Energy-saving tunnel drying oven

A technology of oven and tunnel, which is applied in the field of energy-saving tunnel oven, which can solve the problems of wasting waste heat of air, low thermal efficiency of electric energy, heat loss, etc., and achieve the effects of reducing heat loss, saving energy and reducing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

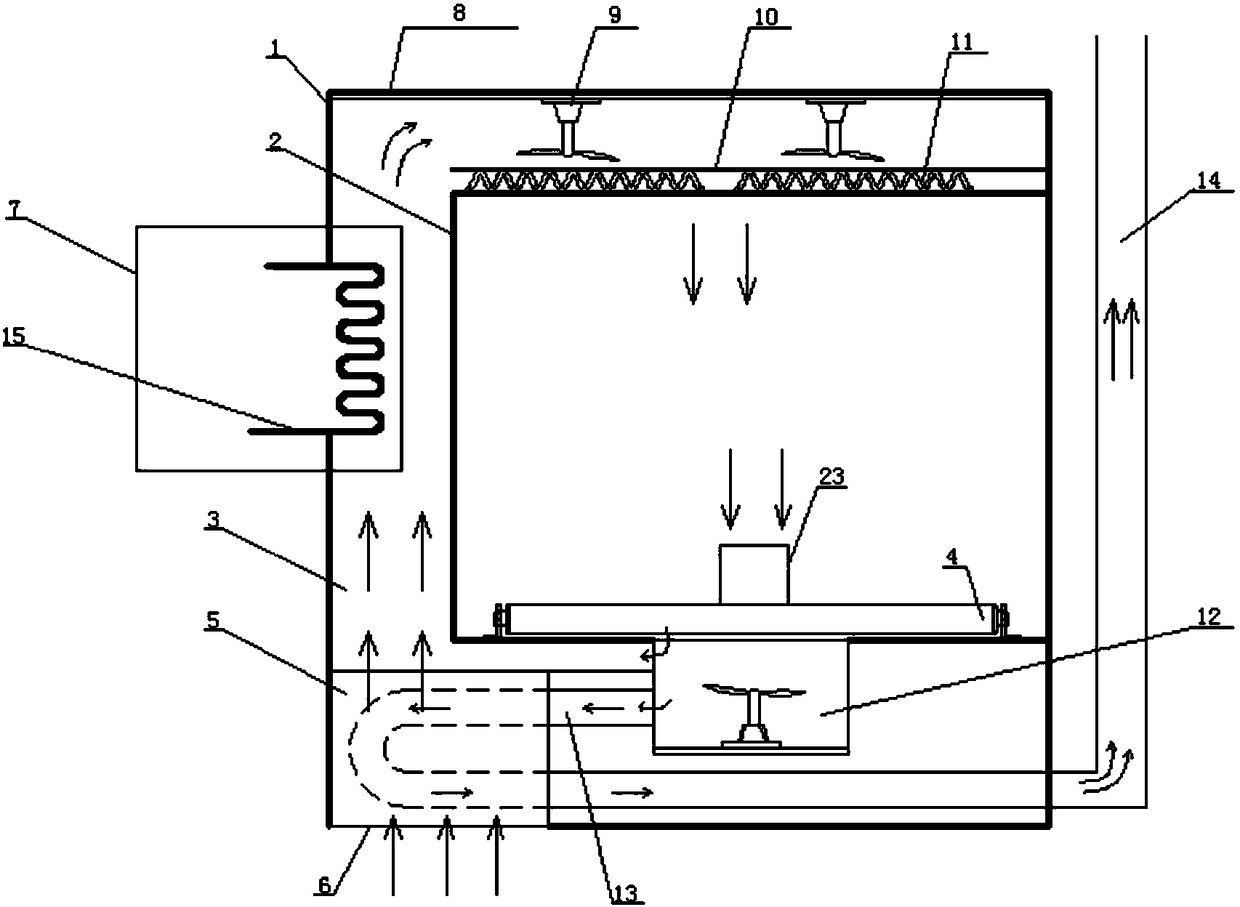

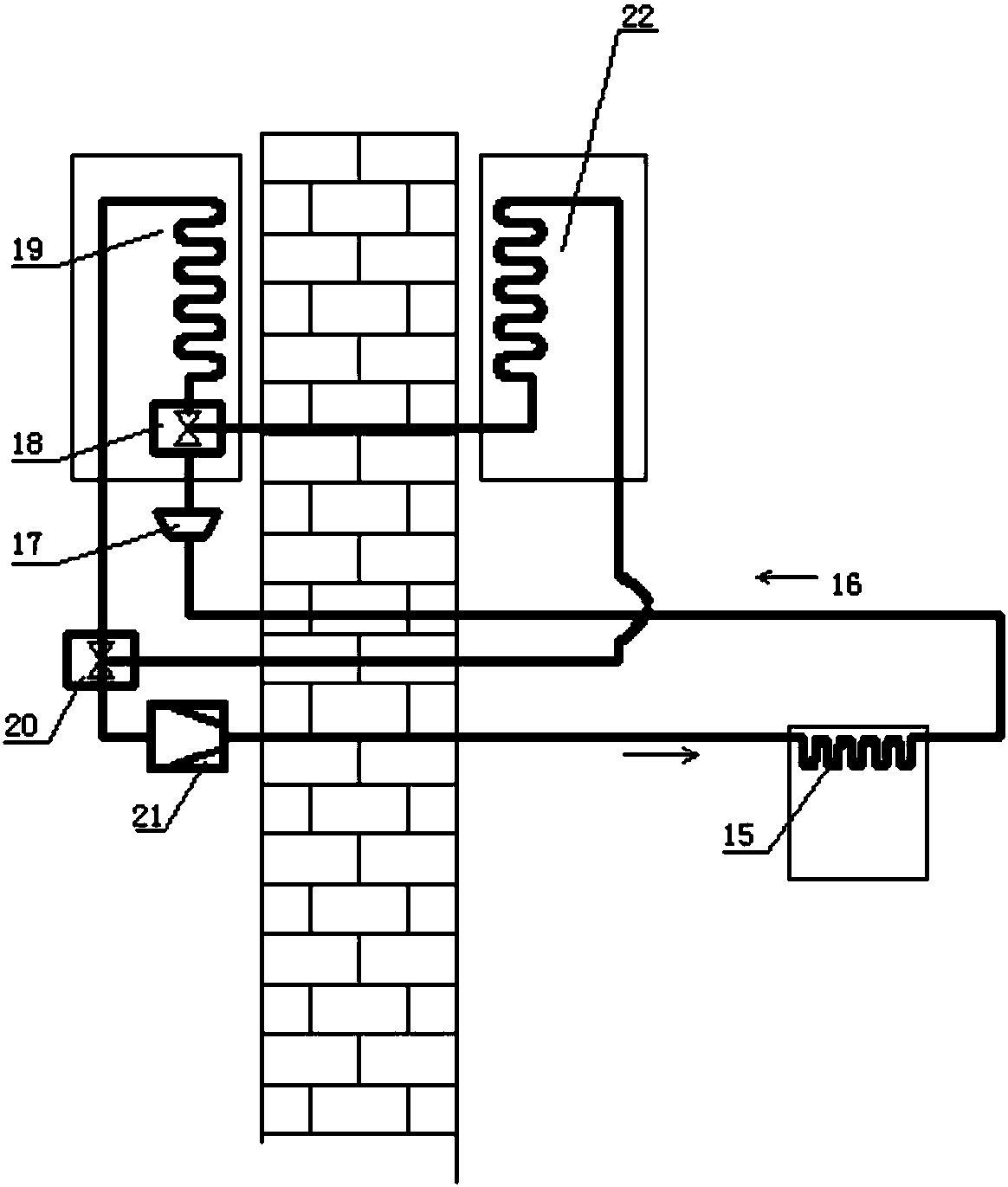

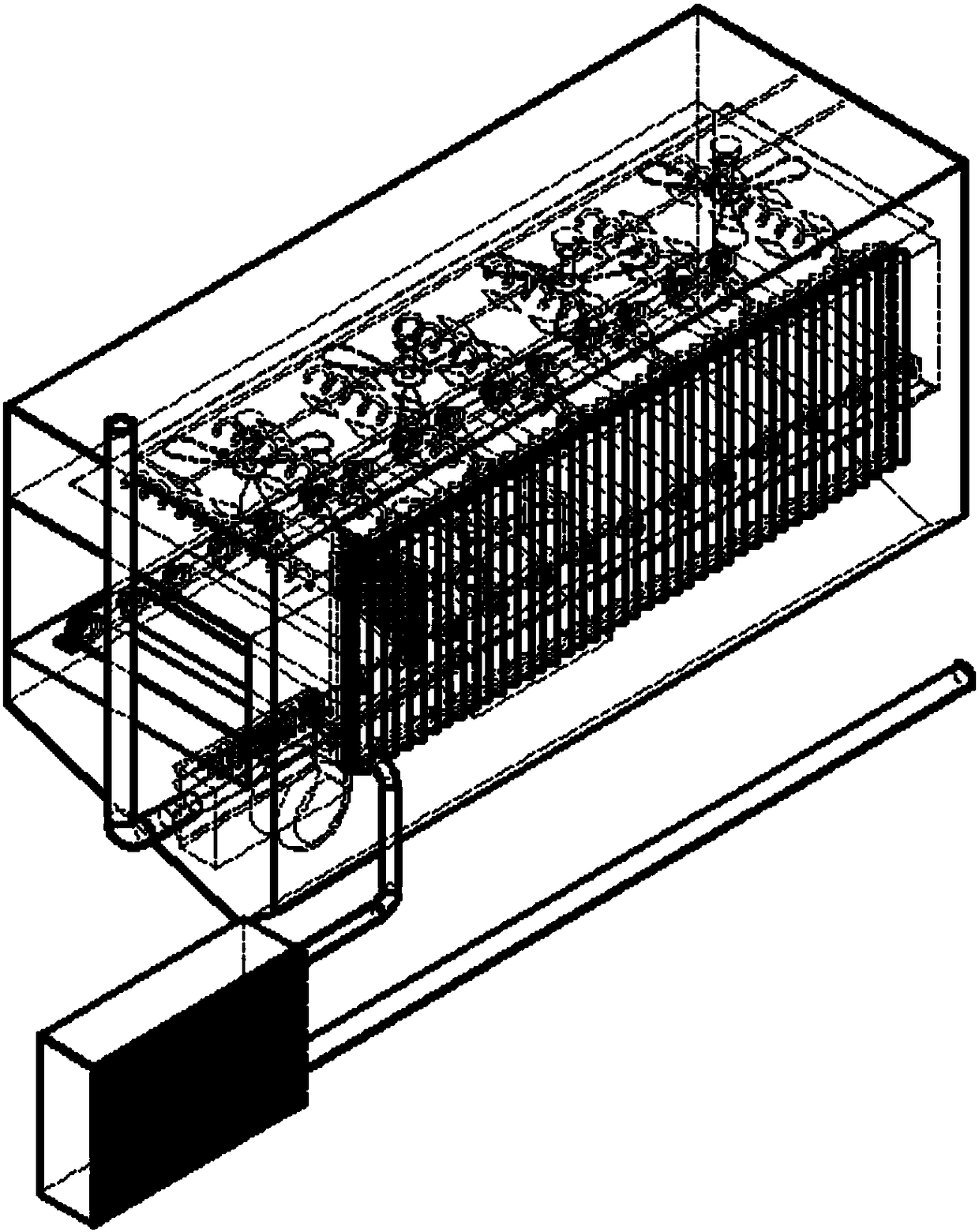

[0026] refer to figure 1 , figure 2 and image 3 The present invention will be further described.

[0027] like figure 1 As shown, this embodiment includes an outer casing 1, an inner casing 2, an air channel 3, a conveyor belt 4, a heat exchanger 5, an air intake channel, a heat pump system 7, a fan bracket 8, a fan 9, a baffle 10, and a heating device 11. , Air flow distributor 12 , connecting pipe 13 and exhaust pipe 14 .

[0028] The outer casing 1 is a hollow square box, which is composed of the front side plate, the rear side plate, the left side plate, the right side plate, the upper side plate and the lower side plate of the outer casing 1. The outer casing 1 is the outermost layer of the oven. The outer casing 1 is a carrier for the oven to work, and the cavity of the outer casing 1 is also a space for heat energy circulation.

[0029] The left side plate, the right side plate, the upper side plate and the lower side plate of the inner casing 2 enclose the struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com