Method for manufacturing energy storage underground water tank and support member for energy storage underground water tank

A technology of supporting components and manufacturing methods, applied in underwater structures, water conservancy projects, infrastructure projects, etc., can solve the problems of complex stress on pools, limited energy storage of air conditioning systems, and high construction costs, and is conducive to large-scale construction , meet the energy supply demand, reduce the effect of construction work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

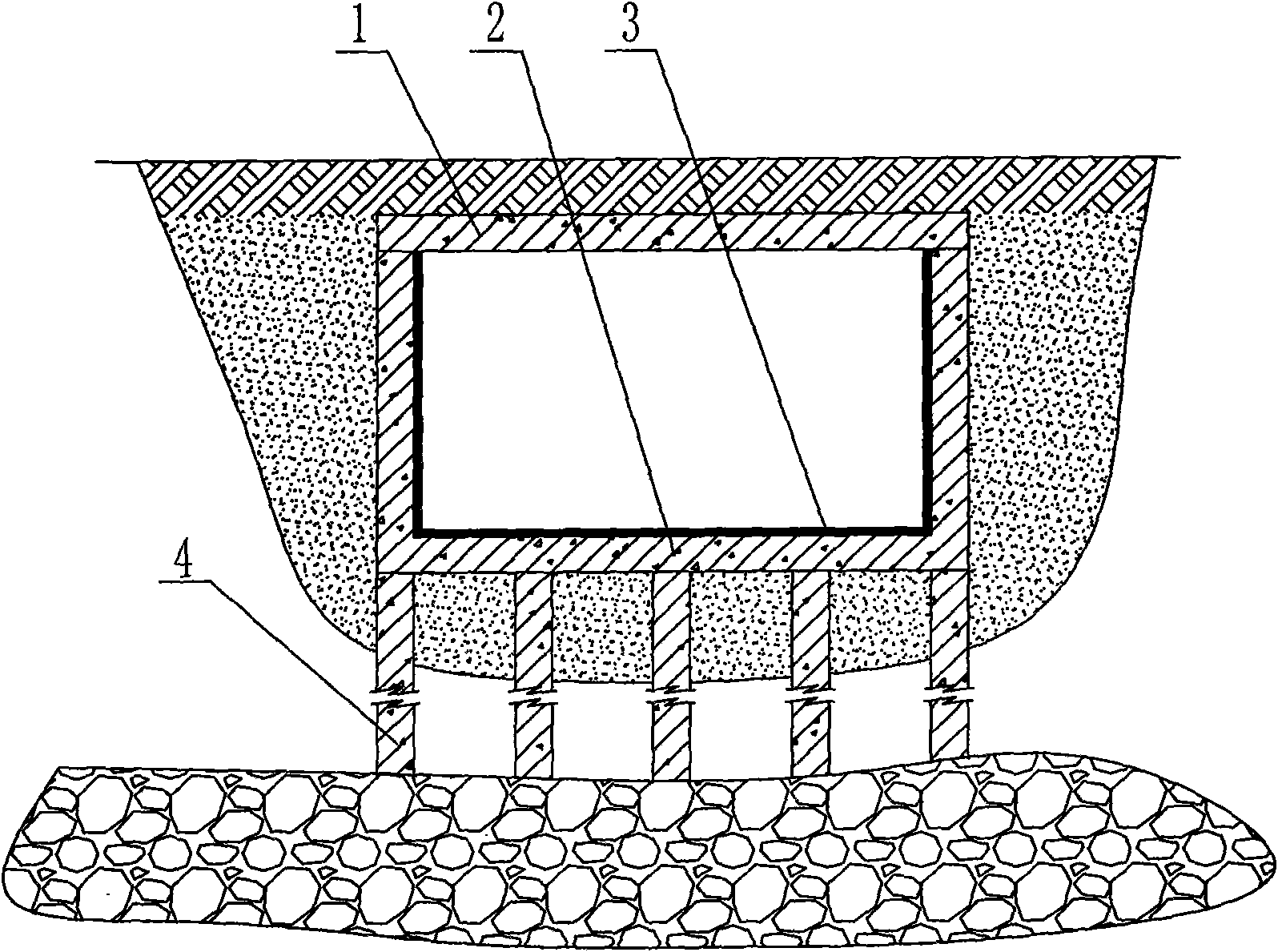

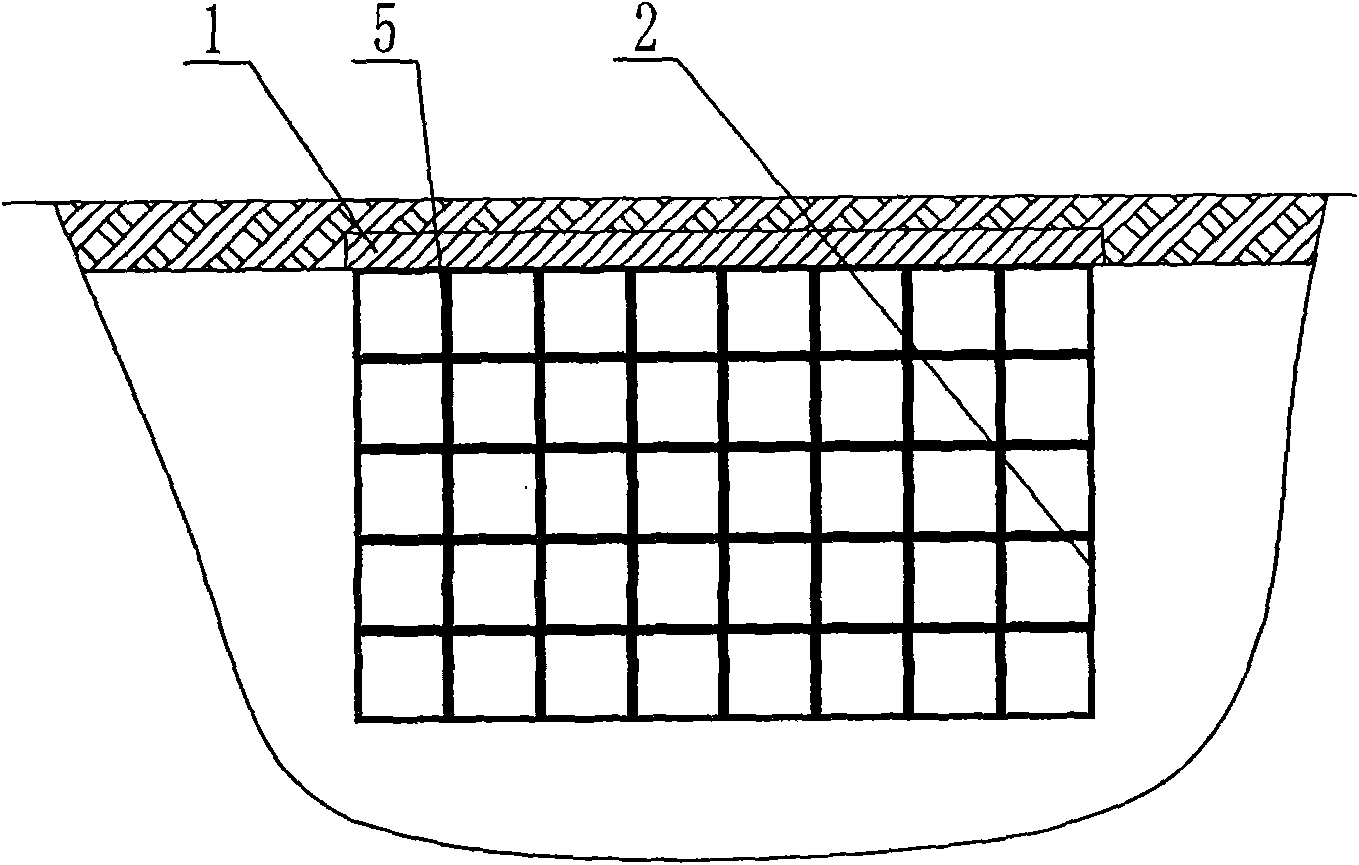

[0024] See figure 2 Shown, the manufacture method of energy-storage underground pool of the present invention, carries out according to the following steps:

[0025] (1) Make the area of the pool according to the required area, and excavate a pit with a depth of less than 0.5m on the ground as the pool. If a 20mX10mX10m energy storage pool is required, first excavate a 20mX10mX0.5m pit as the pool. The area of the pool can be Set as desired.

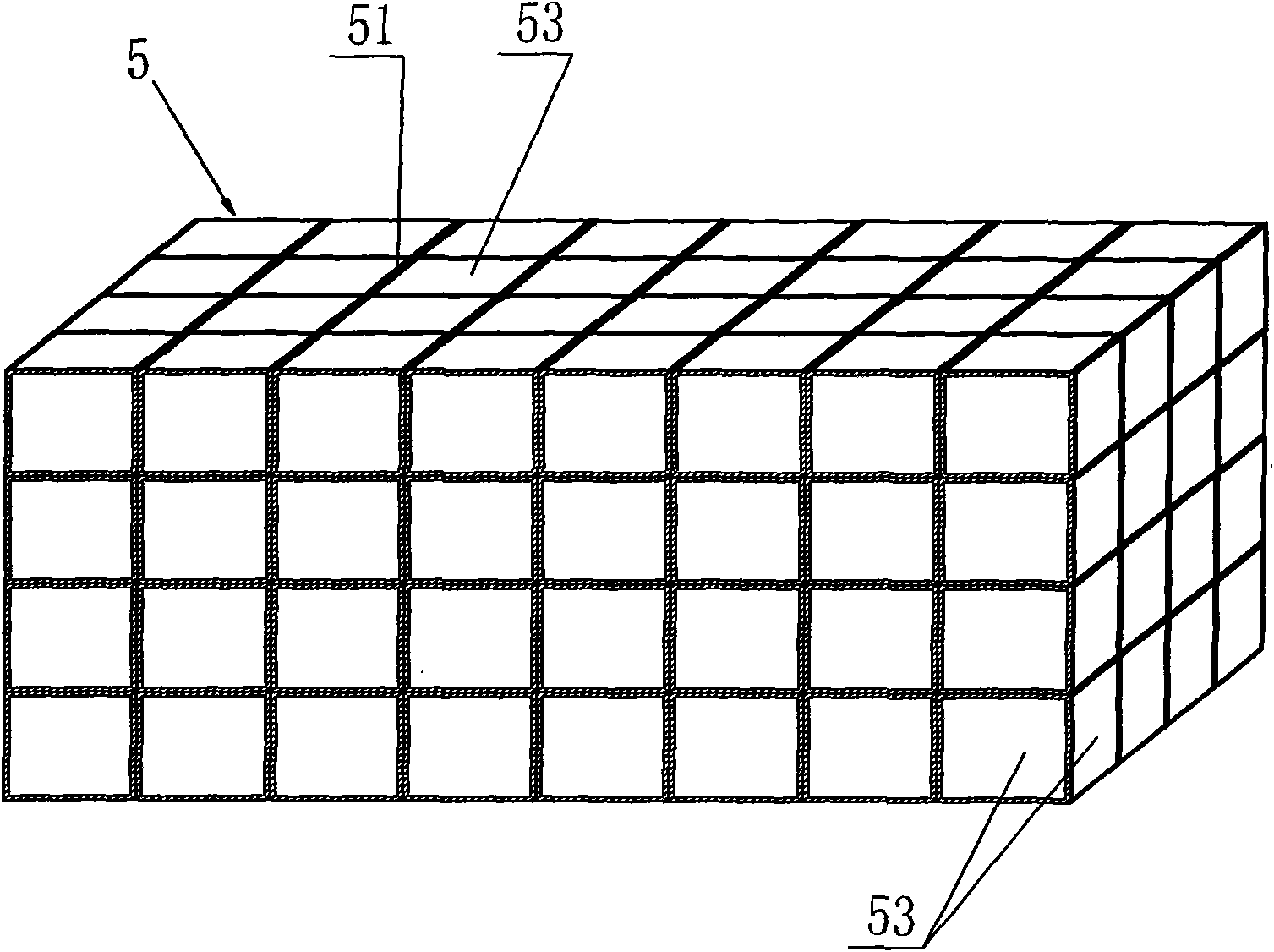

[0026] (2) Place the support member composed of more than six adjacently connected support modules in the pool. The support module is a prefabricated part made of reinforced concrete, and the bottom of the pool is covered with multiple support modules. Each support module It is a frame structure with more than six sides, and the upper and lower sides and at least two sides of each support module are provided with openings communicating with the hollow core, and at least one surface of each support module facing the surrounding wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com