Composite plate emery wire cutting machine

A composite material, emery wire technology, used in stone processing tools, stone processing equipment, work accessories, etc., to achieve the effect of improving life, reducing friction, and reducing horizontal and vertical vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

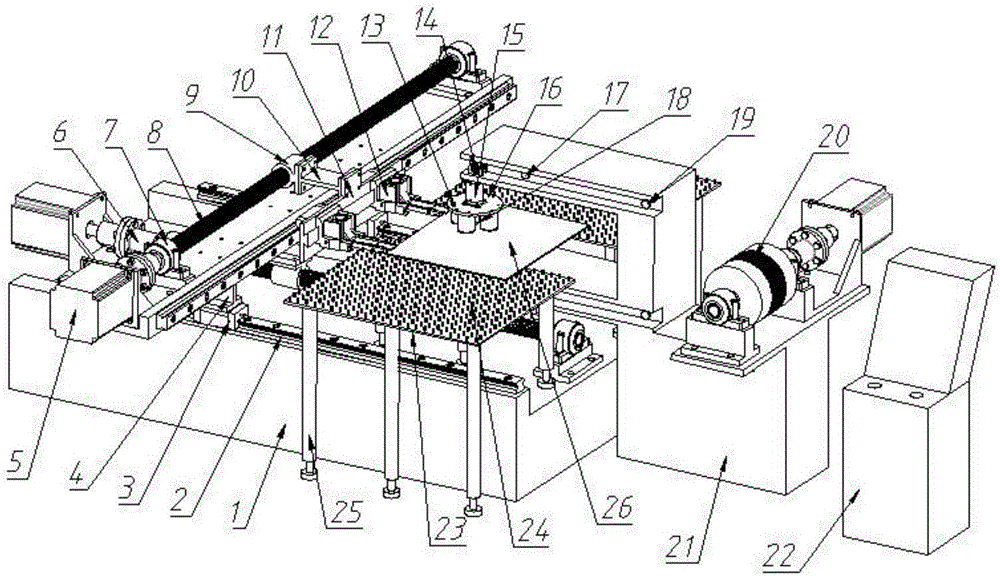

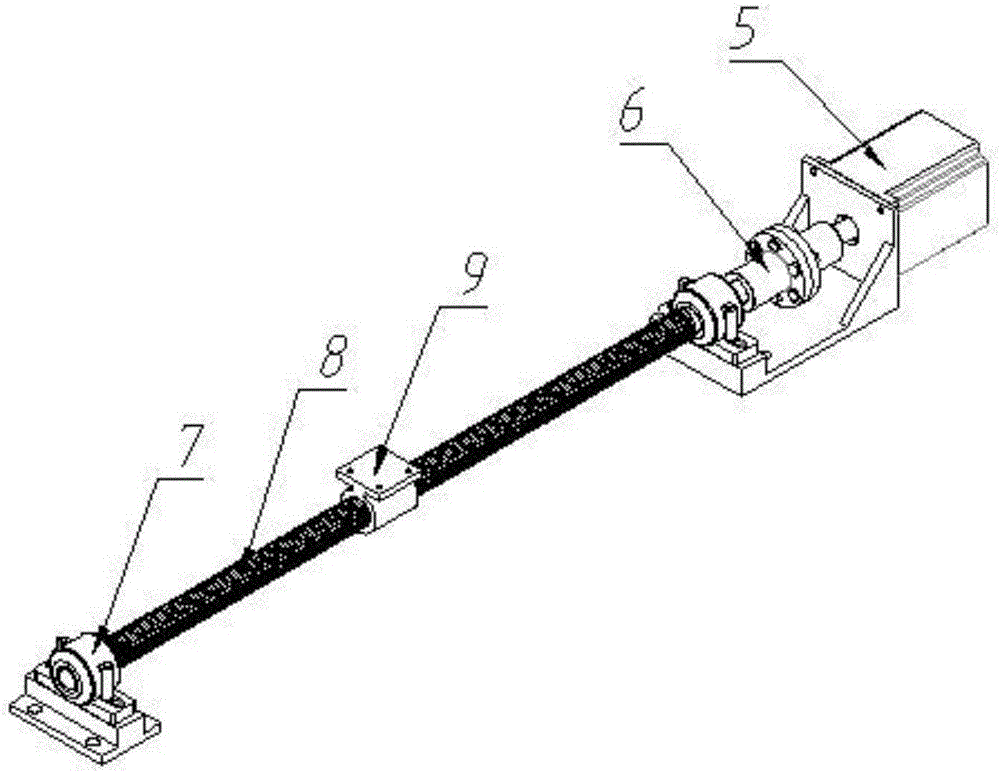

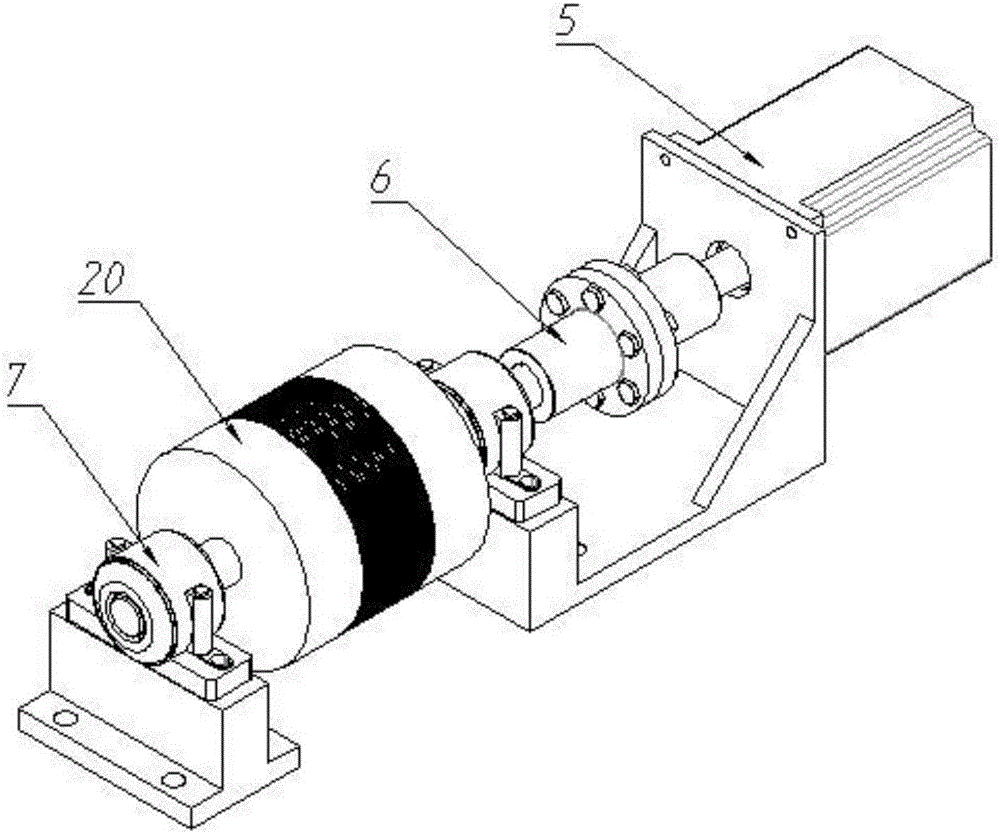

[0045] Attached below Figure 1 to Figure 13 And embodiment the application of the present invention is described further:

[0046] The present invention is a new type of emery wire cutting machine aimed at cutting non-metallic plates, especially composite material plates. It solves the problem of cutting non-metallic plates, especially the problem of cutting non-metallic plates with complex geometric shapes. The metal plate is cut into various shapes, with high automation, high cutting efficiency and high cutting precision; the invention cuts non-metallic plates through the corundum micropowder covered on the surface of the corundum wire. The pneumatic clamp on the coordinate workbench should clamp the non-metallic plate well, and the pre-pressure of the steel ball on the floating pressure damping device should press against the non-metallic plate and press it on the fixed supporting device, so as to reduce the vibration of the non-metallic plate , the wire feeding mechanism...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com