Environment-friendly superfine tin wire and preparation method thereof

A kind of solder wire, environment-friendly technology, applied in the field of environment-friendly ultra-fine solder wire and its preparation, can solve problems such as components, circuit short circuit, easy bridging, etc., achieve improved lubricity, short production cycle, prevent oxidation and tin The effect of metamorphic elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0038] The preparation method of embodiment 1~6 is as follows:

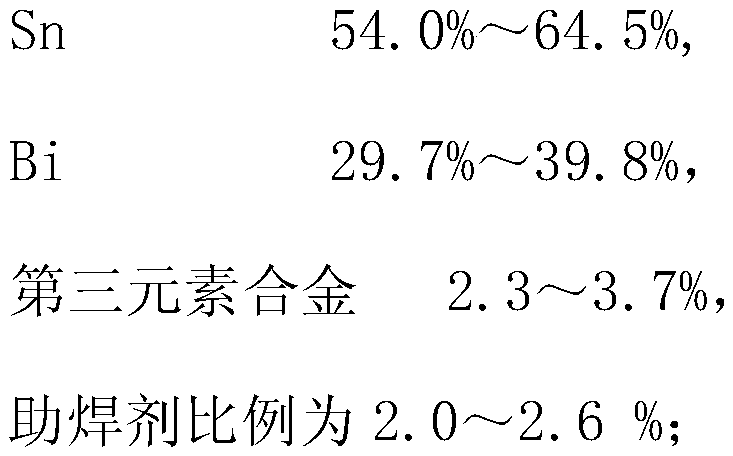

[0039] Table 1: Each component weight composition among the embodiment 1~6:

[0040]

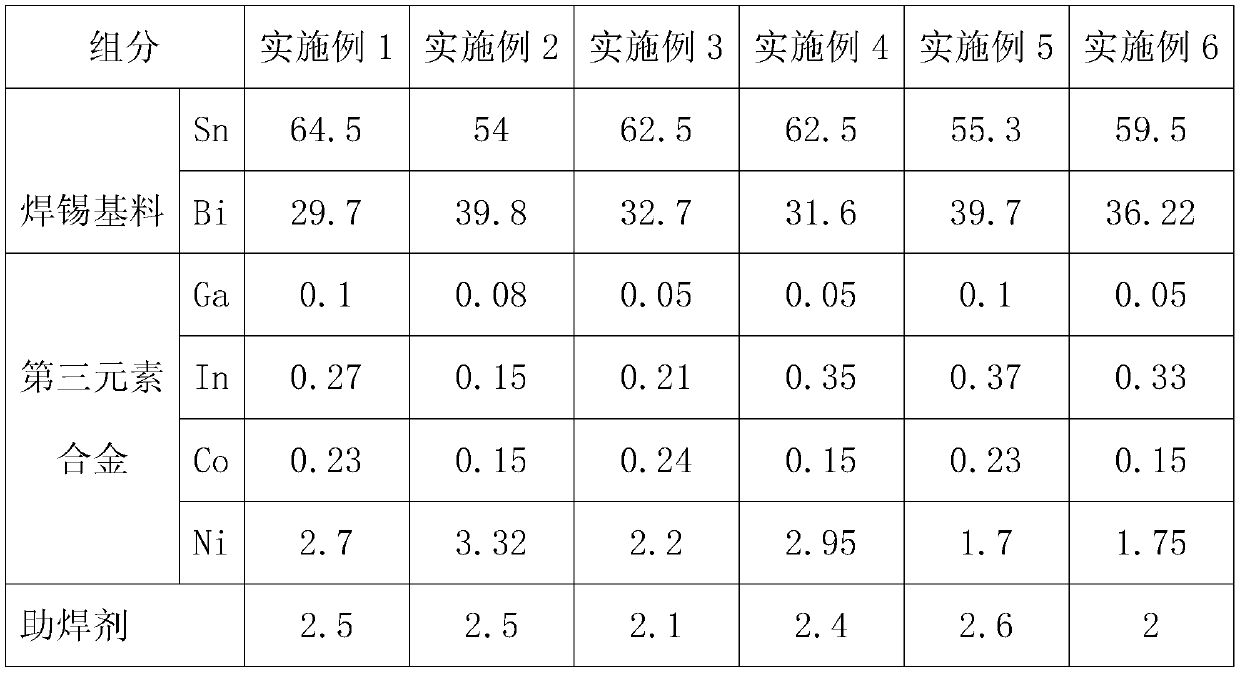

[0041] Table 2: Composition by weight percentage of each component of flux in Examples 1-6:

[0042]

[0043]

Embodiment 1~2

[0044] The implementation scheme of embodiment 1~2:

[0045] A preparation method of environment-friendly ultra-fine solder wire, comprising the steps of:

[0046] 1) Weigh the raw materials of Sn, Bi and the third element alloy according to the weight ratio, melt and heat to 380-400°C, keep warm, stir, stand still, remove slag, and cast a cylindrical billet with a specification of Φ84×180mm;

[0047] 2), put the Φ84×180mm billet into a 350-ton large deformation extruder with a diameter of Φ9mm, and put rosin welding oil into the rosin barrel at a ratio of 2.3%;

[0048]3) Control the temperature of the rosin barrel at 110°C, the billet temperature at 100°C, and the extrusion force at 150kg / cm 2 , the wire output speed is about 1.5m / min, adjust the neutrality of the rosin nozzle and the size of the gap and test the flux content of the thick wire until the flux content of the core of the thick tin wire is 2.0-2.6%;

[0049] 4) Pass the thick tin wire of Φ9mm into 16 near-fini...

Embodiment 3~4

[0059] The implementation scheme of embodiment 3~4:

[0060] A preparation method of environment-friendly ultra-fine solder wire, comprising the steps of:

[0061] 1) Weigh the raw materials of Sn, Bi and the third element alloy according to the weight ratio, melt and heat to 380-400°C, keep warm, stir, stand still, remove slag, and cast a cylindrical billet with a specification of Φ84×180mm;

[0062] 2), put the Φ84×180mm billet into a 350-ton large deformation extruder with a diameter of Φ9mm, and put rosin welding oil into the rosin barrel at a ratio of 2.1%;

[0063] 3) Control the temperature of the rosin barrel at 110°C, the billet temperature at 100°C, and the extrusion force at 150kg / cm 2 , the wire output speed is about 1.5m / min, adjust the neutrality of the rosin nozzle and the size of the gap and test the flux content of the thick wire until the flux content of the core of the thick tin wire is 2.0-2.6%;

[0064] 4) Pass the thick tin wire of Φ9mm into 16 near-fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com