Tubular resistor applicable to high current

A resistor, high current technology, applied in the direction of resistors, resistor parts, circuits, etc., can solve the problems of the overall volume of the unfavorable high current resistor, the large space area of the resistor chip, and the small elastic modulus of the resistor chip, etc. Compact structure, good impact resistance, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

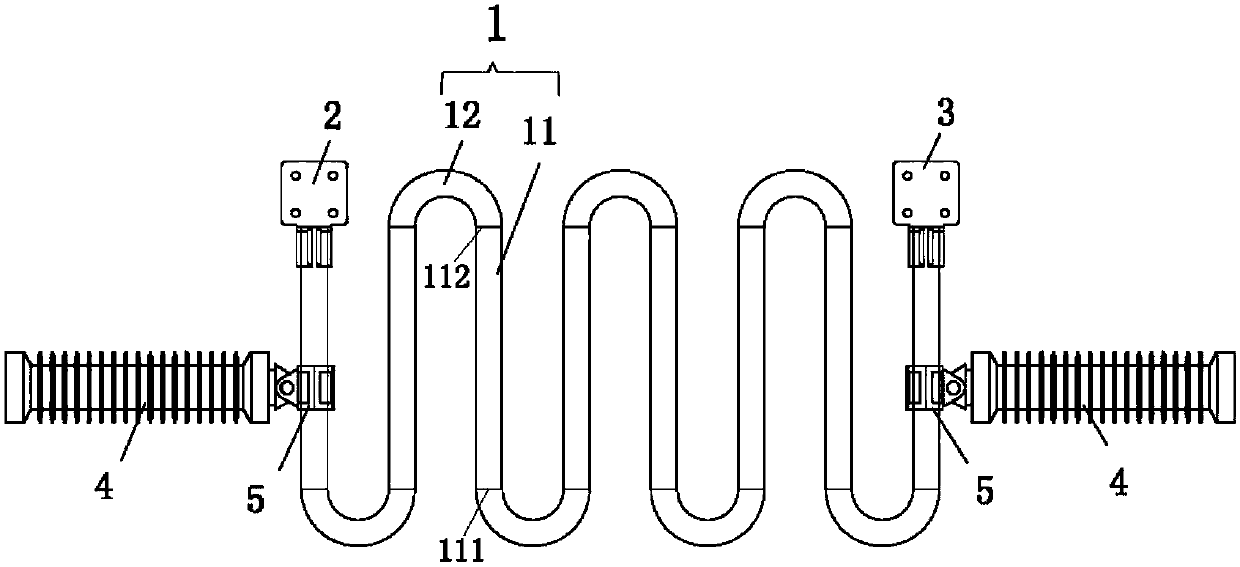

[0020] A tubular resistor suitable for high current in this embodiment, such as figure 1 As shown, there is a tube body 1 for generating resistance. The tube body 1 is a hollow circular tube with a large cross-sectional area, which can withstand multiple impacts of high current. The pipe body 1 has a plurality of bent sections 12, and the material of the pipe body is aluminum-nickel alloy.

[0021] Specifically, the pipe body 1 is bent into a continuous coil, and the coil has eight straight sections 11 and seven curved sections 12, each straight section 11 has the same length, and is aligned parallel to the vertical axis on the same plane. Arranged, the upper end of each straight section 11 is the first end 111, the lower end is the second end 112, and a curved section 12 is used to connect the first end 111 of the first and second straight sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com