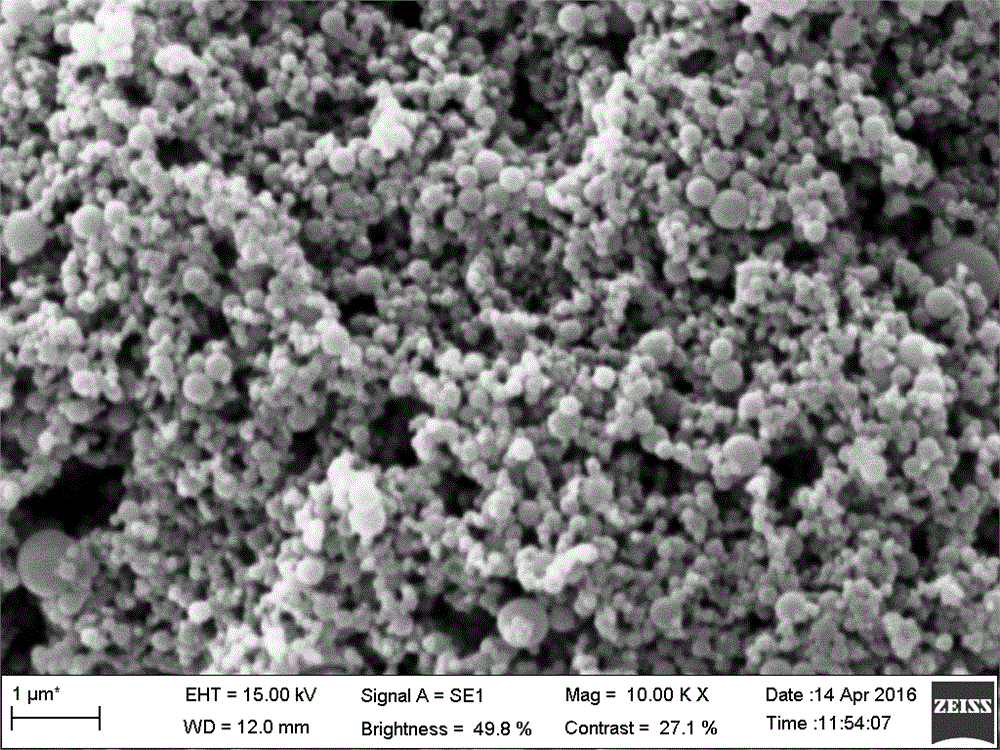

[0057] After recovering the product, spherical alumina powder with two sizes of D50-400nm and D50...

Embodiment 2

[0059] Prepare spherical high-purity alumina powder according to the following steps:

[0060] (1) Oxygen delivery: deliver oxygen into the reaction device, oxygen flow rate: 3.5m 3 / h;

[0061] (2) Aluminum powder transportation: Aluminum powder with a purity of more than 99.99% and a particle size of 100 μm is transported into the reaction device through argon gas; the amount of aluminum powder added is 3Kg / h, and the flow rate of argon gas is 1m 3 / h;

[0062] (3) Ignition: In the reaction device, use an arc to ignite between the oxygen input port and the aluminum powder input port in the reaction device, with a frequency of 15 times / 1s;

[0063] (4) Combustion: After the aluminum powder is ignited, it burns continuously and stably in the form of boiling combustion in oxygen, and the cooling water flow rate of the reaction device is 1000L / h;

[0064] (5) Cooling: The combustion product is cooled with argon gas in time to form alumina powder, and the flow rate of argon ga...

example 3

[0068] Prepare spherical high-purity alumina powder according to the following steps:

[0069] (1) Oxygen delivery: transport oxygen into the reaction device, oxygen flow rate: 9m 3 / h;

[0070] (2) Aluminum powder transportation: Aluminum powder with a purity of more than 99.99% and a particle size of 50 μm is transported into the reaction device through argon gas; the amount of aluminum powder added is 5Kg / h, and the flow rate of argon gas is 1m 3 / h;

[0071] (3) Ignition: Ignite with a hydrogen-oxygen flame in the reaction device, the frequency is 20 times / 1s;

[0072] (4) Combustion: After the aluminum powder is ignited, it burns continuously and stably in the form of suspended combustion in oxygen, and the cooling water flow rate of the reaction device is 1000L / h;

[0073] (5) Cooling: The combustion product is cooled with helium in time to form alumina powder, and the flow rate of helium is 6.5m 3 / h.

[0074] After the combustion reaction starts, it begins to coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com