Patents

Literature

64results about How to "Improve heating and drying effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

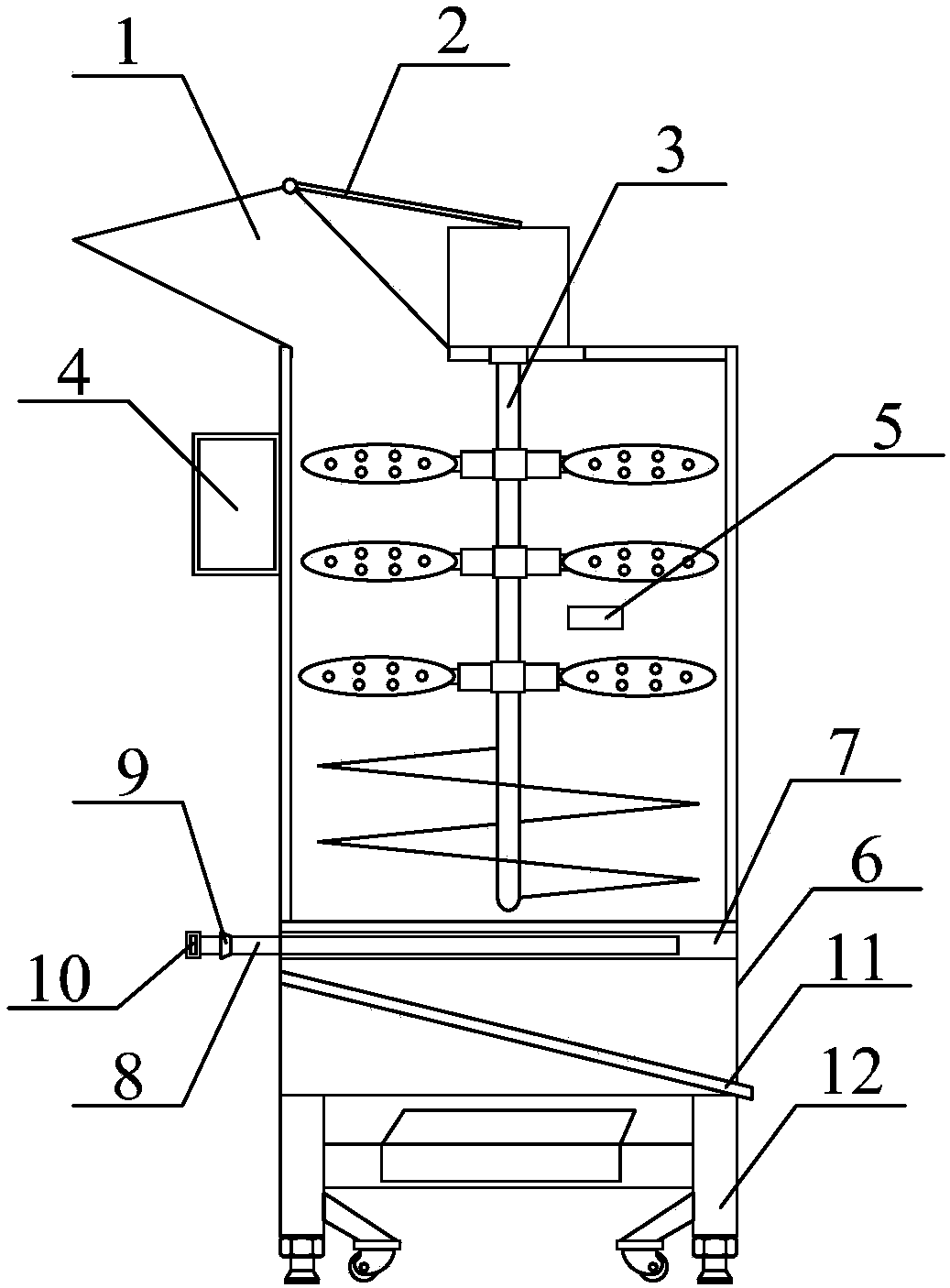

Agricultural grain storage device providing convenience for discharging

InactiveCN108738734AEasy to storeAvoid accumulationAgriculture tools and machinesClimate change adaptationGrain storageAgricultural engineering

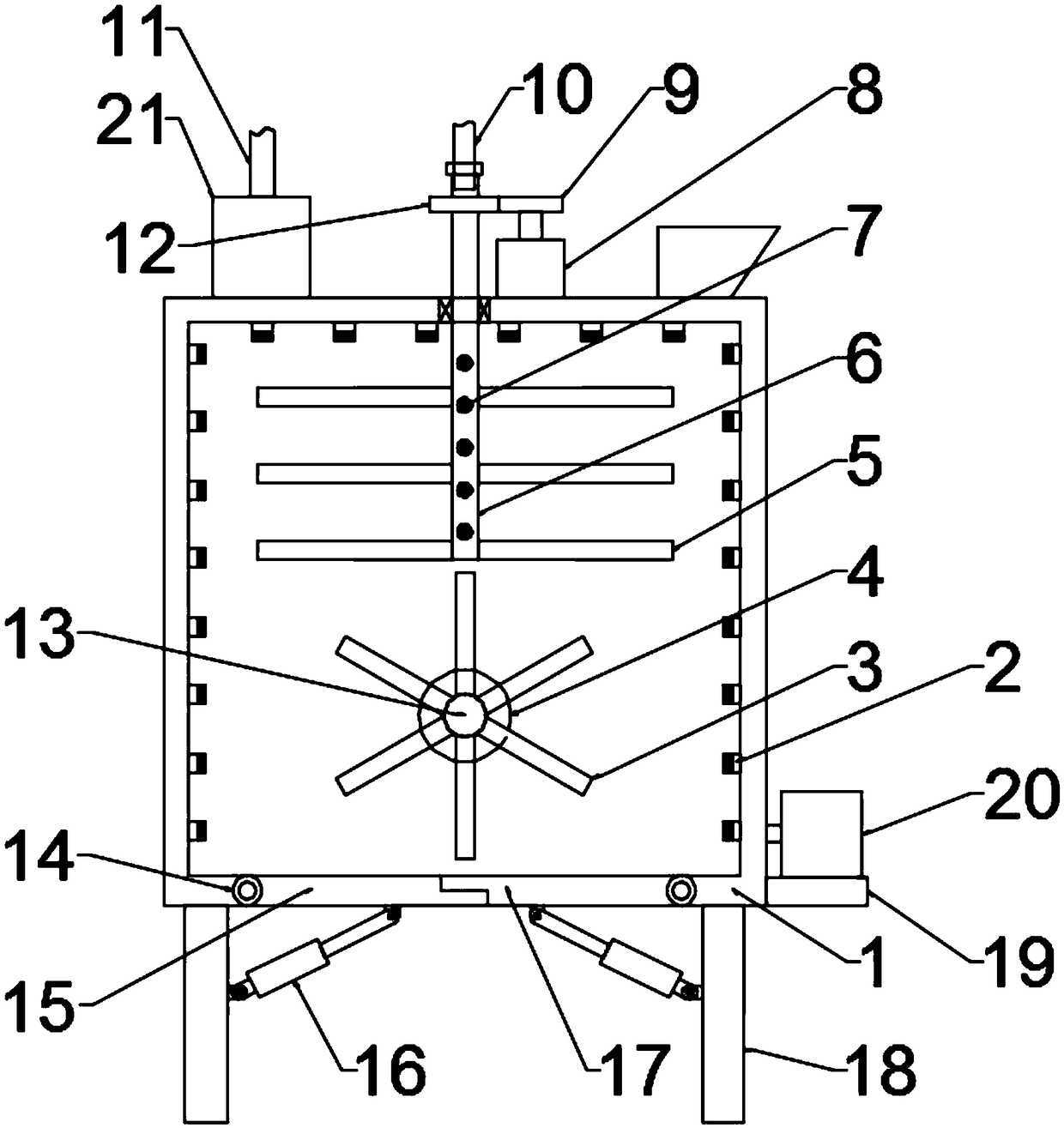

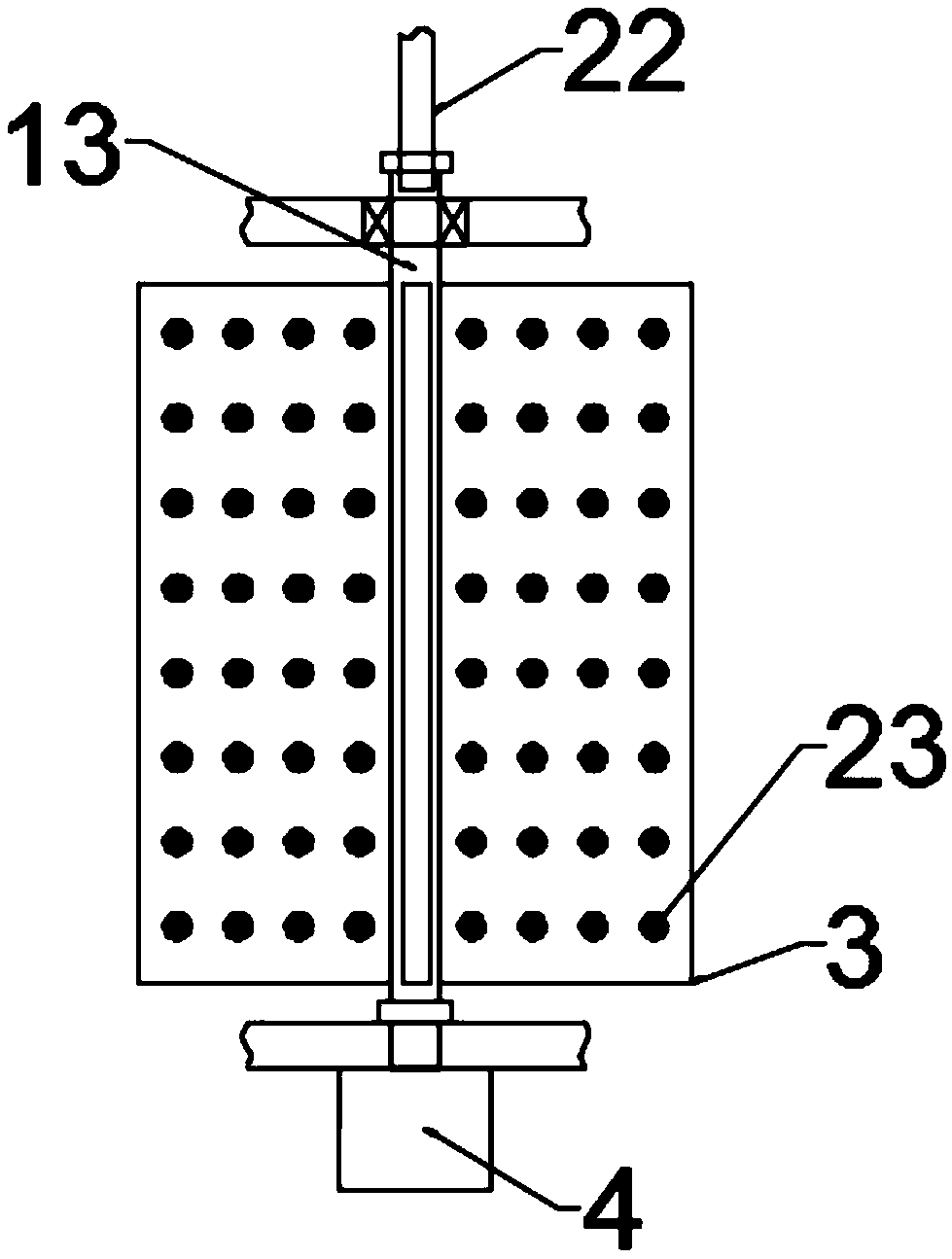

The invention discloses an agricultural grain storage device providing convenience for discharging. The device comprises a storage box, a first movable plate, a second movable plate, electric push rods, a stirring shaft, stirring rods, a first gear, a second gear, a hollow rotation shaft, a second motor, hollow fan plates and a second air heater. According to the agricultural grain storage device,by arranging a motor, the first gear, the second gear, the stirring shaft, the stirring rods, the second motor and the fan plates, grain in the storage box is stirred by the stirring rods, and the situation is avoided that the humidity of the grain is increased due to grain stacking, and accordingly storage is inconveniently conducted; meanwhile, the grain at the bottom of an inner cavity of thestorage box is overturned continuously by the fan plates, ventilation and moisture volatilization are conducted conveniently, and the situation is avoided that the moisture is increased due to aerobicrespiration of the grain, and accordingly storage is inconveniently conducted; by arranging an air heater and the second air heater, heating and drying are comprehensively conducted, and convenienceis provided for grain storage; by arranging the first movable plate, the second movable plate and the electric push rods, the grain at the bottom of the storage box is conveniently and preferentiallydischarged, and the situation is avoided that the moisture is increased due to long-time storage of the grain, and accordingly the grain mildews.

Owner:史积贵

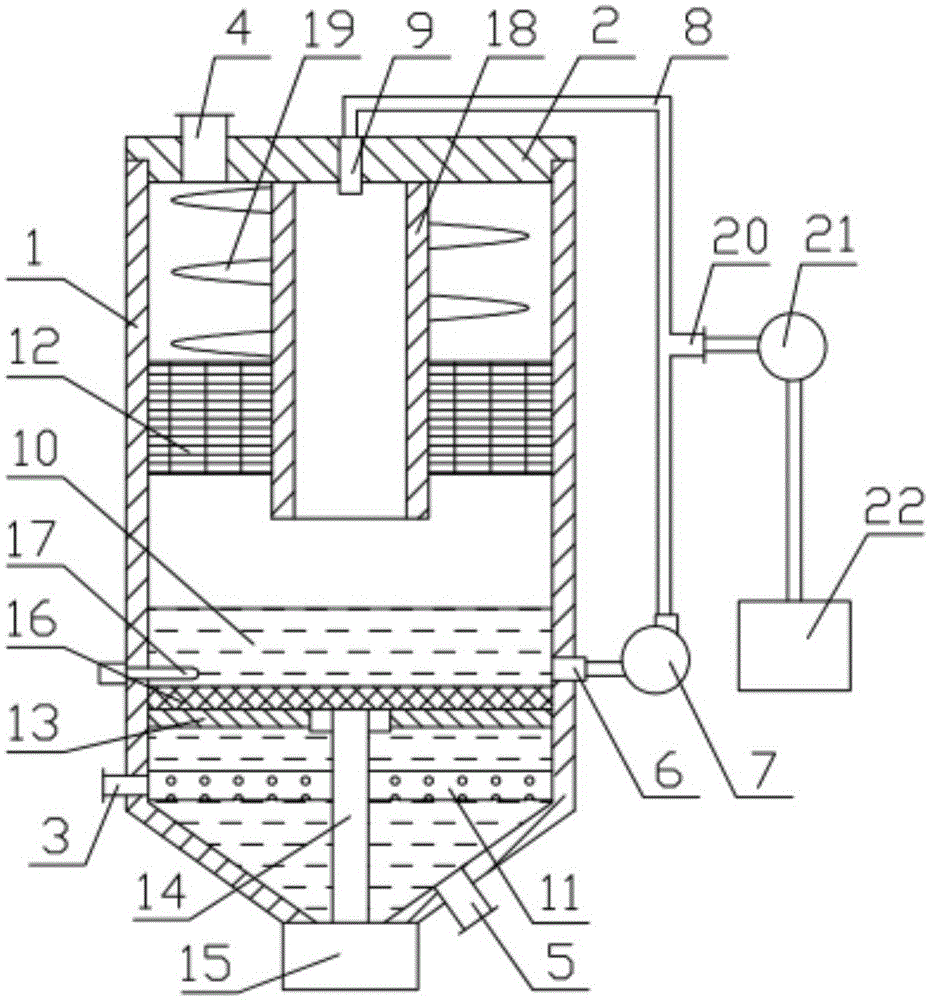

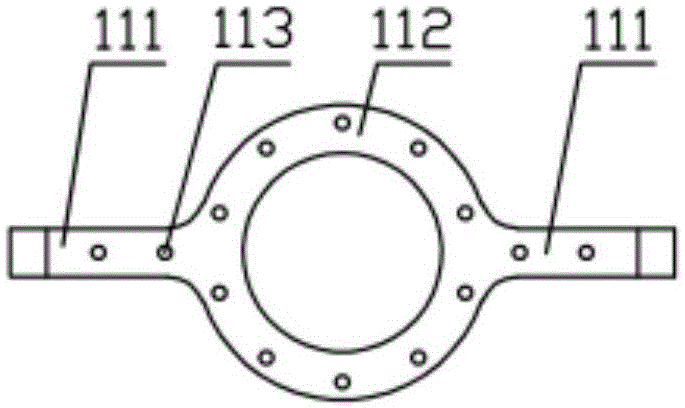

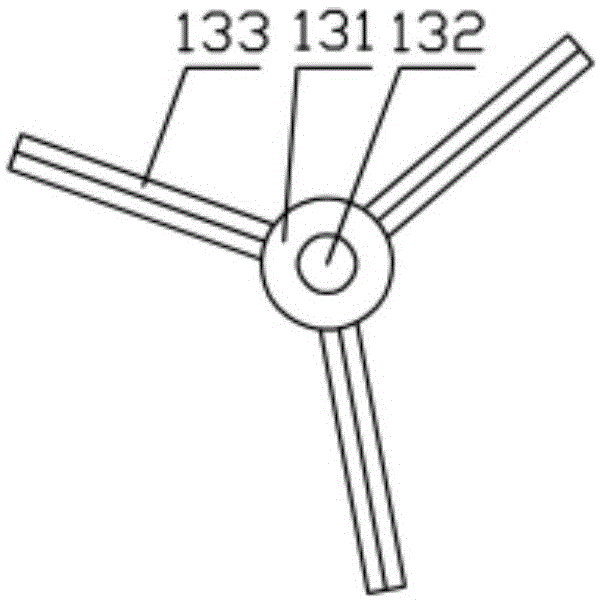

Silt treatment device for water conservancy project

ActiveCN112536138AImprove filtration efficiencyGood heating and drying effectSievingScreeningEnvironmental geologyStructural engineering

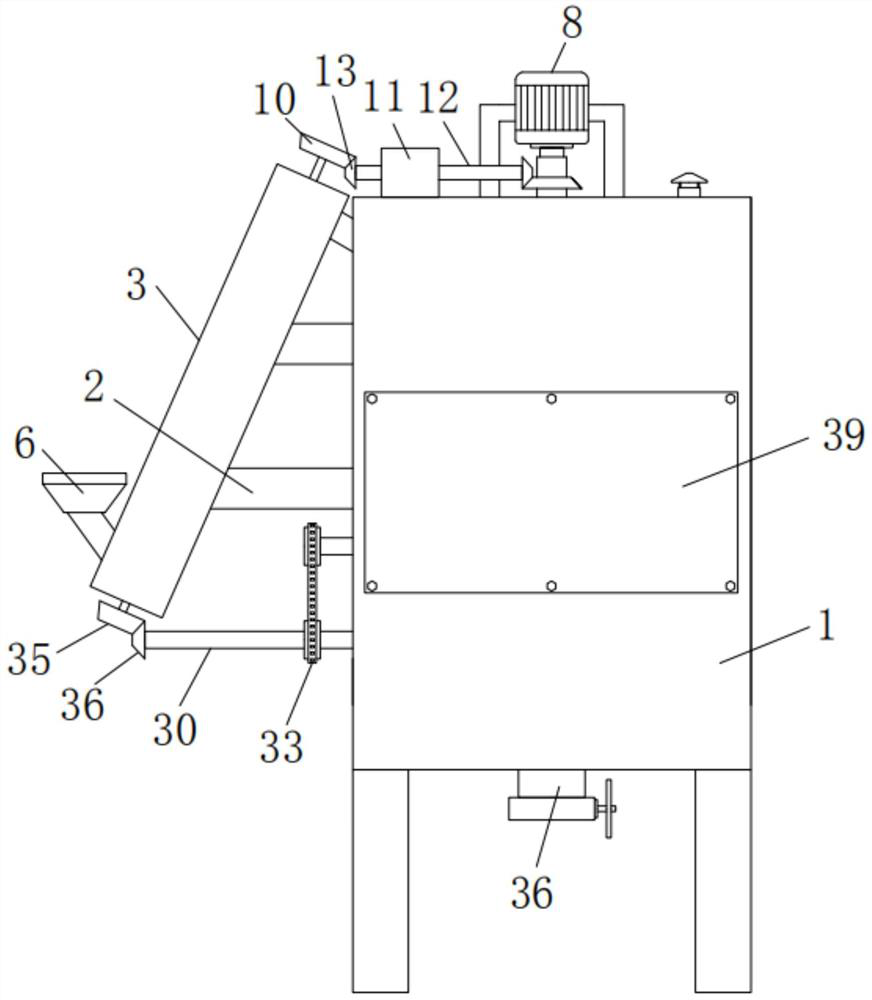

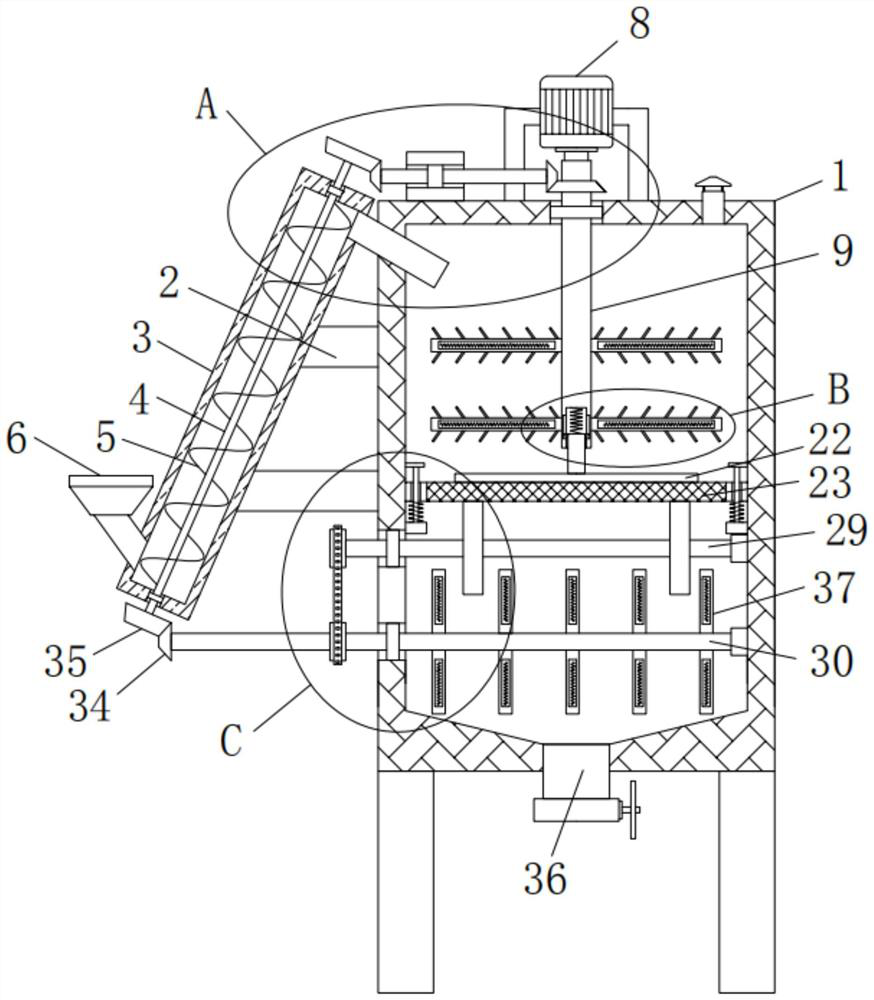

The invention discloses a silt treatment device for a water conservancy project. The silt treatment device comprises a barrel, two supports are fixedly installed on one side of the barrel, the same material conveying pipe is fixedly installed on the sides, away from the barrel, of the two supports, the material conveying pipe is obliquely arranged, a rotating shaft is arranged in the material conveying pipe, the rotating shaft is fixedly sleeved with a spiral impeller, round holes are formed in the inner wall of the top and the inner wall of the bottom of the material conveying pipe, the two ends of the rotating shaft penetrate through the corresponding round holes correspondingly, a hopper is fixedly installed on the side, away from the supports, of the material conveying pipe, and a feeding pipe is fixedly installed on the side, close to the barrel, of the material conveying pipe. The device is reasonable in design and good in practicability, can crush and scatter cakes in silt, hasa good separation effect on impurities such as the silt, stones and larger gravels, can quickly filter the silt, improves the silt filtering efficiency and filtering quality, can quickly heat and drythe silt, and good in the silt drying effect, and high in the drying efficiency.

Owner:山东垦水路桥工程有限责任公司

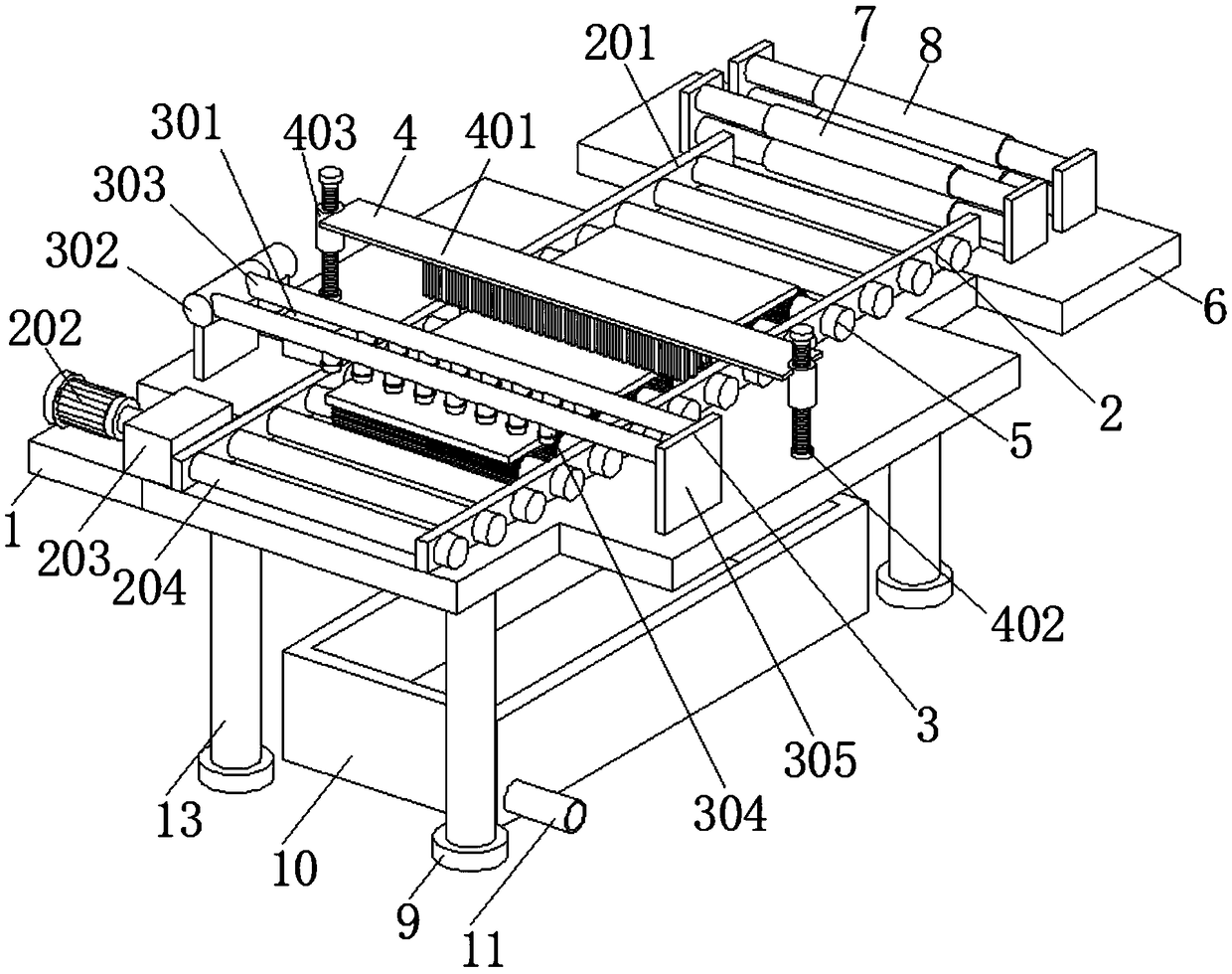

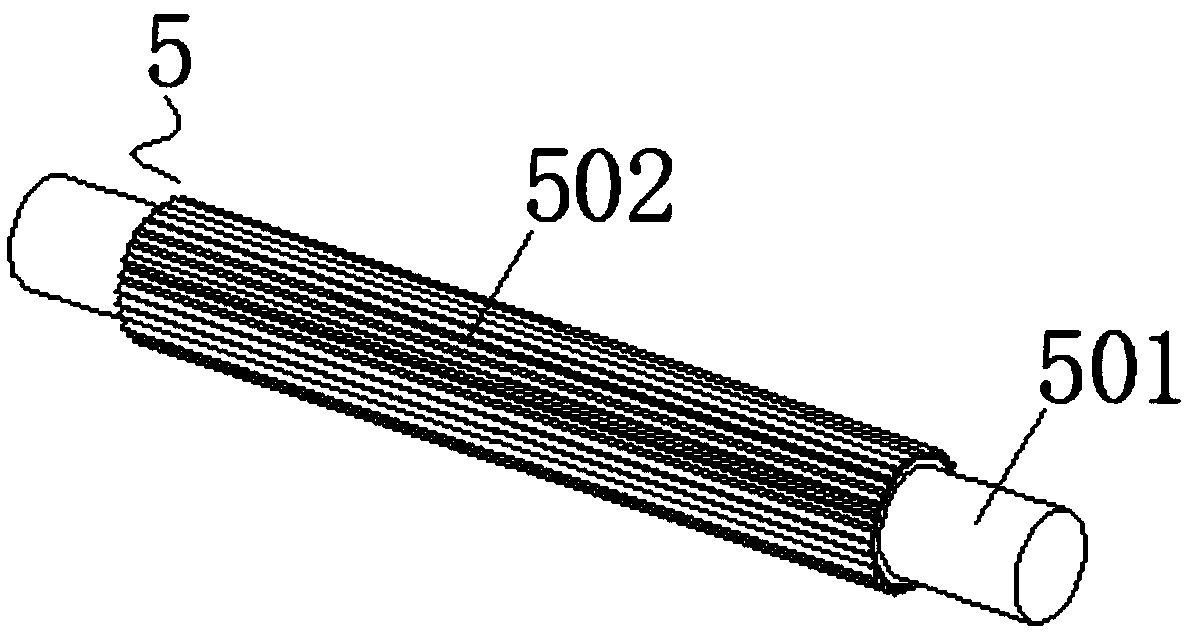

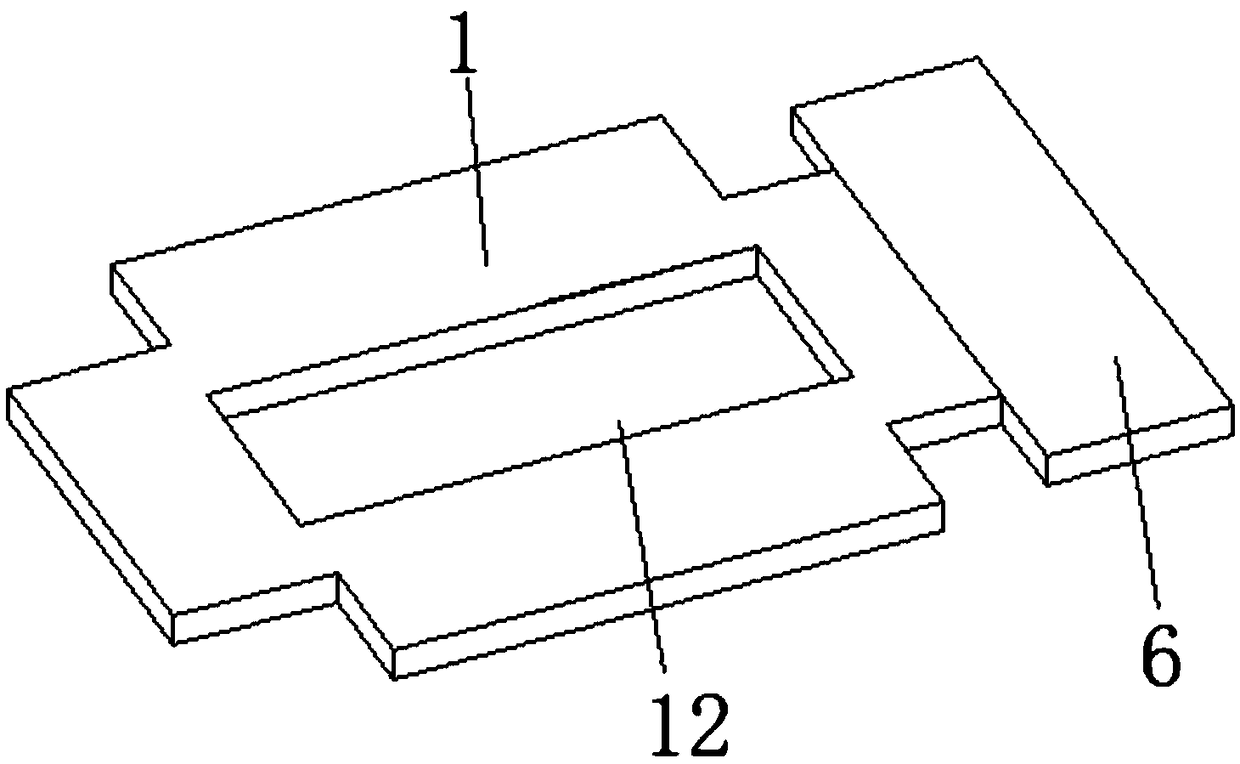

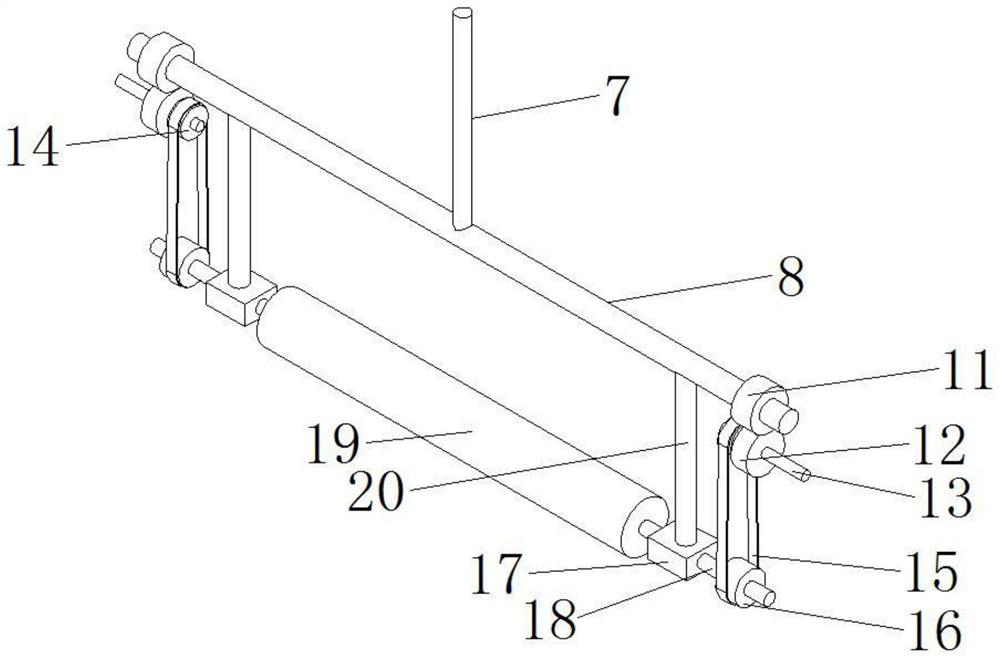

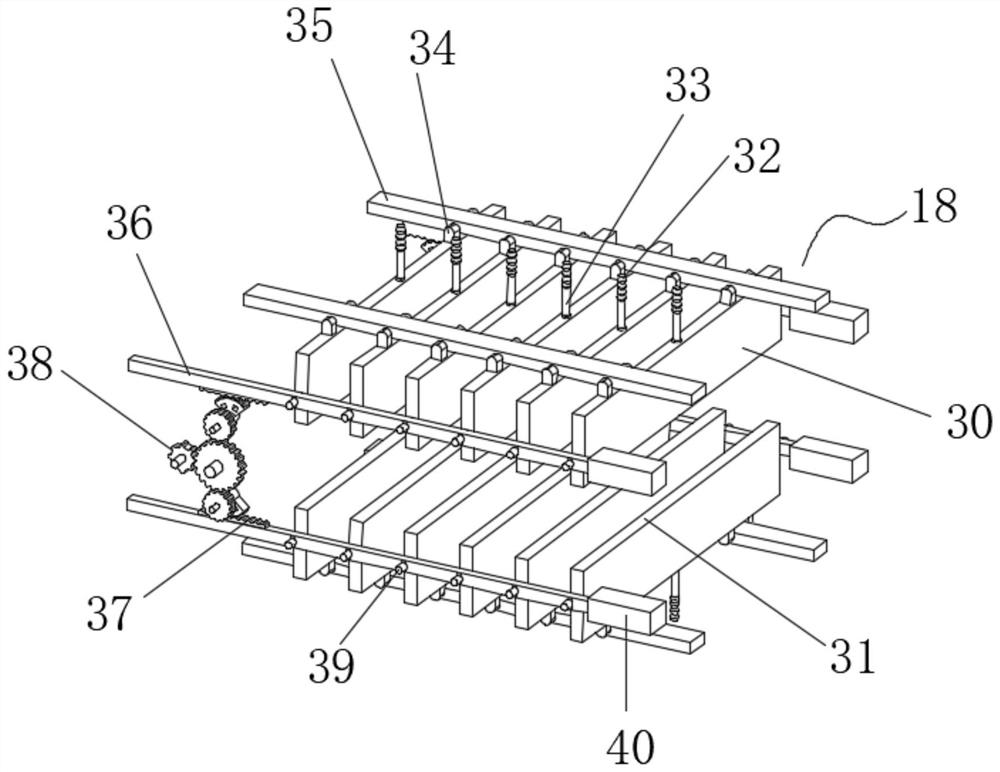

Feeding mechanism for knurling machine

PendingCN109454399AGood effectReduce yieldMetal working apparatusMaintainance and safety accessoriesKnurlingEngineering

The invention discloses a feeding mechanism for a knurling machine. The feeding mechanism comprises a working platform, the top of the working platform is provided with a transmission mechanism, a flushing mechanism is arranged at the top of the working platform, the flushing mechanism is located at the top of the transmission mechanism, the top of the working platform is fixedly connected with abrushing mechanism, the brushing mechanism is located at the top of the transmission mechanism, and a bottom brushing roller is arranged at the top of the working platform. The feeding mechanism solves the problems that an existing knurling machine cannot pre-treat materials, dirt such as residual dust is prone to being left on the materials, the condition of the poor knurling effect in the feeding knurling process is caused, and the yield rate of the product is greatly reduced; and the feeding mechanism of the knurling machine has the advantages of pretreating the materials and improving theyield rate, the structure is simple, operation is convenient, the use cost is low, the knurling effect can be further improved, and the defective percentage of the knurling machine is greatly reduced.

Owner:浙江中诺智能机械有限公司

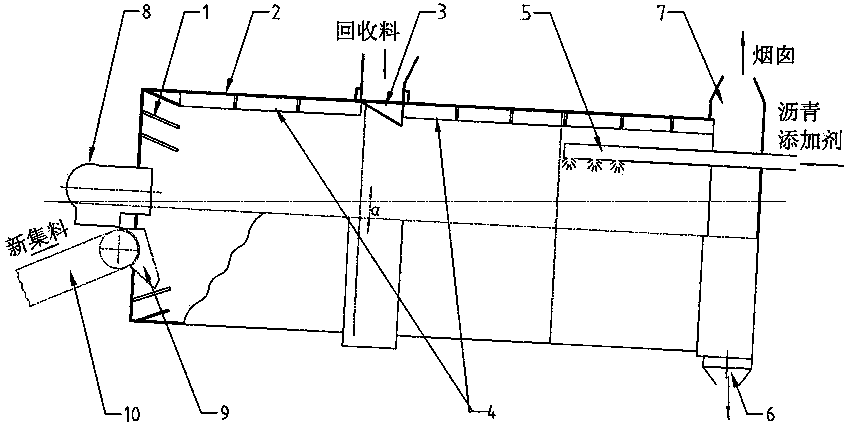

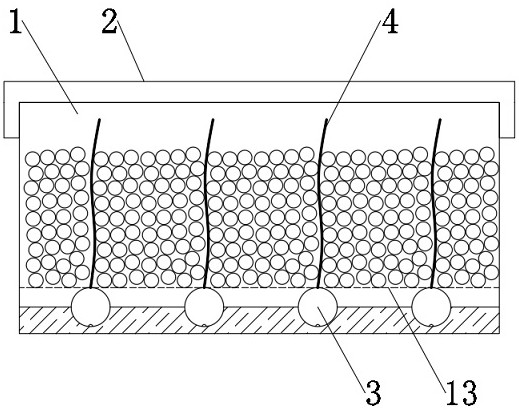

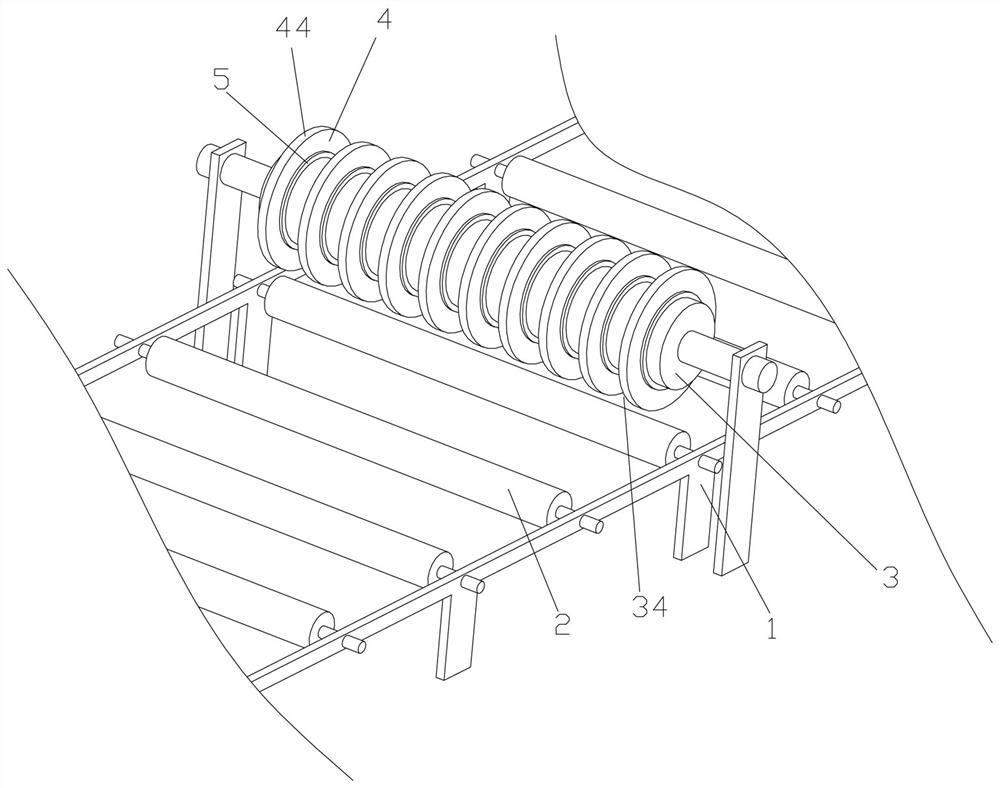

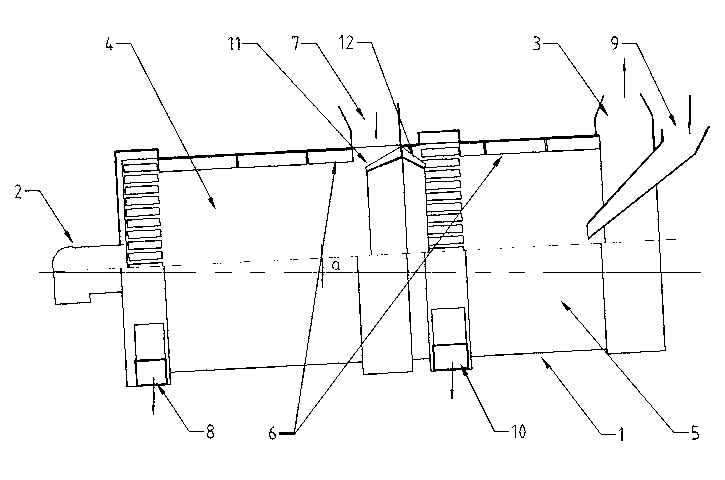

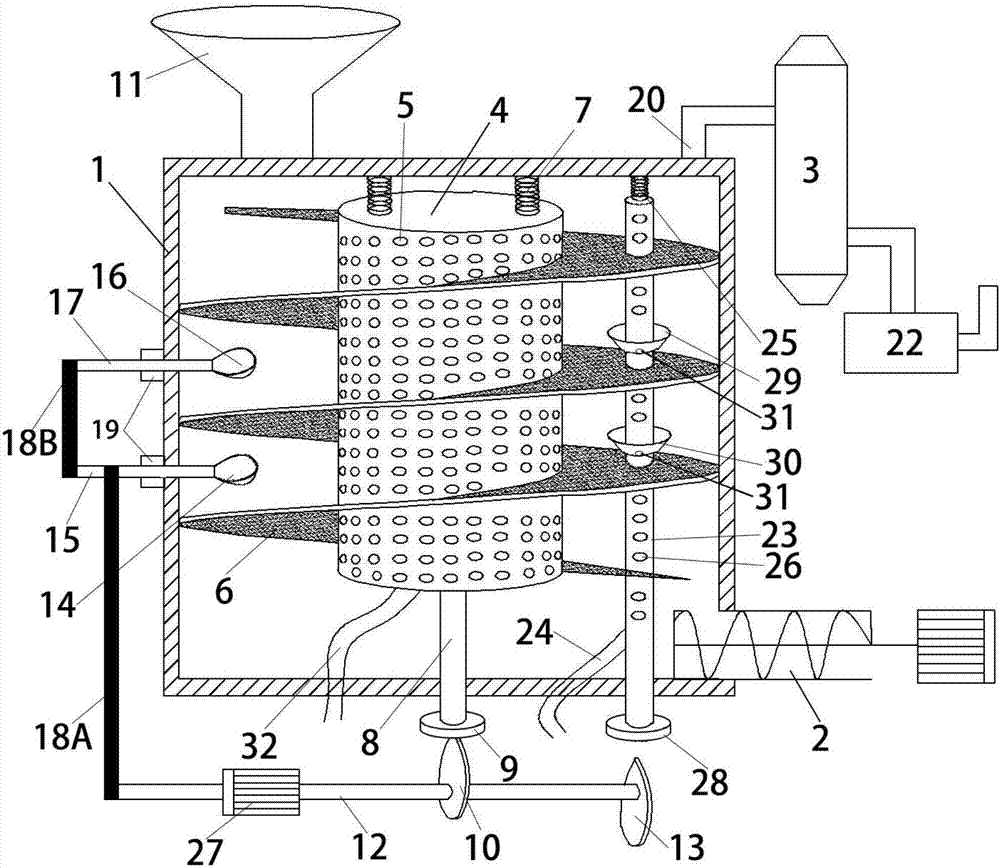

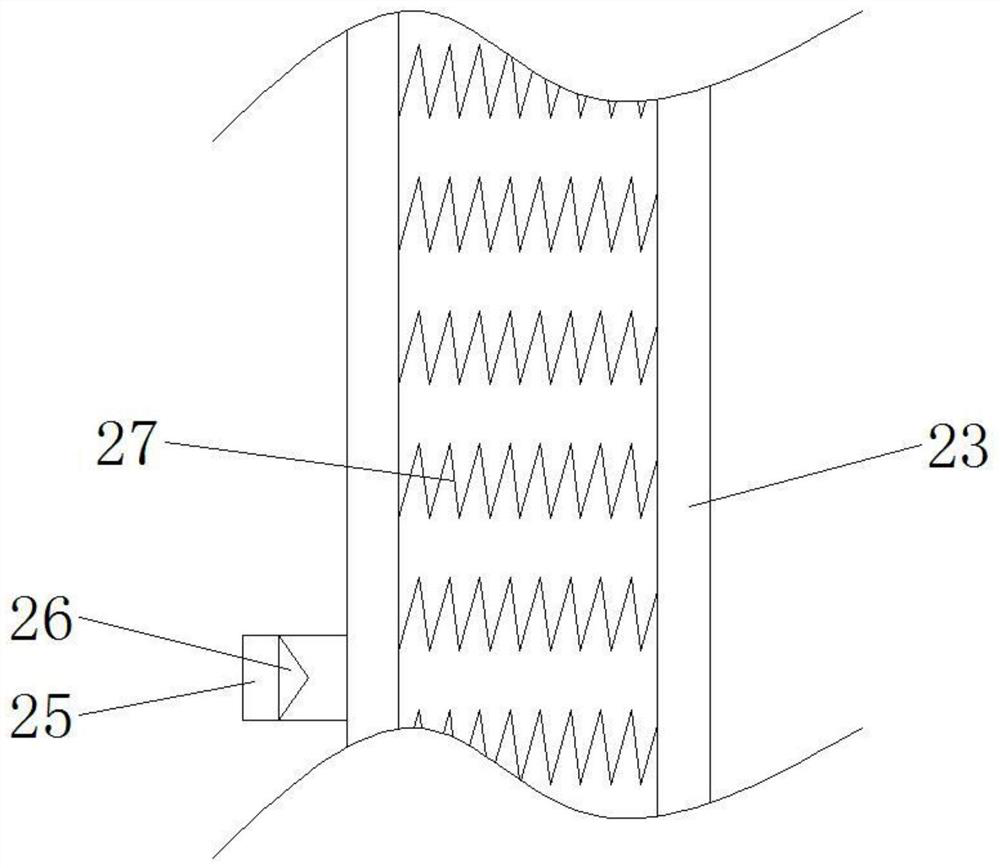

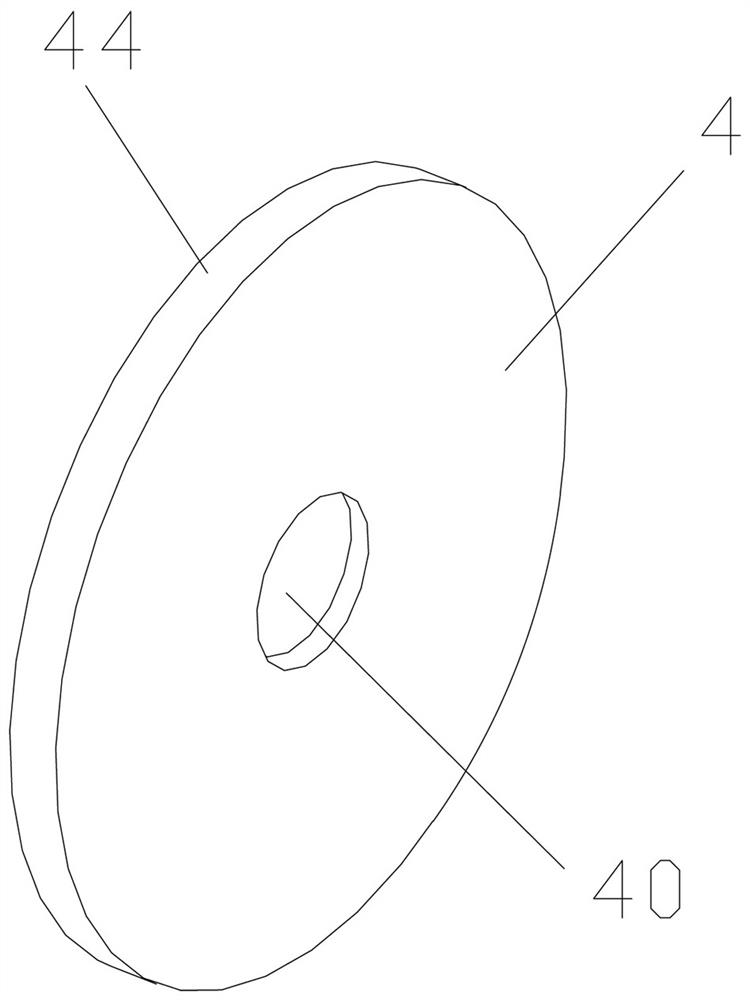

Roller used for heating, drying and continuous stirring to produce thermal regeneration mixture

InactiveCN103397589ARealize the mixing operationImprove continuityRoads maintainenceManufacturing technologyThermodynamics

The invention relates to a roller used for heating, drying and continuous stirring to produce a thermal regeneration mixture, and belongs to the fields of plant-mixed thermal regeneration mixture equipment manufacturing technology. In the roller, a fresh material drying and heating zone, a recycled material and fresh material mixing-drying-heating zone, and a regeneration mixture stirring zone are arranged from a highest part to a lowest part; inner wall (2) of the roller is provided with material stirring blades (4); the roller is provided with a combustor (8), a fresh material inlet (9) and a fresh material conveyer (10); the fresh material drying and heating zone is provided with fresh material guide plates (1); the middle part of the roller is provided with a recycled material inlet (3); the tail of the regeneration mixture stirring zone is provided with a smoke box (7), a regeneration mixture outlet (6) and an asphalt additive jet pipe (5). The roller is capable of drying and heating fresh materials and recycle materials, producing thermal regeneration mixture continuously, replacing heating and drying devices provided with two rollers, improving production technologies, and simplifying production equipment further.

Owner:郴州市三联路面机械有限责任公司

Water surface contaminant removing system for water conservancy project

InactiveCN109322293AReduced service lifeAchieve dryingWater cleaningTransportation and packagingEngineeringHydraulic engineering

The invention discloses a water surface contaminant removing system for a water conservancy project and relates to the technical field of water conservancy projects. The water surface contaminant removing system for the water conservancy project comprises a supporting frame, one surface of the supporting frame is fixedly provided with a pair of supporting plates, a first driven roller is rotationally connected between one ends of the supporting plates, a first drive roller is rotationally connected between the other ends of the supporting plates, the circumferential side face of the first drive roller and the circumferential side face of the first driven roller are in transmission connection with a fishing chain plate, and fishing claws are linearly arrayed on the circumferential side faceof the fishing chain plate. One end of the first drive roller is fixedly provided with a drying device. According to the water surface contaminant removing system for the water conservancy project, by means of the drying device, contaminants fished by the contaminant removing device are advantageously drained, dried and discharged out of a machine box, and the situation that the water on the contaminants is left in the machine box in the mashing and compressing process and cannot be discharged out in time, and consequently mechanical parts in the machine box are corroded by the residual water, the service life of the removing device is shortened, and the progress of the water conservancy project is affected is prevented.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Flue gas desulfurization tower for coal-fried boilers

ActiveCN105148716AReduce hindranceImprove desulfurization effectDispersed particle separationElectric machineryCoal

The invention discloses a flue gas desulfurization tower for coal-fried boilers. The flue gas desulfurization tower comprises a tower body, a tower top, a flue gas inlet, a flue gas outlet and the like. A discharge outlet is formed at the bottom of the tower body; the flue gas inlet is formed at the lower side of the tower body; and the flue gas outlet is formed at the tower top. A nozzle is arranged at the center position of the tower body; a separating filter plate is arranged inside the tower body at the upper end of the flue gas inlet; an electric motor is arranged at the bottom of the tower body; a scraping and stirring device is connected with the electric motor through a rotating shaft. A desulfurizer is filled in the tower body. A circulating port is arranged at a position of the tower body at the upper end of the separating filter plate, and is connected with the nozzle through a pipeline; a circulating pump is arranged on the pipeline between the circulating port and the nozzle; and a liquid level probe is mounted at the upper end of the separating filter plate. With the separating filter plate, calcium sulfate generated after reaction is separated on the lower side of the separating filter plate, so that inhibition to desulfurization caused by calcium sulfate is reduced greatly while desulfurization effect is improved greatly.

Owner:湖北省南峰节能服务有限公司

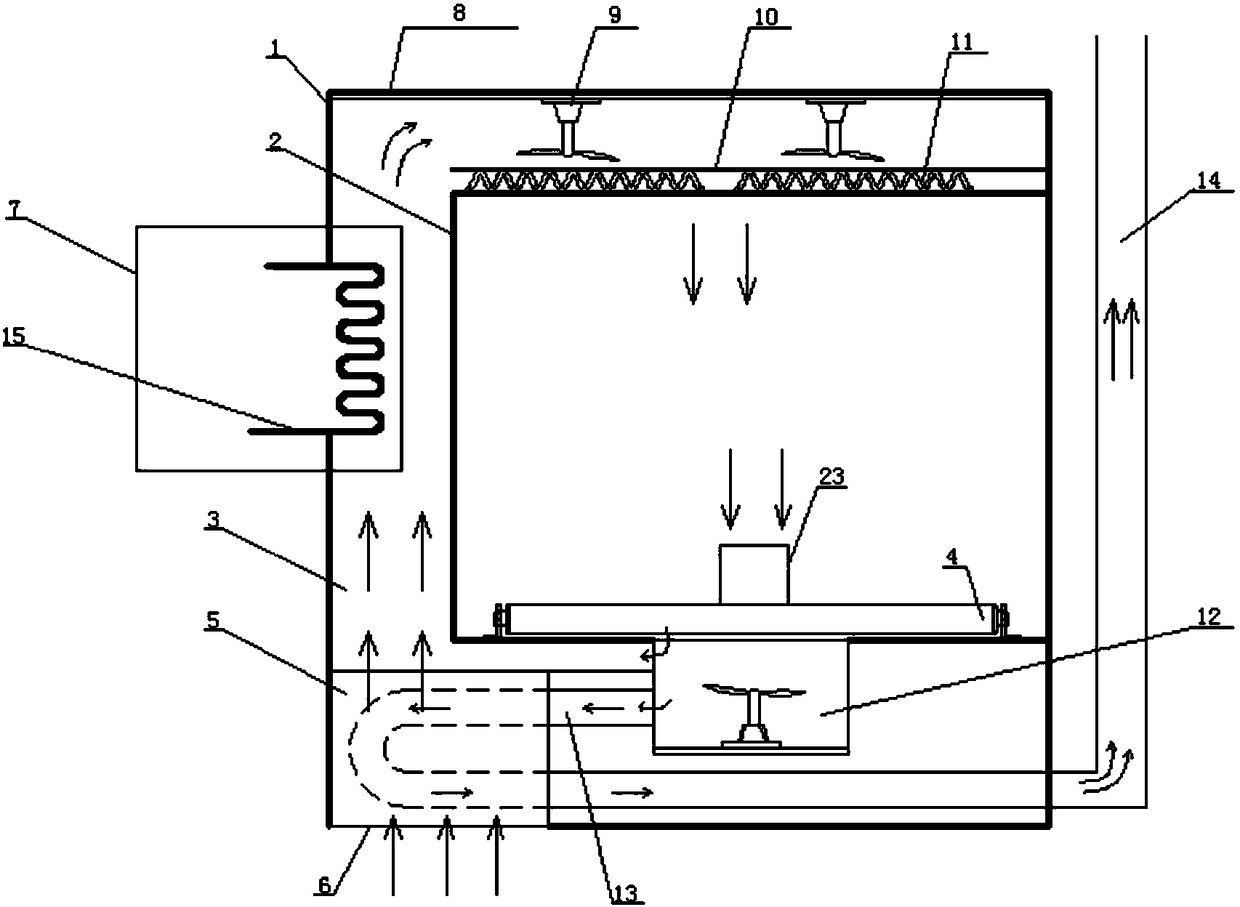

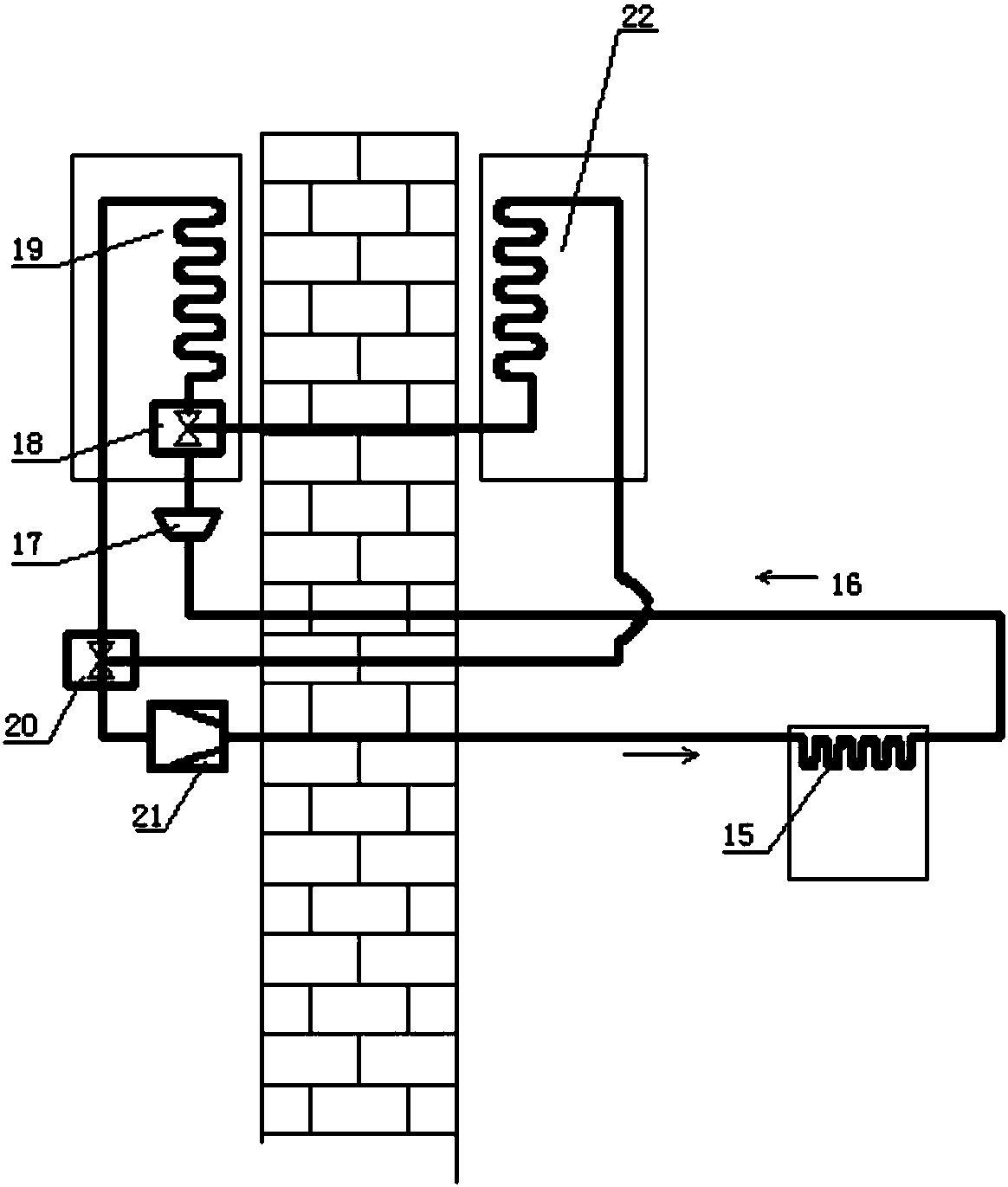

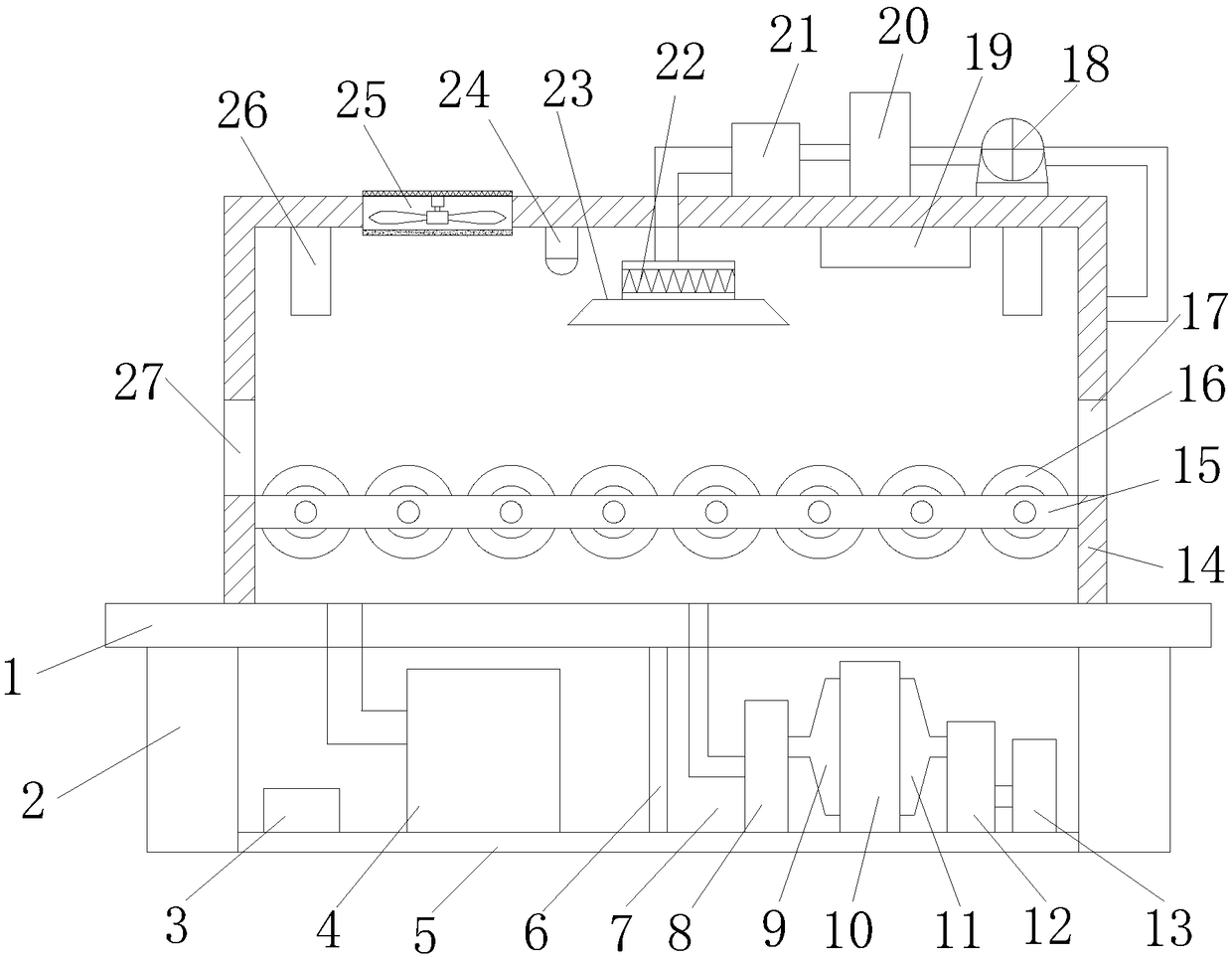

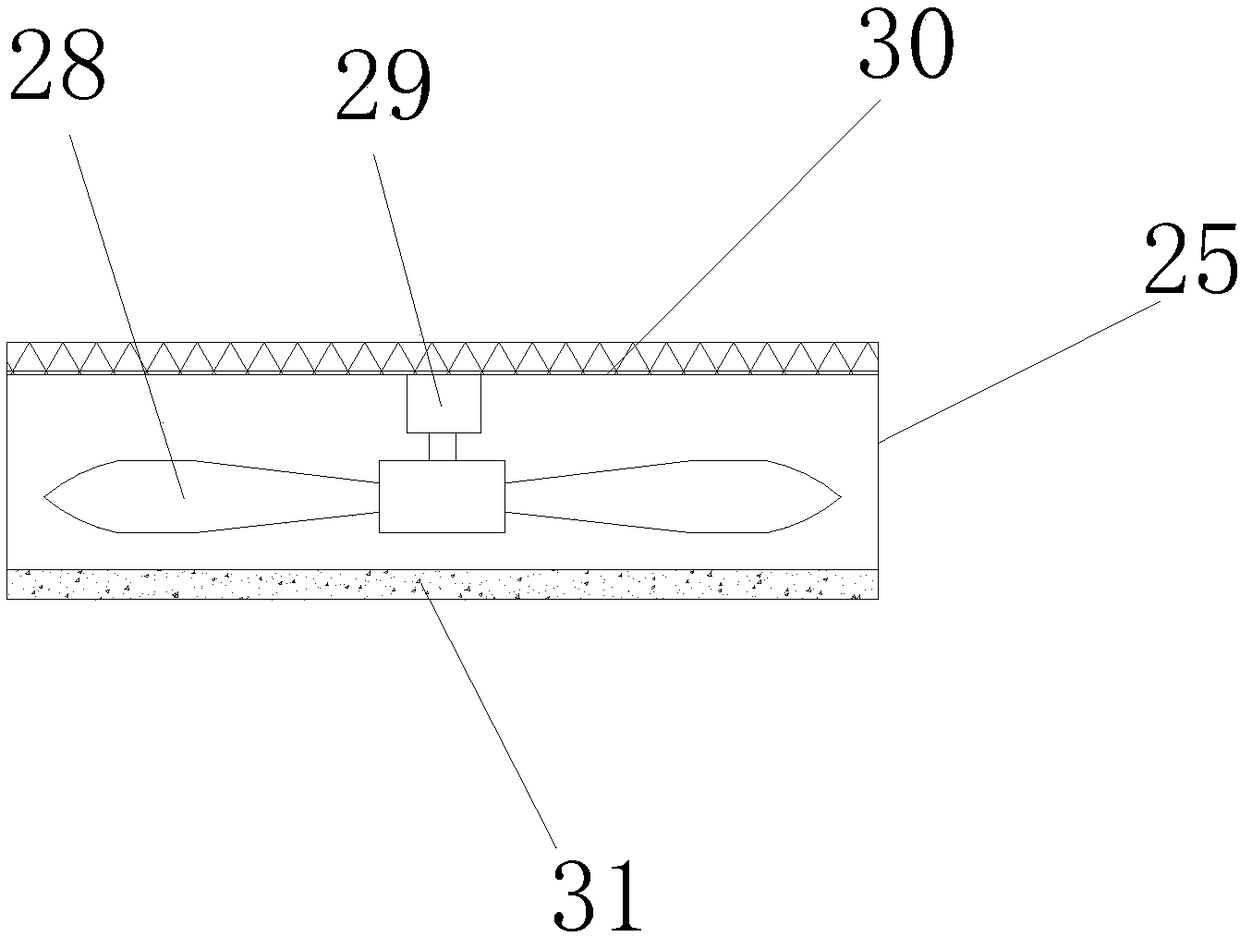

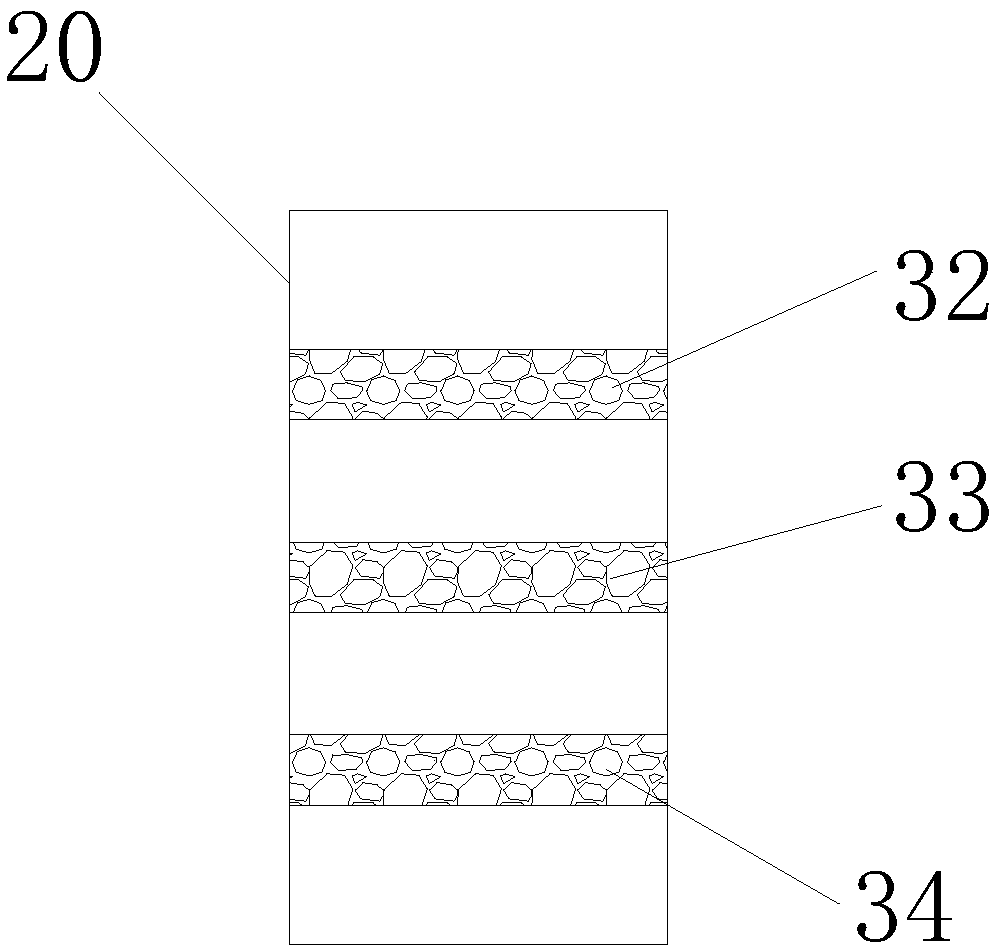

Energy-saving tunnel drying oven

ActiveCN108131930AHeating evenlyFully heatedDrying gas arrangementsDrying chambers/containersWorking environmentEngineering

The invention relates to an energy-saving tunnel drying oven. The energy-saving tunnel drying oven comprises an outer shell, an inner shell, an air channel, a conveyor belt, a heat exchanger, an air inlet, a heat pump system, fans, heating devices, an air flow distributor, an air exhaust pipe and the like. Outside air enters the air channel through the air inlet, the air is preheated by the heat exchanger, heated by the heat pump system and subjected to auxiliary constant temperature keeping by the heating devices, and the air heats and dries heated objects on the conveyor belt; and through distributing of the air flow distributor, the part of hot air is subjected to heat exchanging by the heat exchanger and then exhausted through the air exhaust pipe, and the other part of hot air is mixed with new air preheated by the heat exchanger, heated by the heat pump system and heated by the heating devices, then heats and dries the heated objects, and is distributed by the air flow distributor, in this way, heat energy in the air is circularly utilized, the energy is saved, and the heating efficiency is improved. When the working environment temperature is high, the heat pump system can further be used for cooling the working environment while being used for heating the air.

Owner:GUANGZHOU HENGXINCHUANGZHAN TECH CO LTD

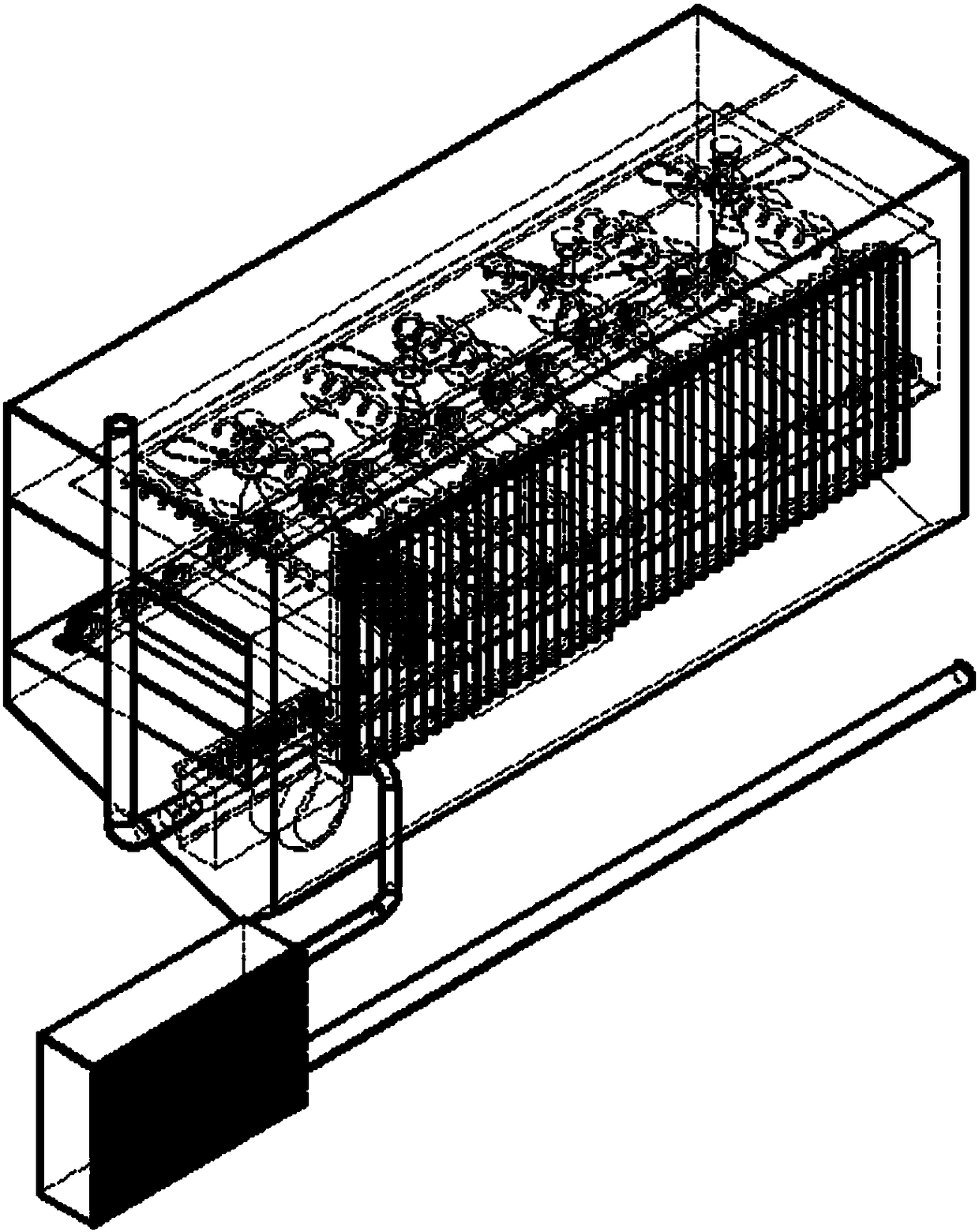

Novel aquaculture feed mixing device convenient to move

InactiveCN108579507AEasy to sendImprove mixing efficiencyFeeding-stuffTransportation and packagingElectricityEngineering

The invention provides a novel aquaculture feed mixing device convenient to move. The feed mixing device comprises a feed inlet hopper, a protective cover, a stirring mixing device, a drying heat-insulating shell structure, a temperature-humidity sensor, a feed guide frame, a slot, a partition plate, a trapezoidal rubber block, a handle, a feed guide plate and an adjustable bottom wheel structure,wherein a bolt of the feed inlet hopper is installed at the upper left part of the stirring mixing device. Through arrangement of spiral auger blades, upward conveying of the aquaculture feed is conducted conveniently, and by further combining arrangement of stirring blades, the efficiency of stirring and mixing is improved; through arrangement of a temperature controller and an electric heatingwire, improvement of a heating drying effect on the aquaculture feed in a stirring outer frame is facilitated, so that the aquaculture feed in the stirring outer frame is prevented from being exposedto moisture and damaged; through arrangement of threads of a thread rod and an adjusting nut, adjustment of the connected length of the thread rod to the outer side of the adjusting nut in an insertedmode can be facilitated according to use requirements, and by combining arrangement of universal bottom wheels, movement of the feed mixing device can be facilitated when movement is needed.

Owner:LIUZHOU WENHUA BREEDING FARM

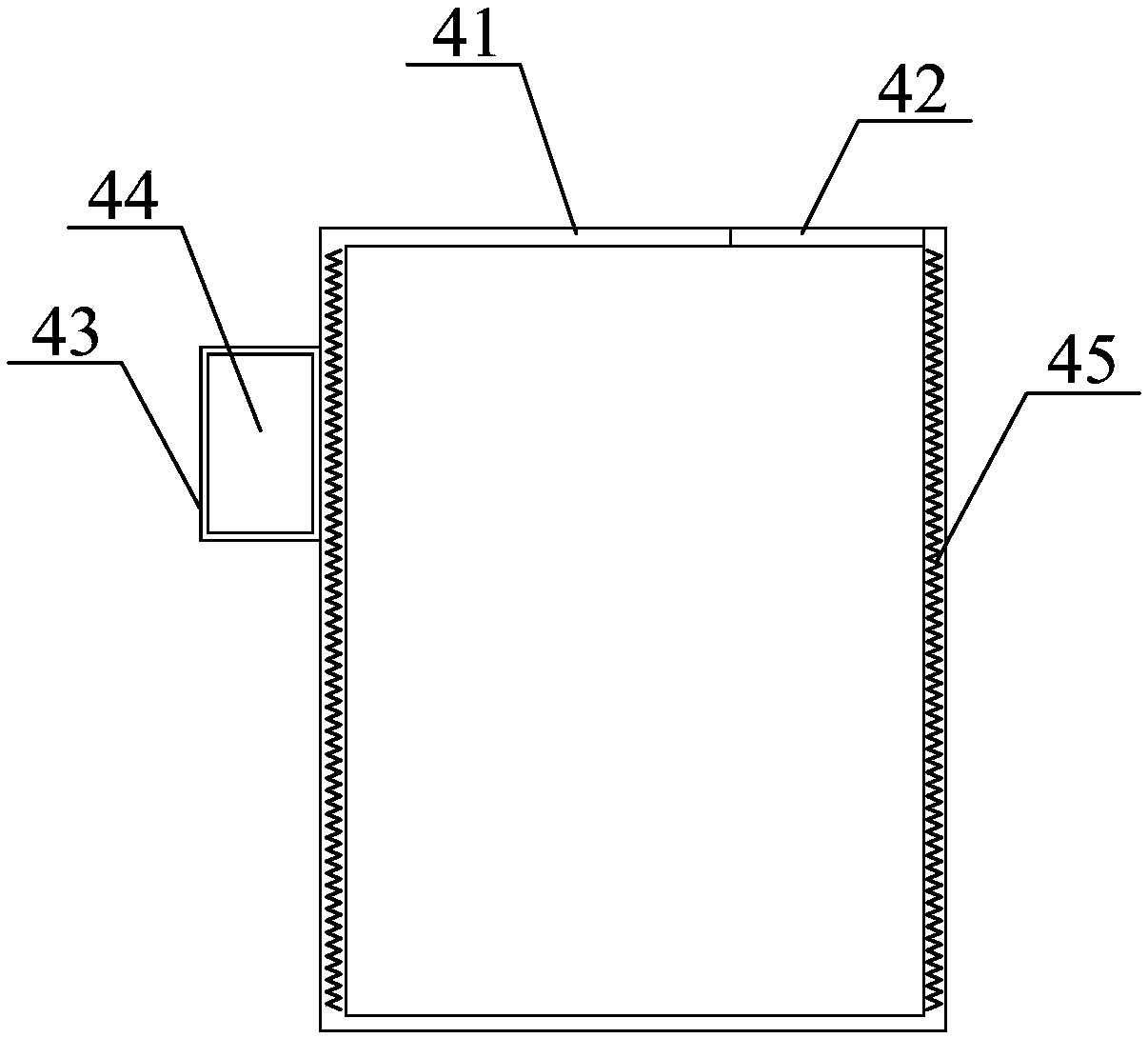

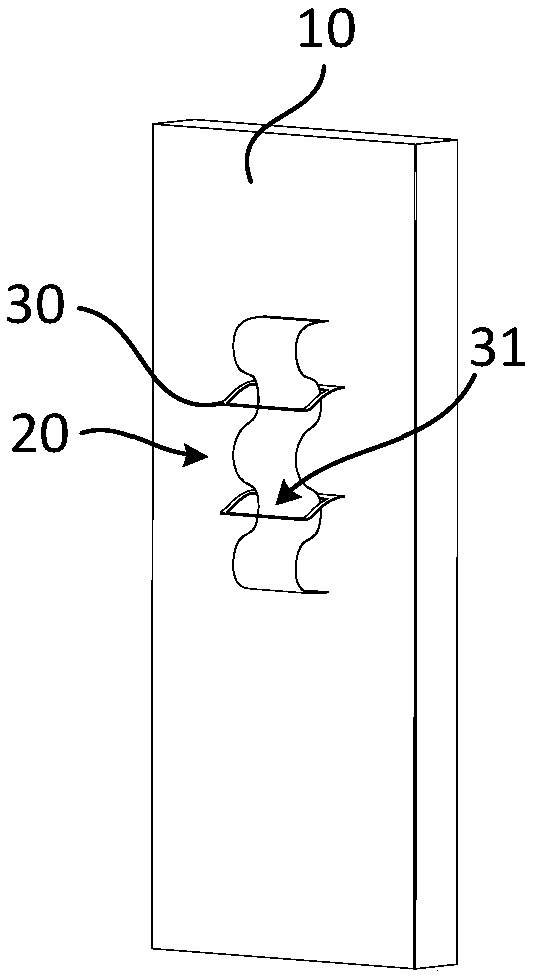

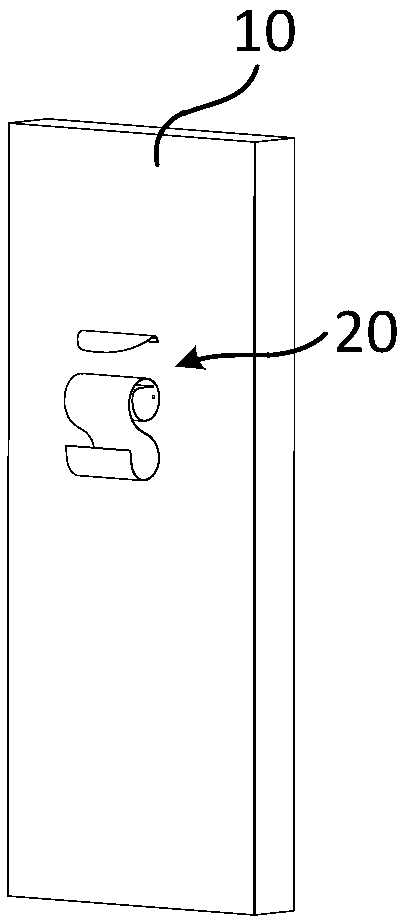

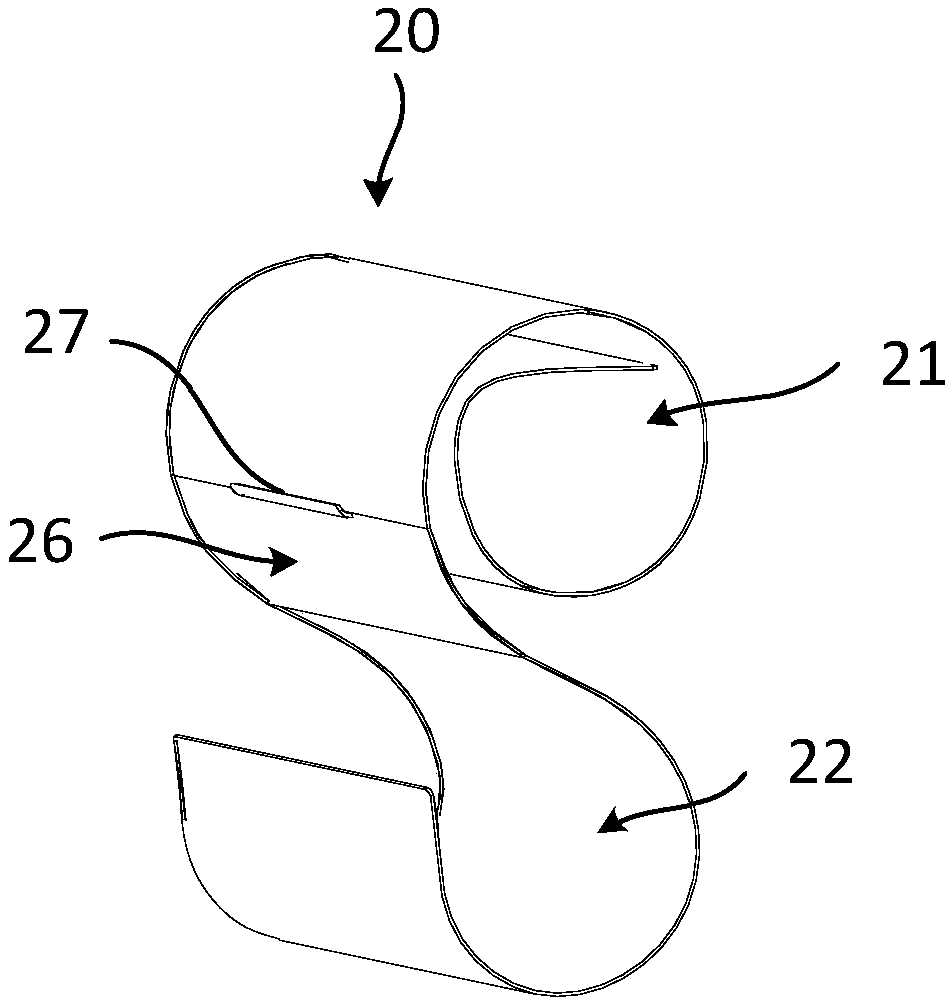

Material storage device for pipe color master batch production

InactiveCN112918924AEffective protectionPrevent leakageContainers preventing decayReaction layerWater vapor

The invention discloses a material storage device for pipe color master batch production, and belongs to the technical field of color master batches. Water in a color master batch storage space can be absorbed through water absorption vertical wires, and the water is conveyed into movable balls and then flows to water collection pieces through migration pieces; after the water is accumulated in the water collection pieces to a certain degree, the water-meeting shrinkage action of water-absorbing shrinkage chains is triggered, then the water-absorbing shrinkage chains pull the water collection pieces to be gradually close to the inner walls of the movable balls until the movable balls are closed, at the moment, the water-absorbing shrinkage chains also pull blocking balls to open the water collection pieces, and water accumulated on the water collection pieces flows down to a reaction layer; then reaction is carried out to generate a large amount of gas, the gas is firstly accumulated in the movable balls until air blowing films are inflated and expanded to increase the overall buoyancy of the movable balls to float, then the gas with heat is sprayed out of the movable balls and reversely enters the color master batches to perform heating and drying, water vapor and oxygen are discharged, and therefore, the color master batches are efficiently protected.

Owner:湖南省升阳新材料有限公司

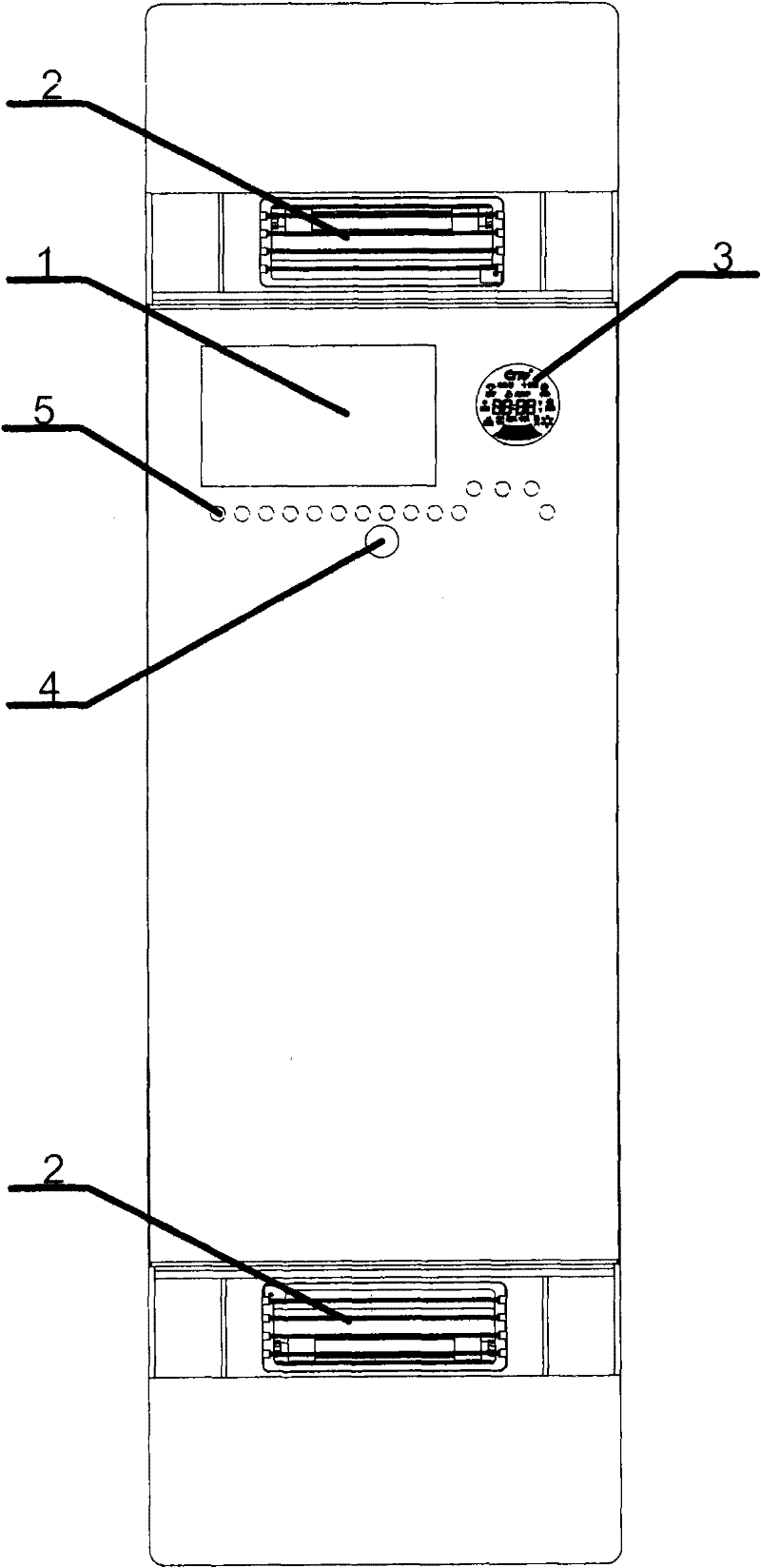

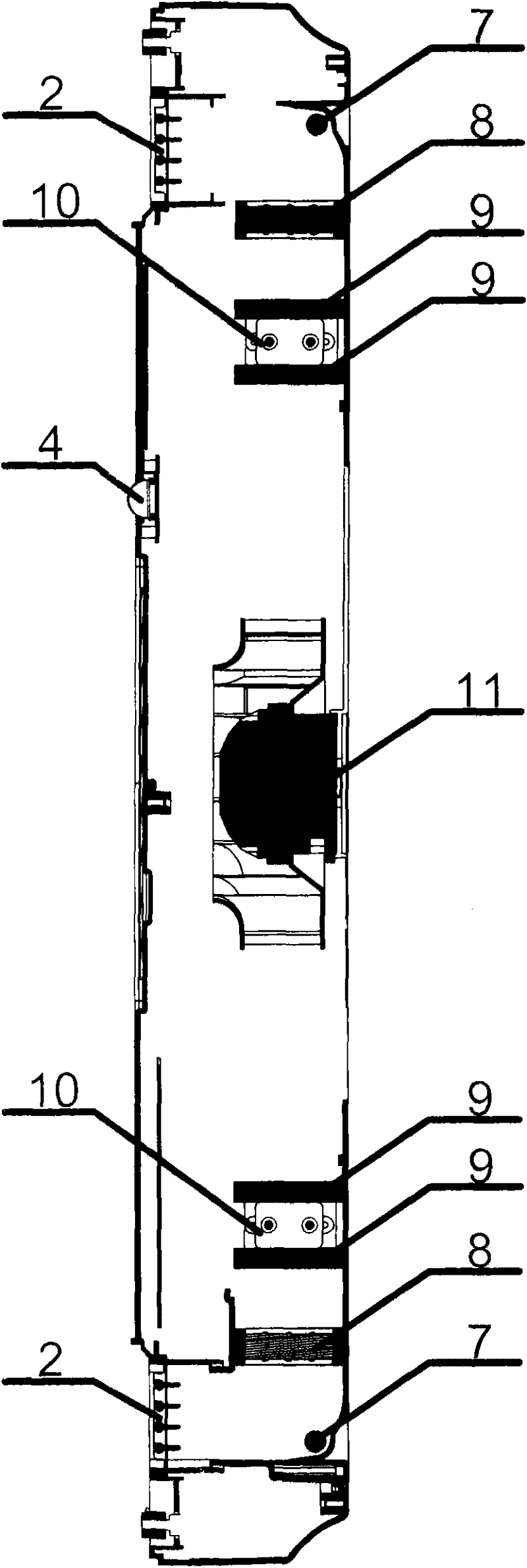

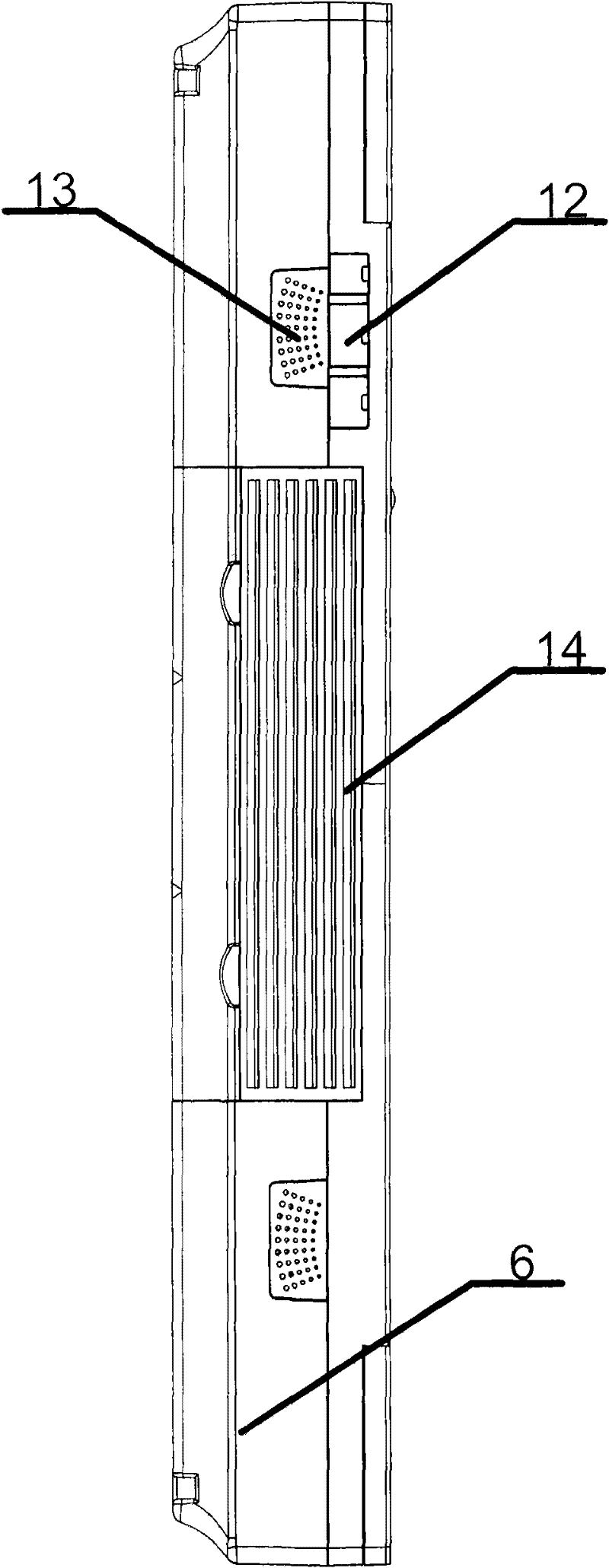

Human body drying machine

InactiveCN101744557AAvoid cross infectionHas a therapeutic effectDeodrantsDomestic applicationsHuman bodyIndoor air quality

The invention relates to a human body drying machine which comprises a vertical box body, a fan, PTC heaters, a display screen, an air inlet and an air outlet. Two nanometer titanium dioxide filter screens are respectively mounted above and under the fan in the vertical box body; an ultraviolet ray lamp tube is mounted in the middle of every two nanometer titanium dioxide filter screens; the PTC heaters are respectively mounted above the nanometer titanium dioxide filter screen at the uppermost part and under the nanometer titanium dioxide filter screen at the lowermost part; heat release inductors are mounted on the outer sides of the PTC heaters and face toward the air outlet; and the air inlet is also formed on the vertical tank body. A far infrared receiver, a functional display screen and a touch and operation key are mounted on a faceplate of the vertical box body. The display screen adopts MP4 or DVD and is provided with a USB / SD interface. The fan is a turbine fan. The invention can effectively improve the indoor air quality and facilitate the fitness.

Owner:韩春花

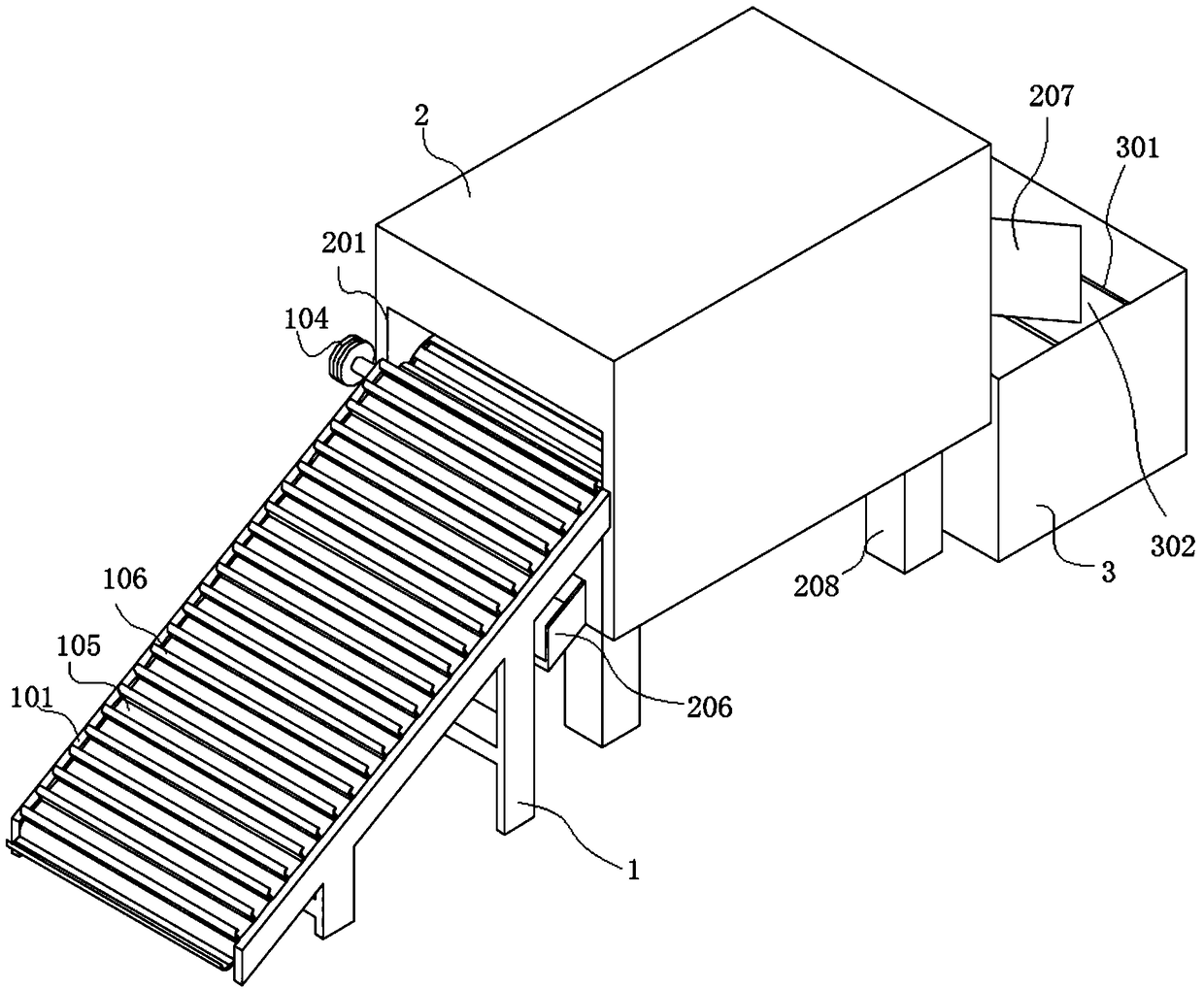

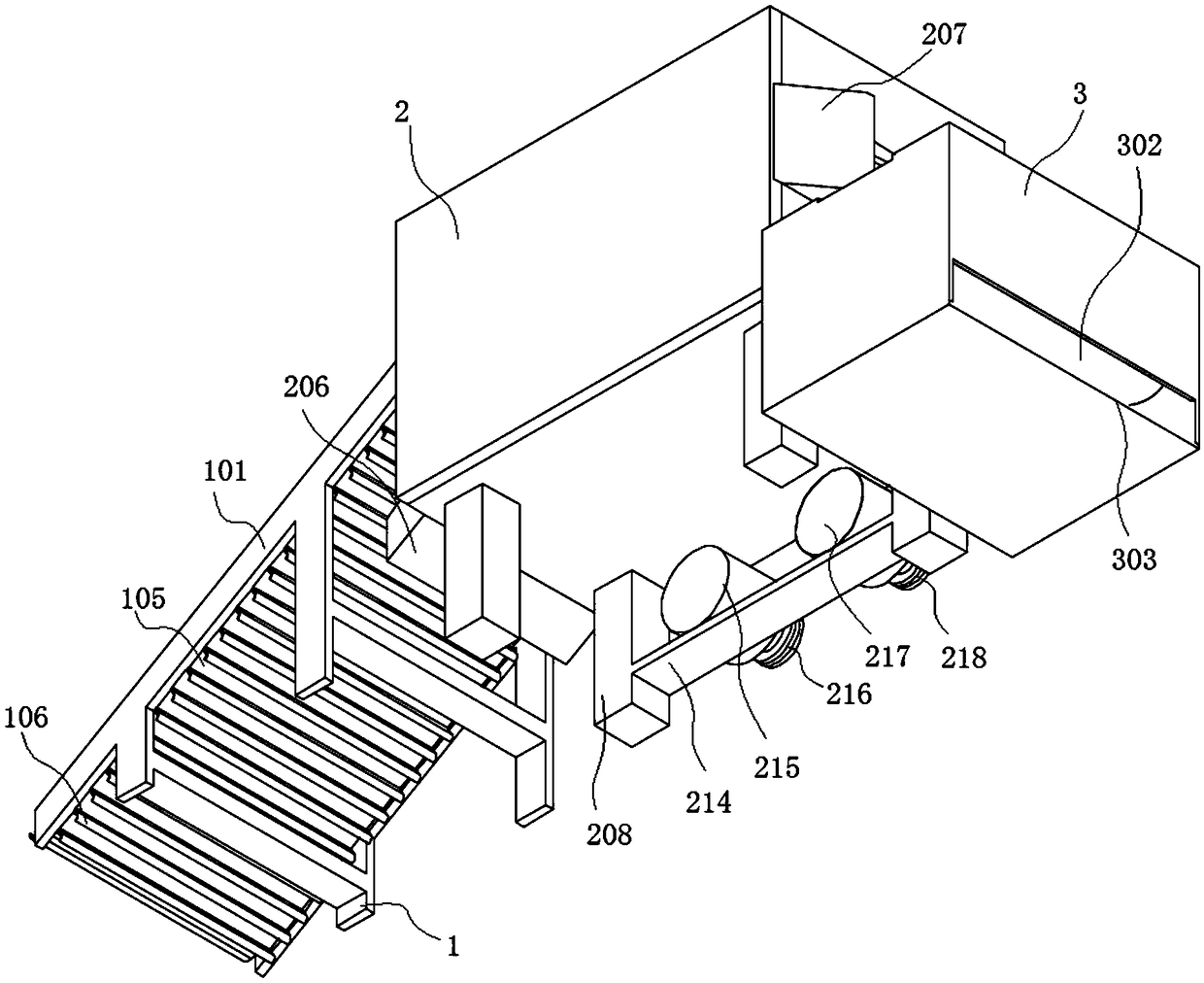

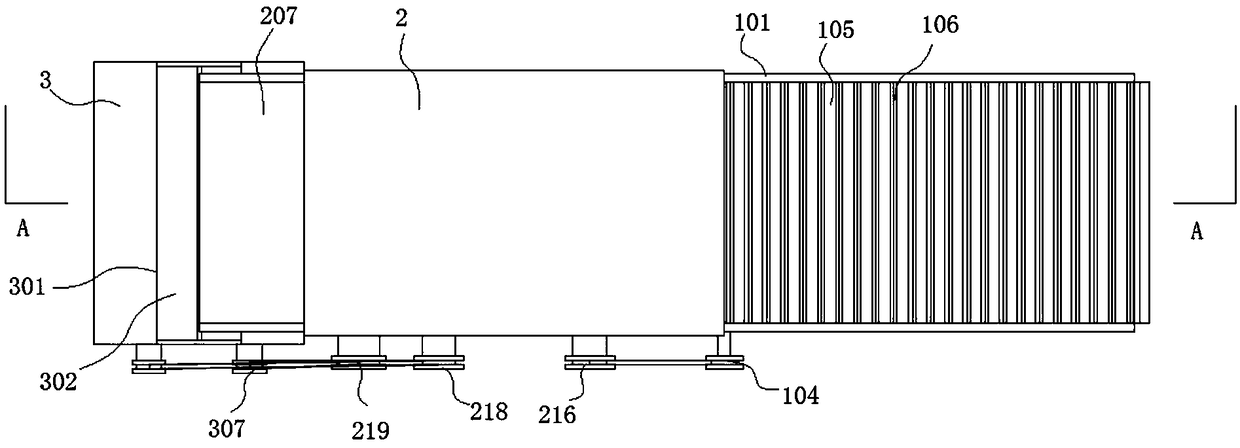

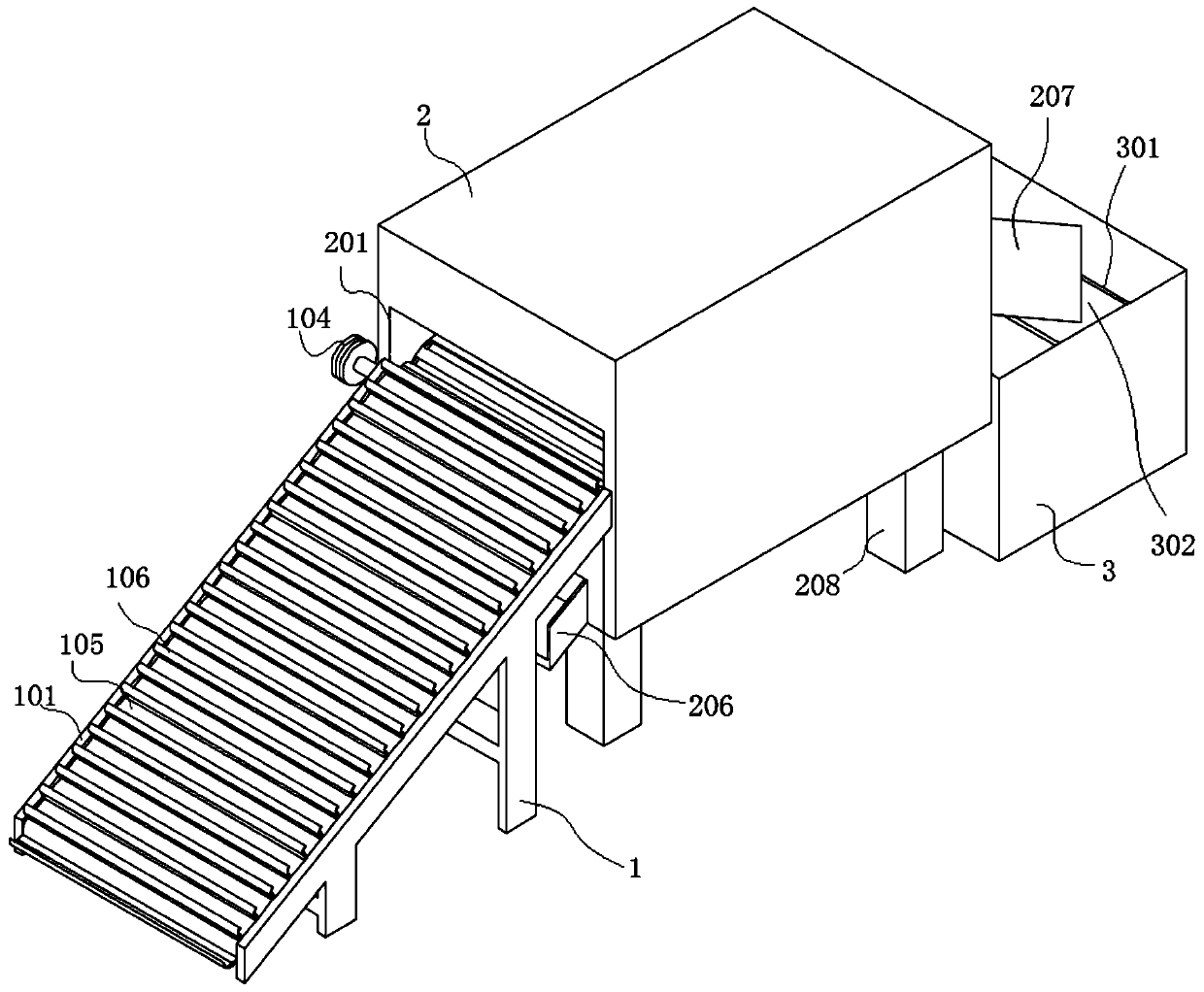

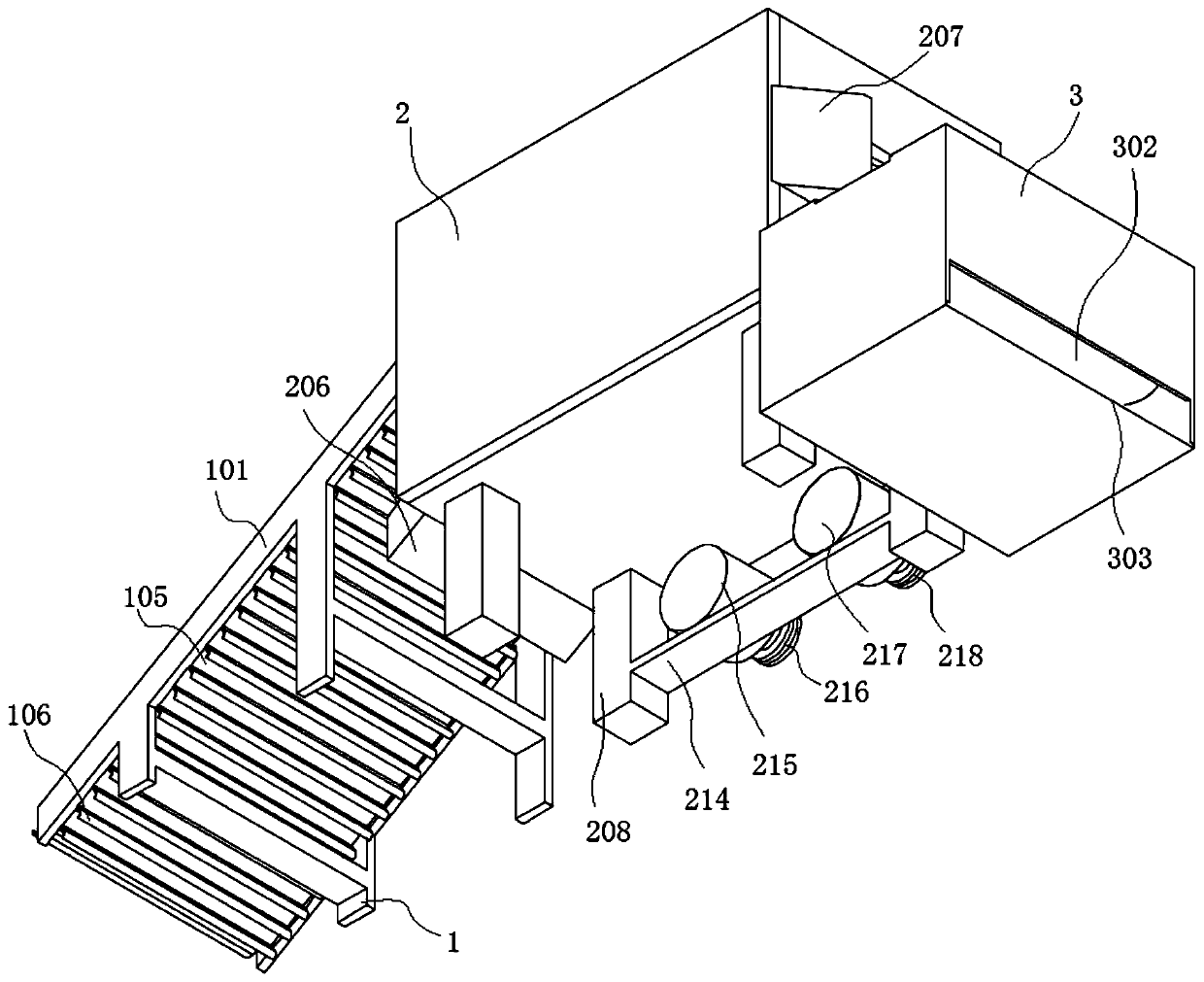

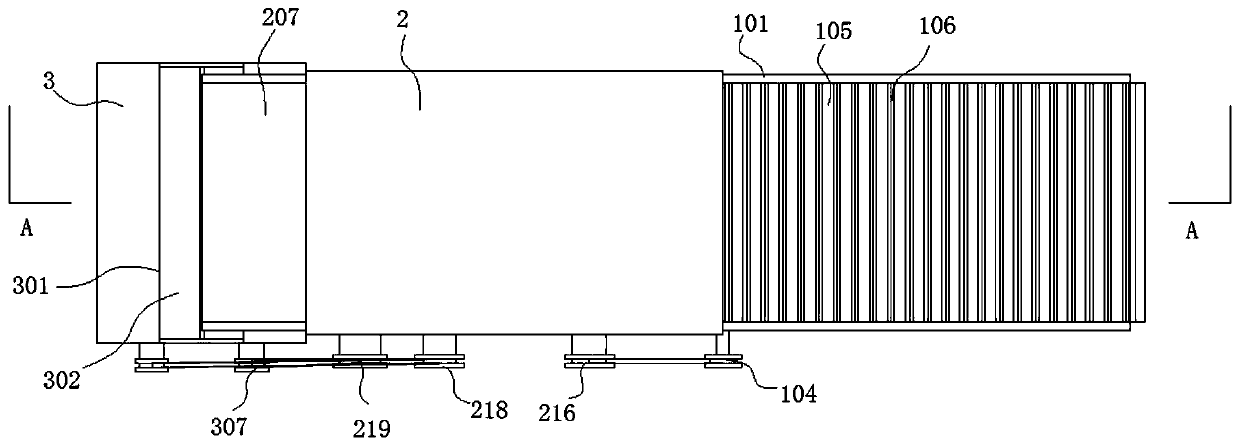

Drying device for wood-plastic floors

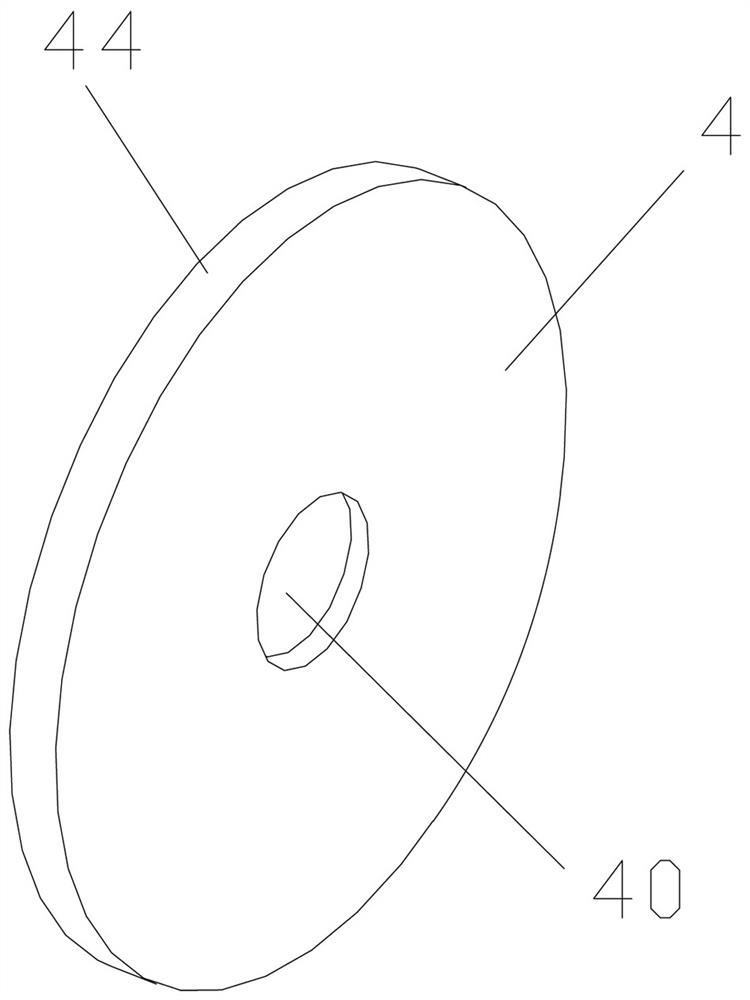

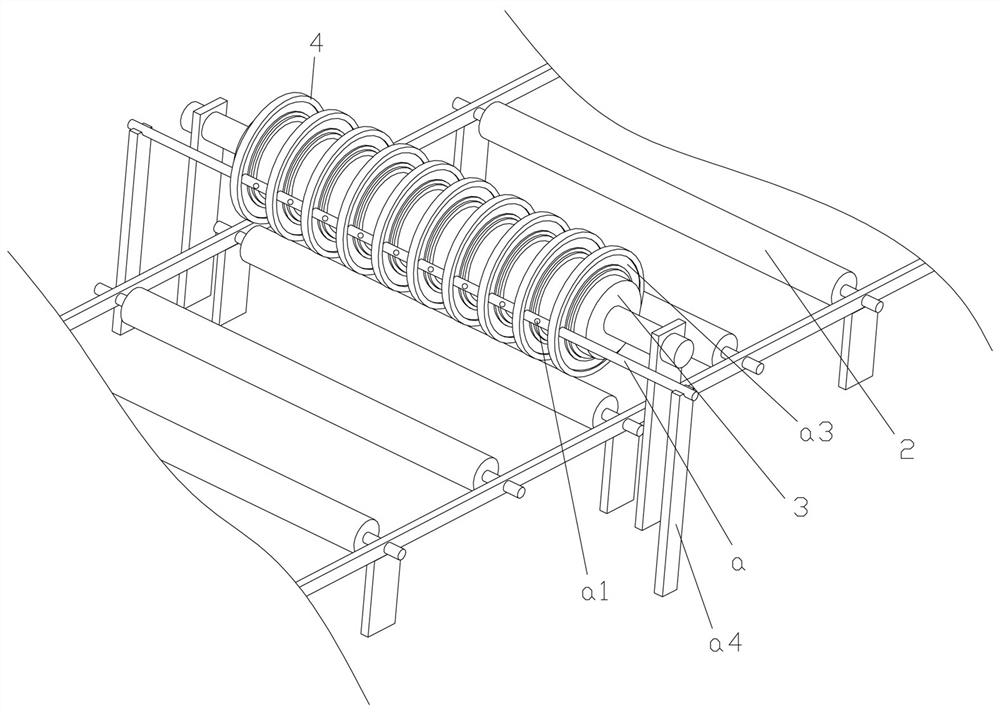

ActiveCN112414078AGood heating and drying effectImprove heating and drying effectDrying machines with progressive movementsDrying solid materialsMechanical engineeringPulp and paper industry

The invention relates to the technical field of wood-plastic floor production, in particular to a drying device for wood-plastic floors. The drying device comprises a machine frame, a conveying tableinstalled on the machine frame and used for conveying the wood-plastic floors, and a heating body extending in the left-right direction and arranged above the conveying table. The outer wall of the heating body is sleeved with a plurality of heat dissipation drying sleeve blocks which are distributed in the left-right direction of the heating body at intervals and used for being close to the uppersurface, and the heating and drying effect is good.

Owner:浙江天博生物新材料股份有限公司

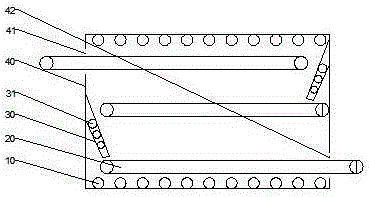

Feed dryer

InactiveCN105222552AImprove the heating effectImprove heating efficiencyDrying machines with progressive movementsDrying solid materialsHeat transmissionEngineering

The invention discloses a feed dryer. According to the scheme, the feed dryer comprises a box body and horizontal conveyor belts, wherein a feeding hole is formed in the upper part of the box body; a discharge hole is formed in the lower part of the box body; a plurality of layers of parallel conveyor belts are positioned inside the box body; one end of the uppermost layer of conveyor belt extends into the feeding hole; one end of the bottommost layer of conveyor belt extends out of the discharge hole; baffle plates are arranged between the discharge ends of the conveyor belts and the feeding ends of the lower layers of conveyor belts; the baffle plates are arranged on the box body in an inclined mode; heating tubes are arranged in the baffle plates; and heat tubes are arranged on the top surface and the bottom surface of the inner wall of the box body. The invention aims to provide the feed dryer which solves the problems of low heat transmission efficiency and longer drying time due to the fact that materials are not in direct contact with a heat source in the prior art.

Owner:CHONGQING UNION MACHINE MFG

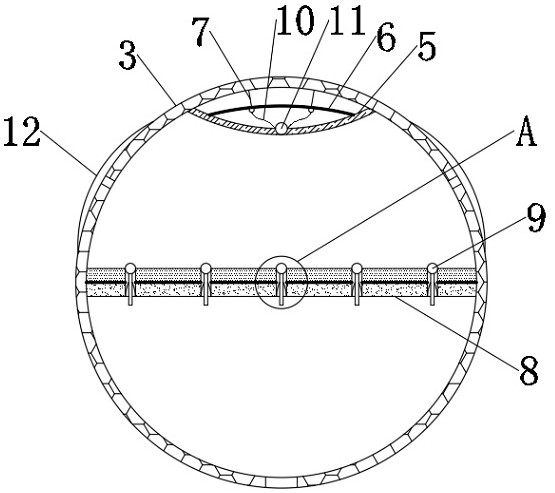

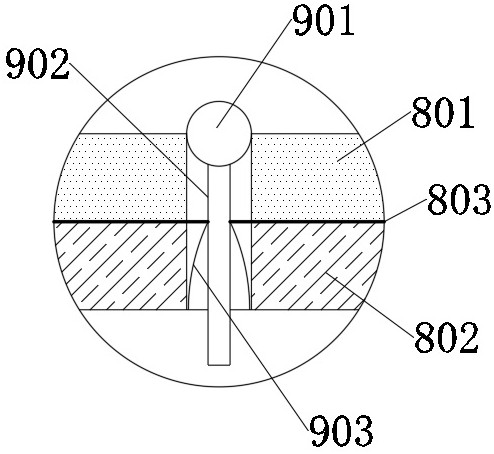

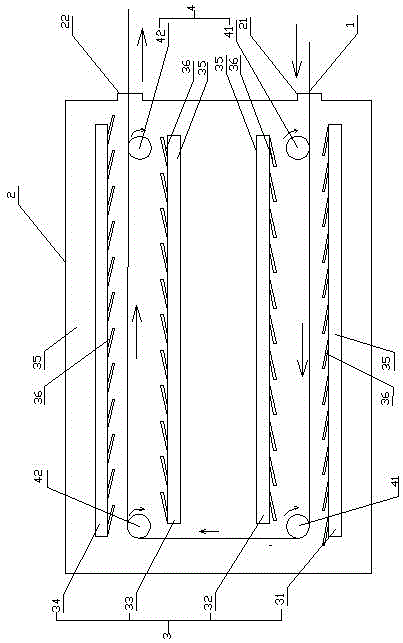

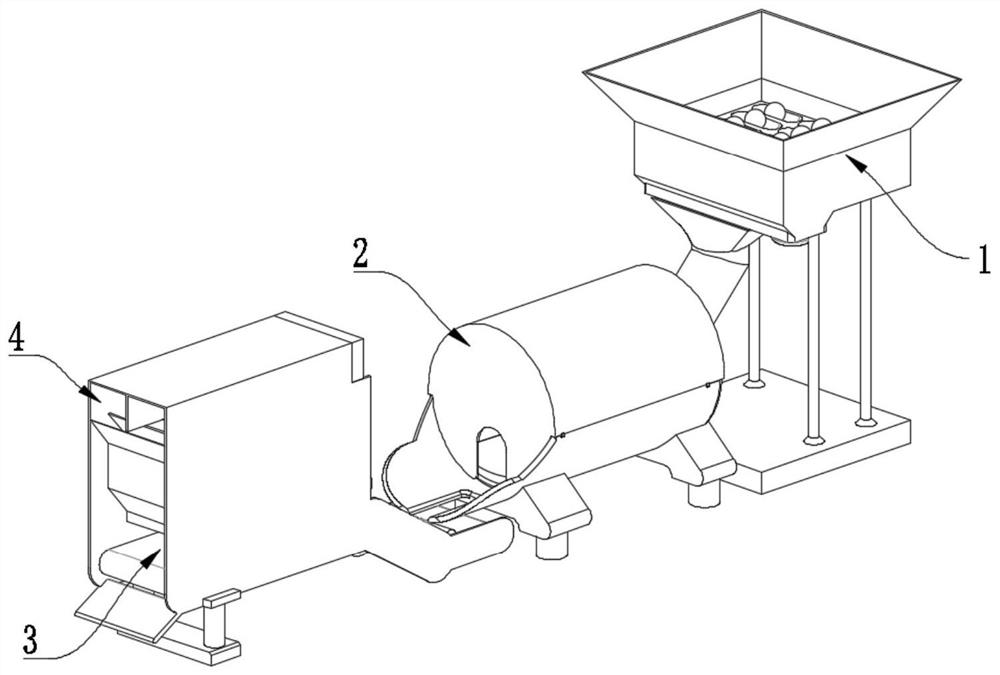

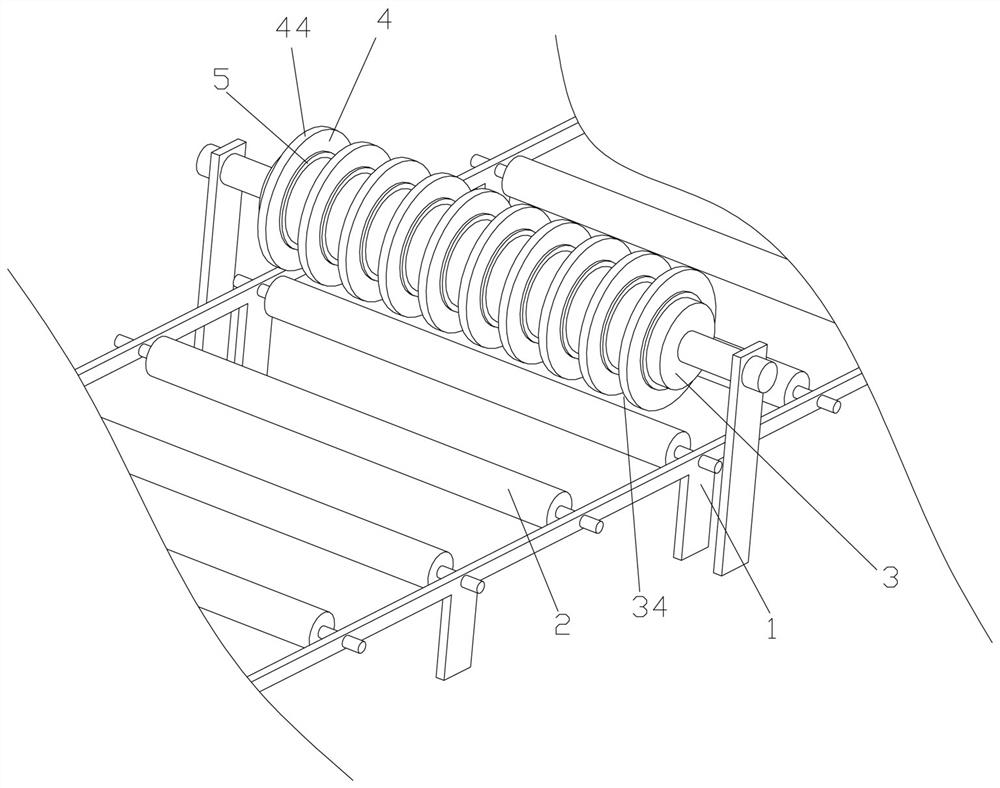

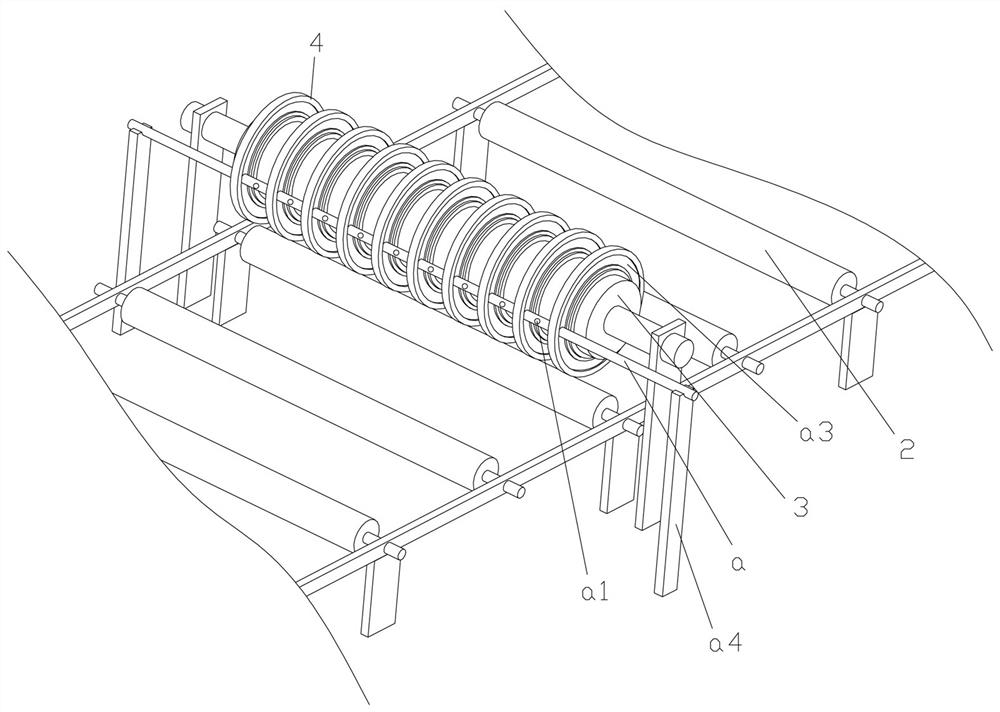

Roller capable of simultaneously drying and heating reclaimed material and new aggregate

InactiveCN103321126APrevent agingScientific and reasonable structure designRoads maintainenceEngineeringAsphalt

The invention relates to a roller capable of simultaneously drying and heating a reclaimed material and new aggregate, which belongs to the technical field of manufacturing of hot mix plant recycling equipment for a mixture. The roller capable of simultaneously drying and heating the reclaimed material and the new aggregate comprises a roller (1). The end face of one end of the roller (1) is provided with a combustor (2), and the tip of the other end of the roller (1) is provided with a smoke box (3); two drying and heating areas are sequentially arranged in the section of the roller (1) located between the combustor (2) and the smoke box (3), and material reversing blades (6) are covered on the inner walls of the drying and heating areas; the roller (1) is provided with a new aggregate inlet (7), a new aggregate outlet (8), a reclaimed material inlet (9) and a reclaimed material outlet (10); and a material guiding cone (11) and a material blocking cone (12) are arranged on a boundary cross section of the two drying and heating areas. According to the invention, one roller is used for simultaneous drying and heating of the reclaimed material and the new aggregate to replace heating and drying through two rollers, so ageing of asphalt in the reclaimed material is prevented, process is simplified, and manufacturing cost for equipment is reduced.

Owner:郴州市三联路面机械有限责任公司

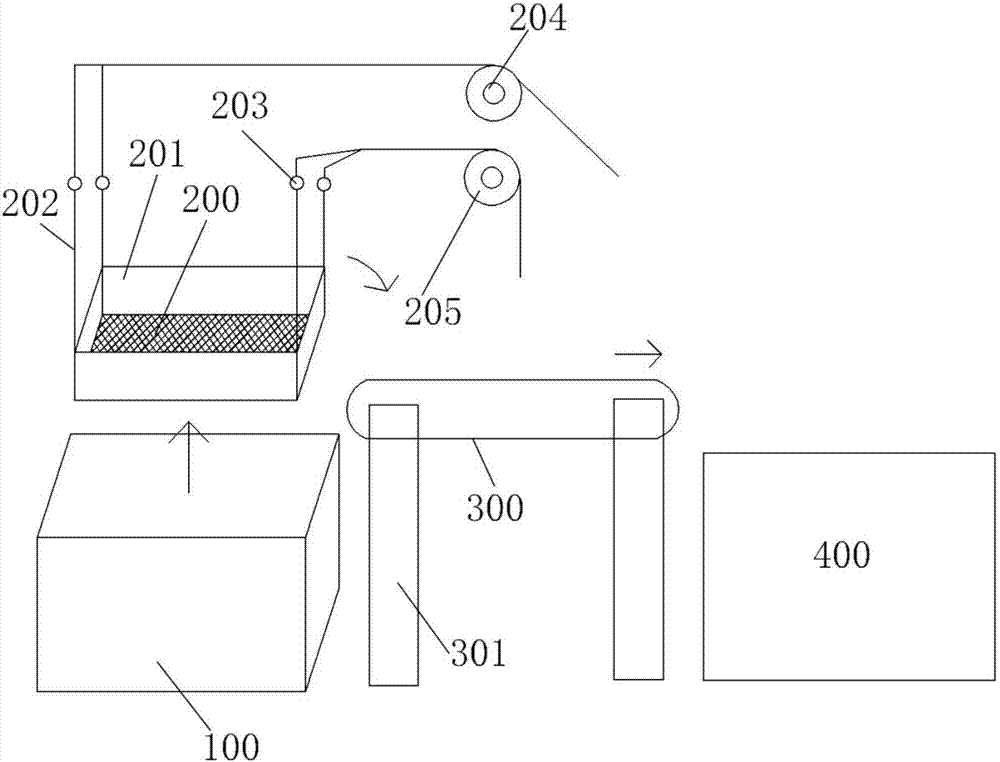

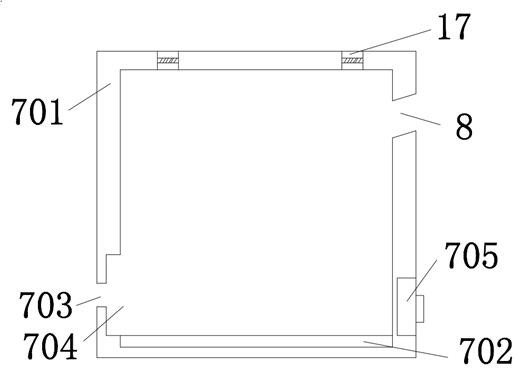

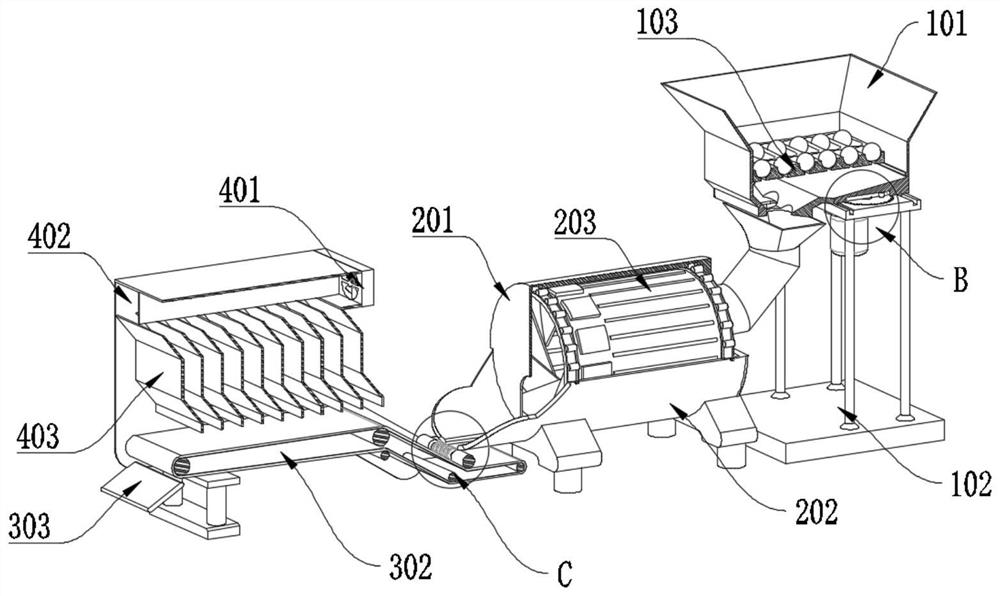

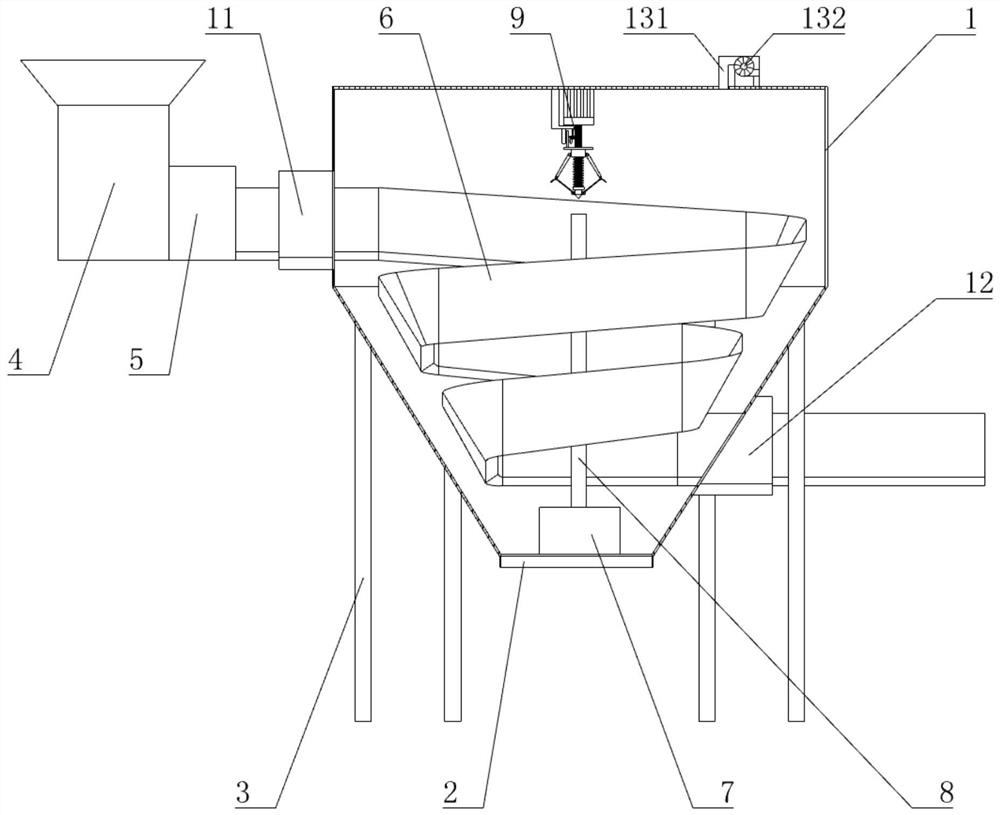

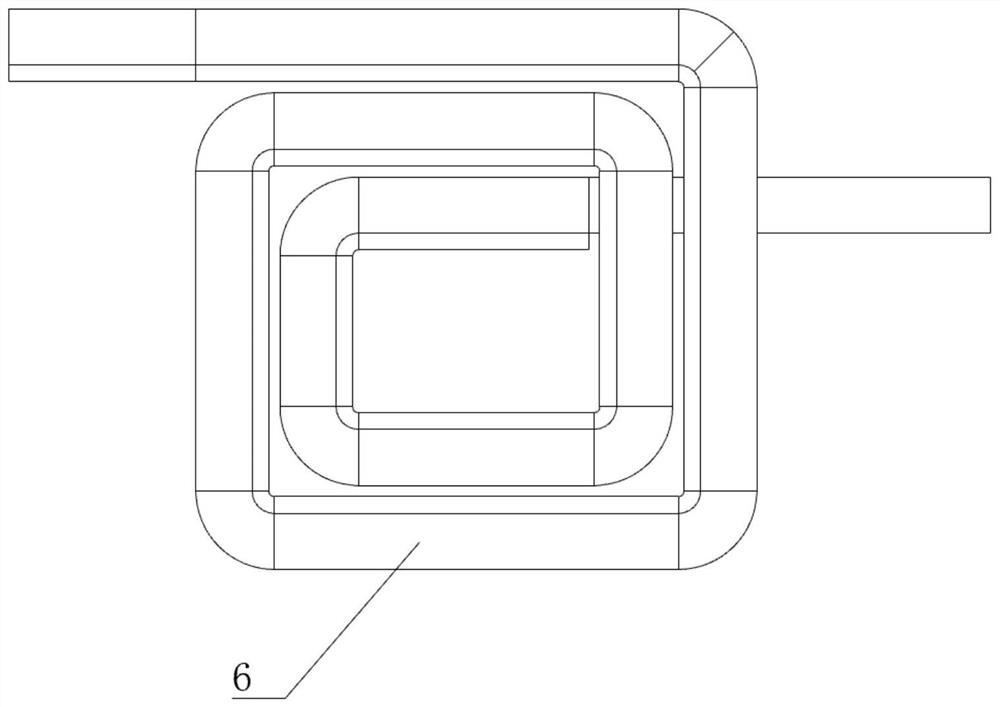

Non-polluting environment-friendly feed system

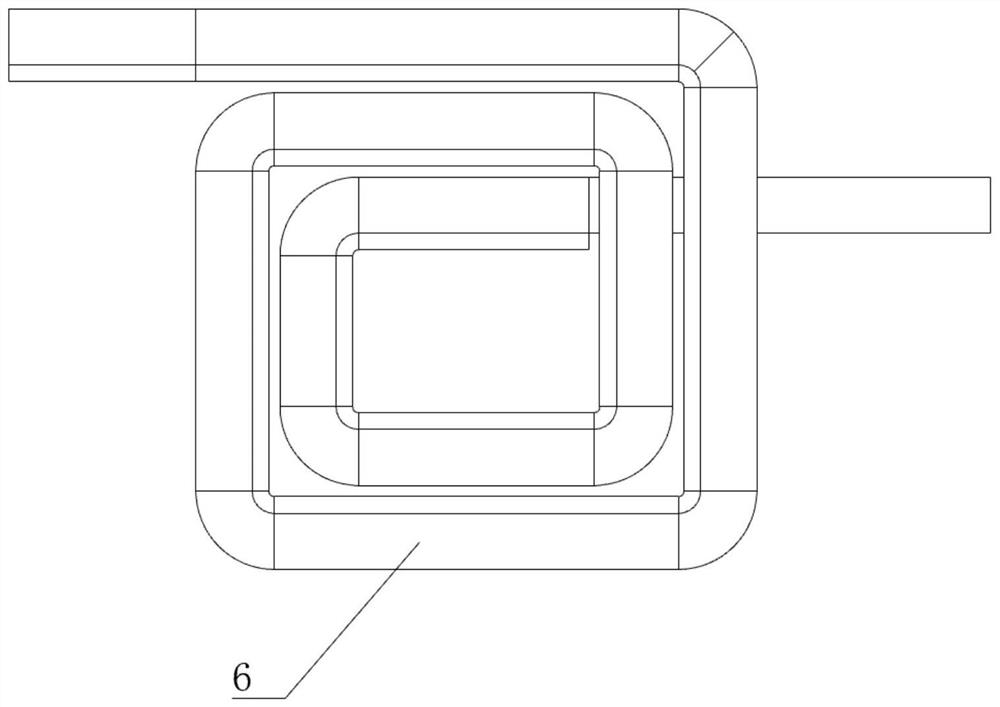

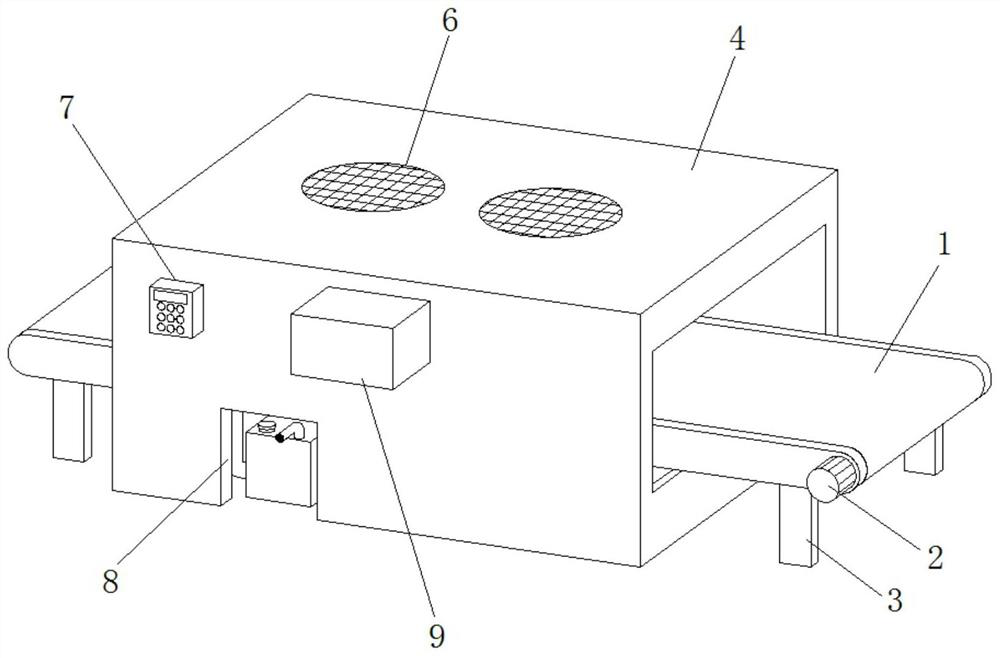

Provided is a non-polluting environment-friendly feed system. The feed system is characterized by comprising a fermentation tank, a filter net, a conveyor belt and a heating and drying device. The square filter net is provided with four side plates in a protruding mode, the four corners of the side plates are connected with rings through steel wires, the two rings on the left side are wound on a first pulley through a common steel wire, and the two rings on the right side are wound on a second pulley through a common steel wire. The conveyor belt stands on the right side of the fermentation tank through supporting frames, and the heating and drying device is located on the right side of the conveyor belt.

Owner:江苏佳谷生物科技有限公司

Pickling sludge dewatering device

ActiveCN112759224AImprove uniformityReduce occupancySludge treatmentWaste water treatment from metallurgical processWaveguideMechanical engineering

The invention discloses a pickling sludge dewatering device, and the device comprises a dewatering chamber; a main body of the dewatering chamber is in an inverted pyramid frustum shape, a spiral conveying belt matched with the inner wall of the dewatering chamber is arranged in an inner cavity of the dewatering chamber from top to bottom, a magnetron is arranged in the center of the bottom of the inner cavity of the dewatering chamber, a vertical waveguide tube is connected to the upper portion of the magnetron, a microwave stirrer fixed to the top of an inner cavity of the dewatering chamber is arranged over the output end of the waveguide tube, the input end and the output end of the conveying belt penetrate through a feeding port and a discharging port of the dewatering chamber respectively, and the bearing face of the conveying belt is obliquely arranged and faces the waveguide tube and the microwave stirrer. The pickling sludge is dewatered in a microwave heating mode, the sludge plate absorbs microwave energy, so the temperature is continuously increased;meanwhile, water in the sludge plate is evaporated, the dewatering effect is achieved, and environmental pollution and land occupation are reduced.

Owner:江苏亿洲再生资源科技有限公司

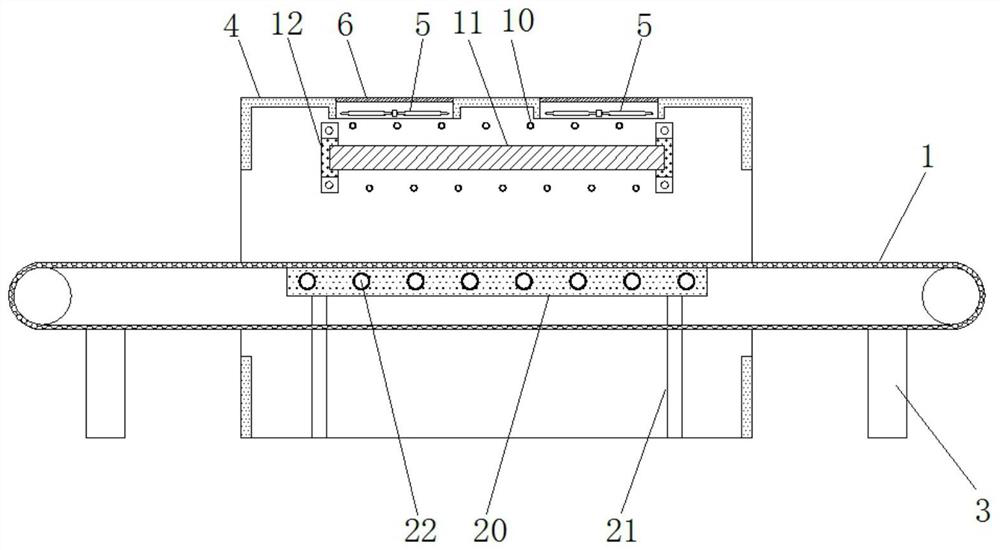

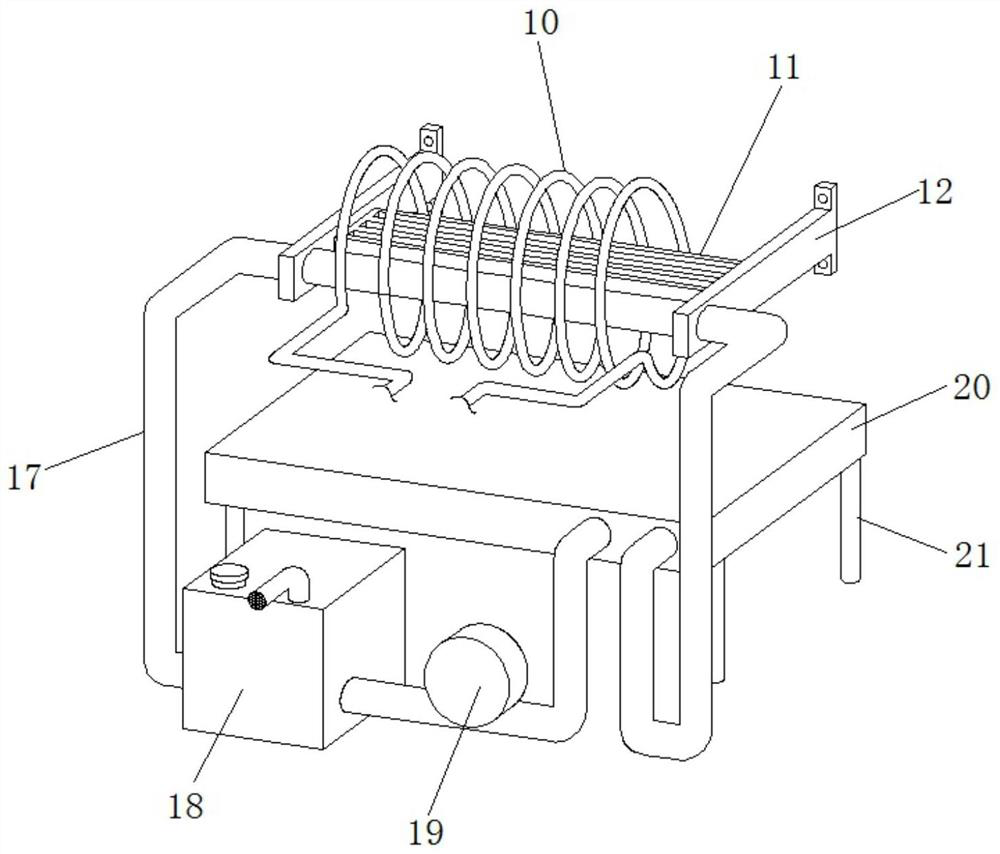

Straw drying device utilizing induction heating and provided with double heating structures

InactiveCN113048769AEasy to fixIncrease contact areaDrying gas arrangementsDrying machines with progressive movementsControl switchScreen filter

The invention discloses a straw drying device utilizing induction heating and provided with double heating structures. The straw drying device comprises a conveying belt mechanism, the conveying belt mechanism is driven by a servo motor fixedly installed on the side wall of the right end of the conveying belt mechanism, and first supporting frames are fixedly installed on the lower surfaces of the two ends of the conveying belt mechanism correspondingly. A protective cover is arranged on the outer side of the middle position of the conveying belt mechanism, two fans are evenly and fixedly installed on the top of the protective cover in the length direction of the conveying belt mechanism, filter screens are fixedly installed on the upper surfaces of the two fans, and a control switch is fixedly installed at the upper left end of the front face of the protective cover. A water tank opening is formed in the lower end of the front face of the protective cover, and a low-frequency power source is electrically connected with an induction hollow copper pipe coil fixedly arranged in the protective cover in the length direction of the conveying belt mechanism. The induction heating mode is adopted, the heating speed is high, the temperature is high, dual heating structures are adopted, and rapid drying and heating of straw can be achieved.

Owner:史玉芳

Bamboo strip drying device

InactiveCN108278875AGood drying effectReduce humidityDrying gas arrangementsDrying machines with progressive movementsAgricultural engineeringAir pump

The invention discloses a bamboo strip drying device. The bamboo strip drying device comprises a base plate and a drying chamber; the drying chamber is arranged above the middle part of the base plate; a plurality of transmission rollers are arranged at the internal lower portion of the drying chamber; the transmission rollers are connected through a bracket and are fixed to the internal left andright sides of the drying chamber; the left and right ends of the internal upper portion of the drying chamber are symmetrically provided with ultraviolet lamps; the left side of the internal upper portion of the drying chamber is provided with an exhaust fan component; the right side of the exhaust fan component is provided with a temperature sensor; the temperature sensor is positioned at the middle of the internal upper portion of the drying chamber; the right end of the temperature sensor is provided with an air blowing hood; the upper portion of the air blowing hood is connected with an air blower through a connecting pipe; the air blower is positioned at the middle of the external upper portion of the drying chamber; the right end of the air blower is connected with a water removingfilter; the right end of the water removing filter is connected with a circulating air pump; and the right end of the circulating air pump communicates with the middle of the right end of the drying chamber. The bamboo strip drying device disclosed by the invention is simple in structure, good in heating and drying effect, high in drying speed, good in drying effect and beneficial for popularization.

Owner:赵耀祥

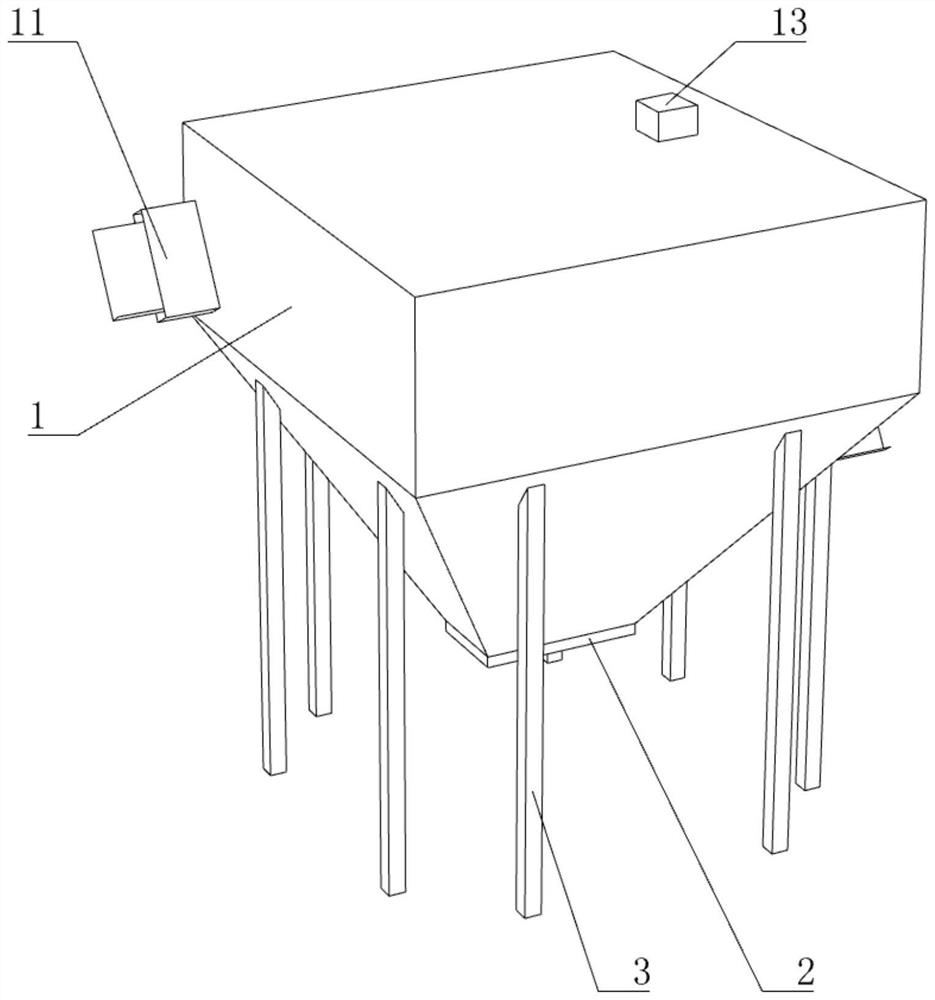

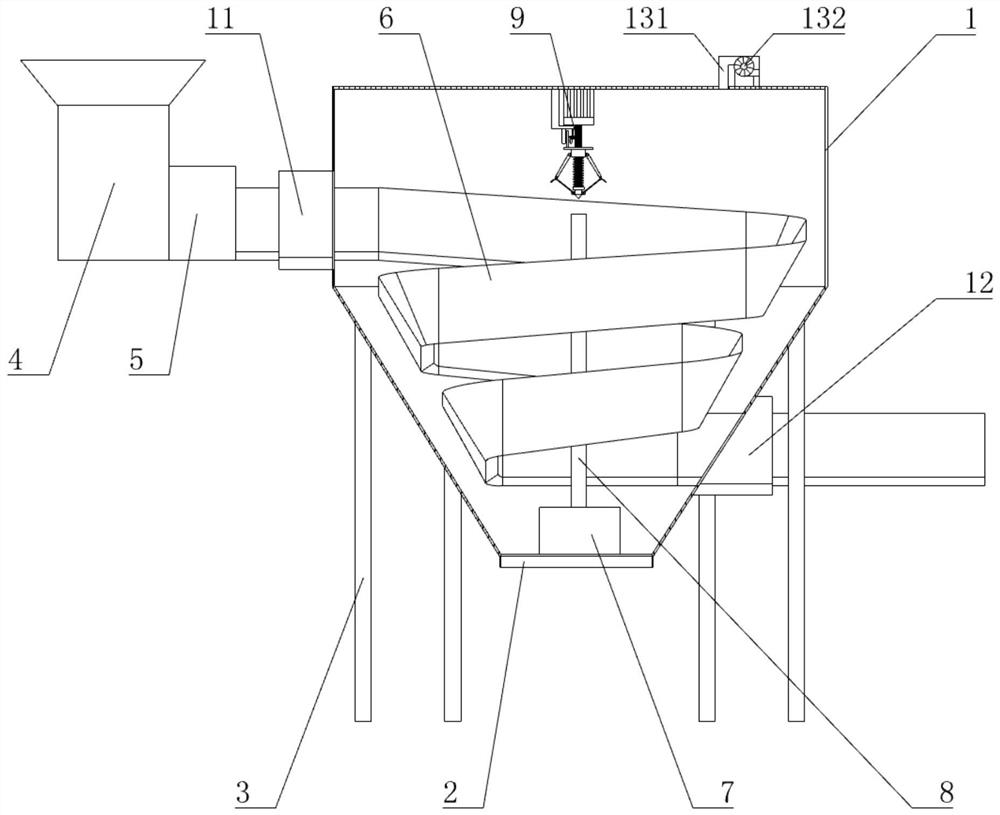

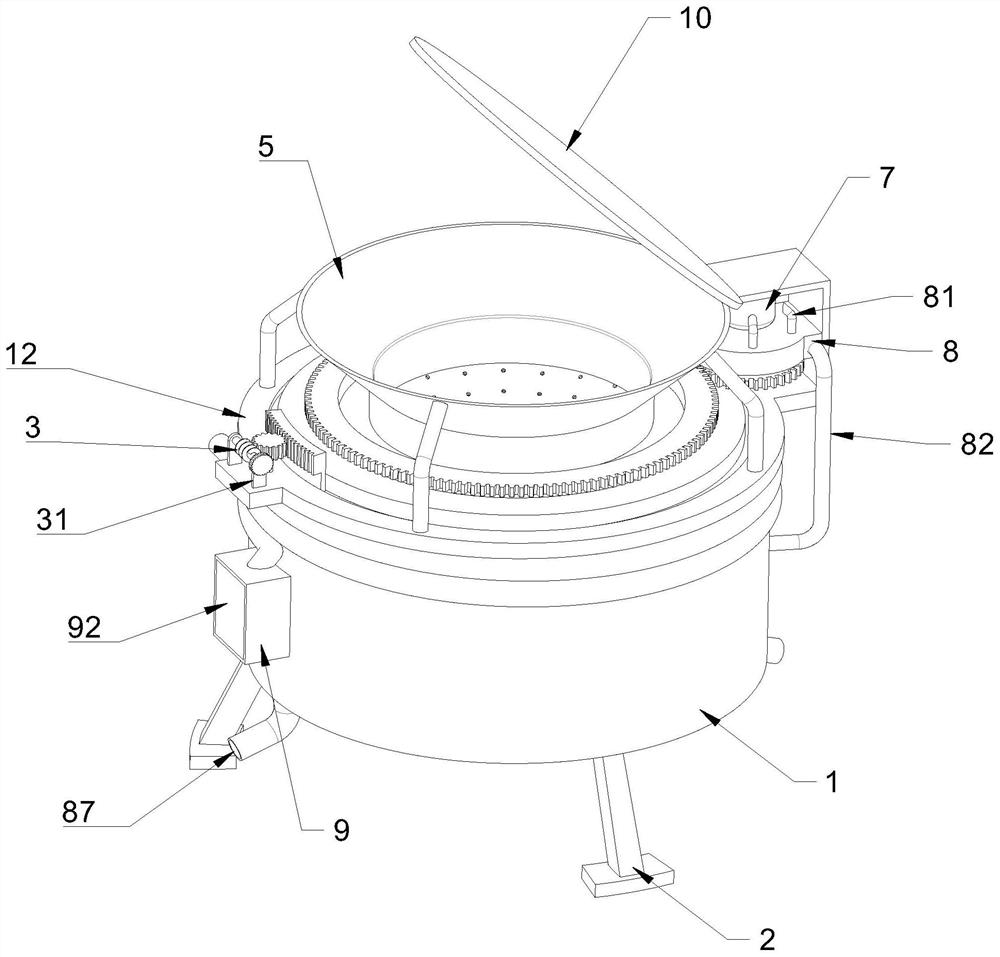

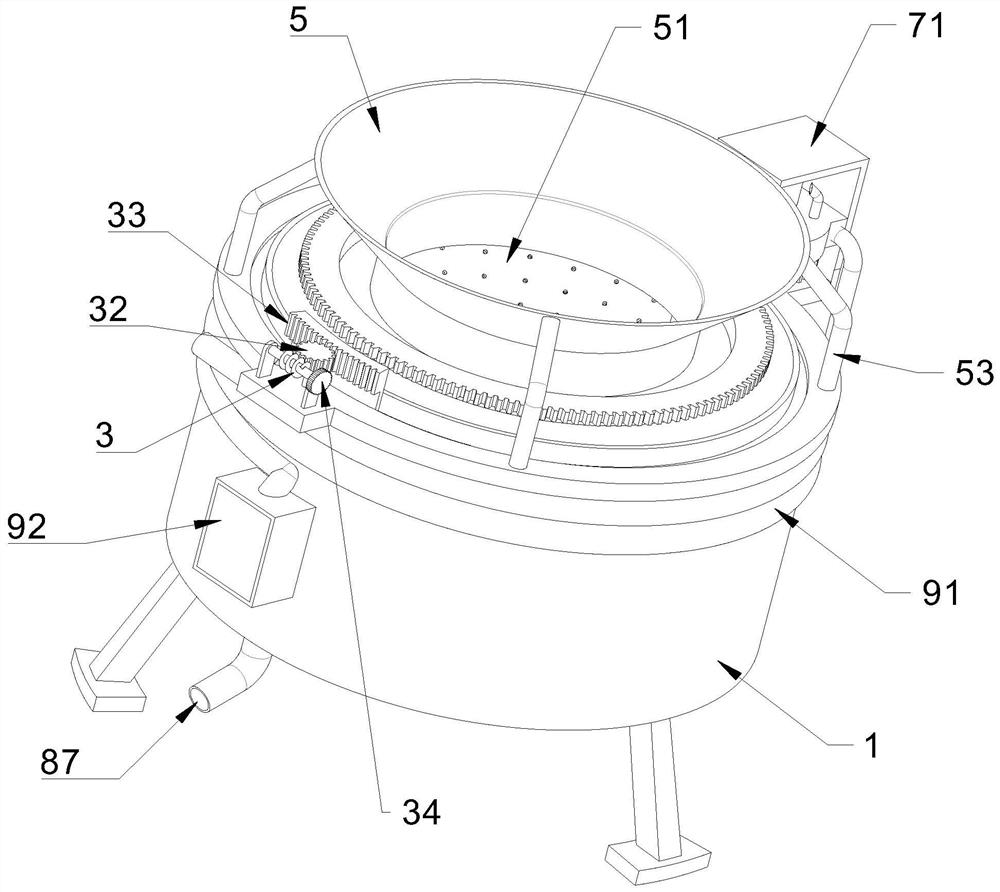

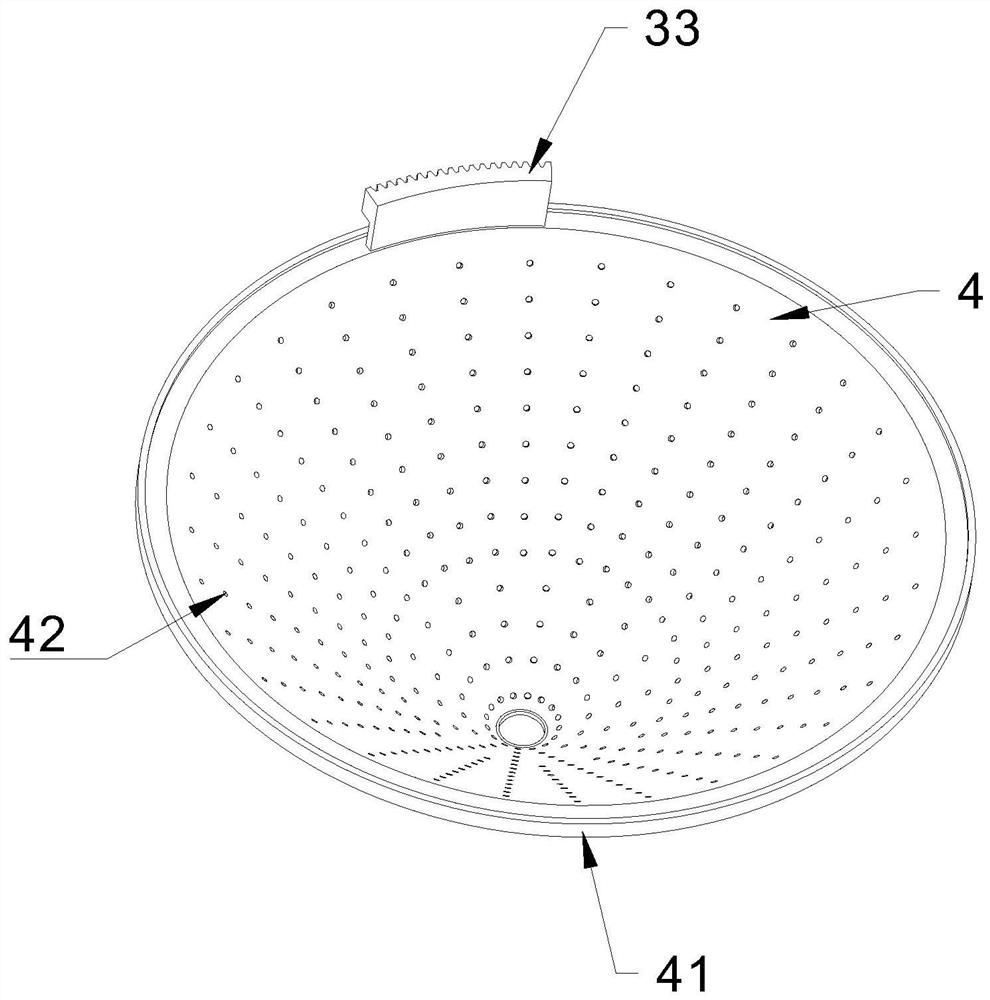

Rapeseed drying equipment

PendingCN114136064ARealize the filtration and screening requirements of particle sizeRealize filtering and sieving needsSievingScreeningEngineeringRapeseed

The invention relates to the technical field of rapeseed processing, in particular to rapeseed drying equipment which comprises a drying box body, an outer cylinder, an inner cylinder and supporting legs, the supporting legs are fixedly installed on the outer wall of the bottom of the drying box body, an adjusting mechanism is arranged at the top of the outer cylinder, and a stirring component is arranged on the inner wall of the inner cylinder. A driving part is arranged at the top of one side of the drying box body, and a drying mechanism is arranged in the space between the inner wall of the drying box body and the outer wall of the outer cylinder. Finally, through meshing of the gear and the arc-shaped toothed plate, the size of the overlapped filtering holes of the first sieve holes and the second sieve holes is driven to be adjusted, the filtering and screening requirements for different rapeseed particle sizes can be met, the applicability is improved, the arc-shaped toothed plate can be locked through the worm, the situation that the size of the overlapped filtering holes of the first sieve holes and the second sieve holes is changed is avoided, and the practicability is high. And the filtering and screening process can be continuously carried out, and the device runs stably and reliably.

Owner:九江市彭泽县宏兴油脂有限公司

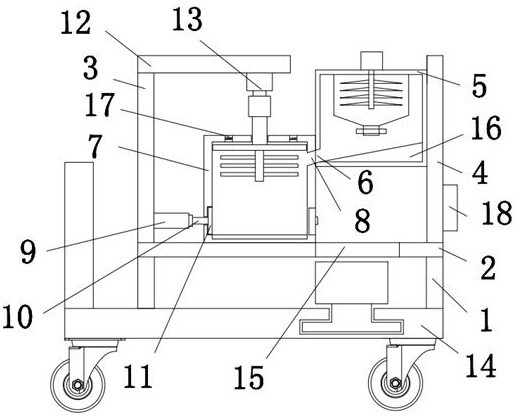

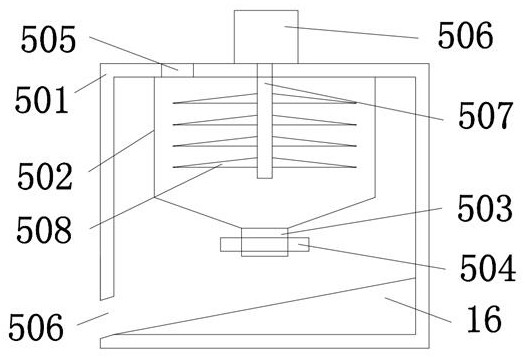

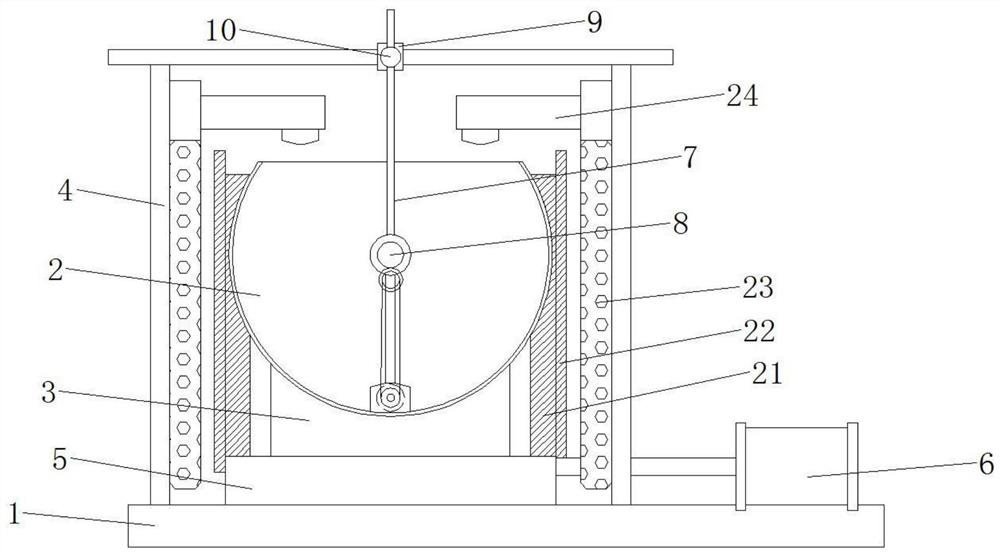

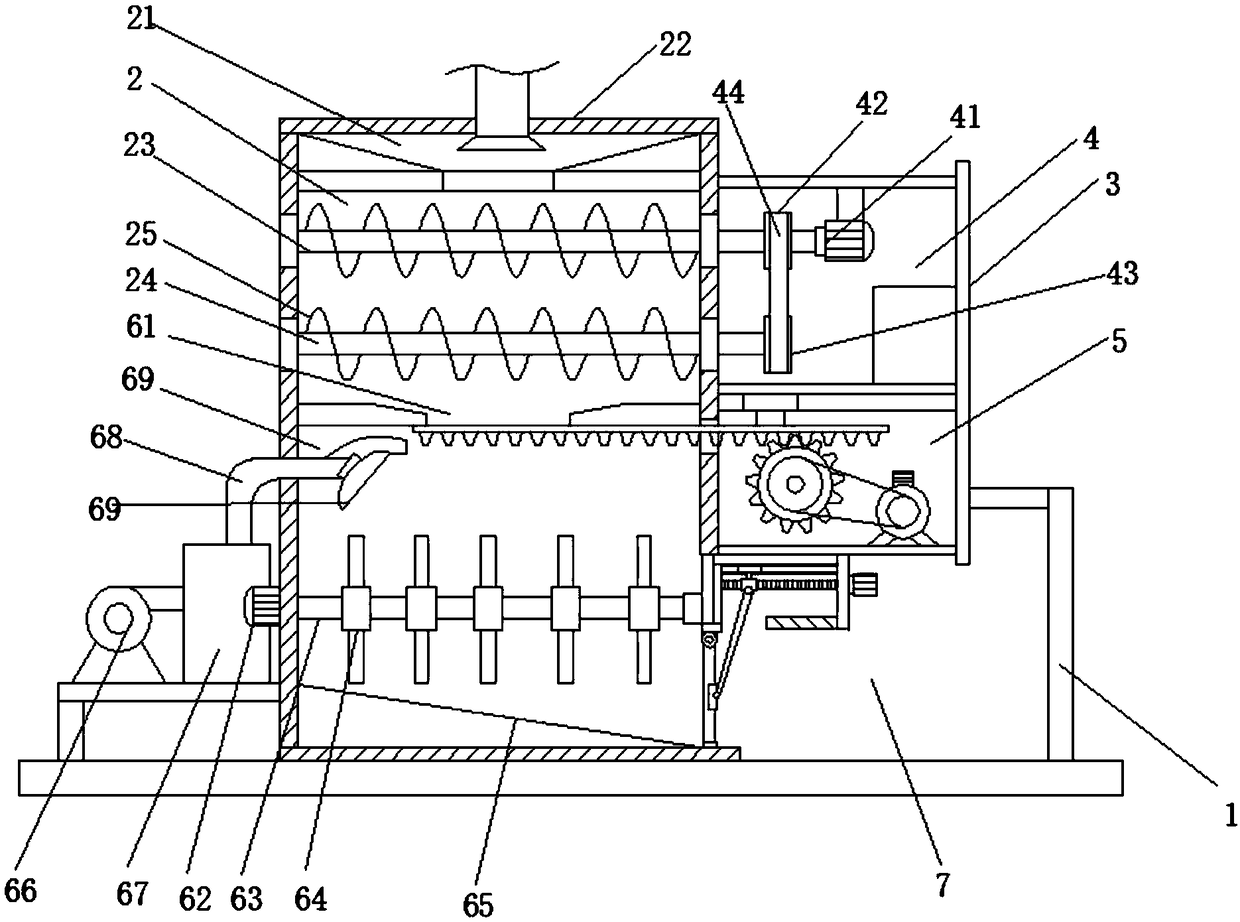

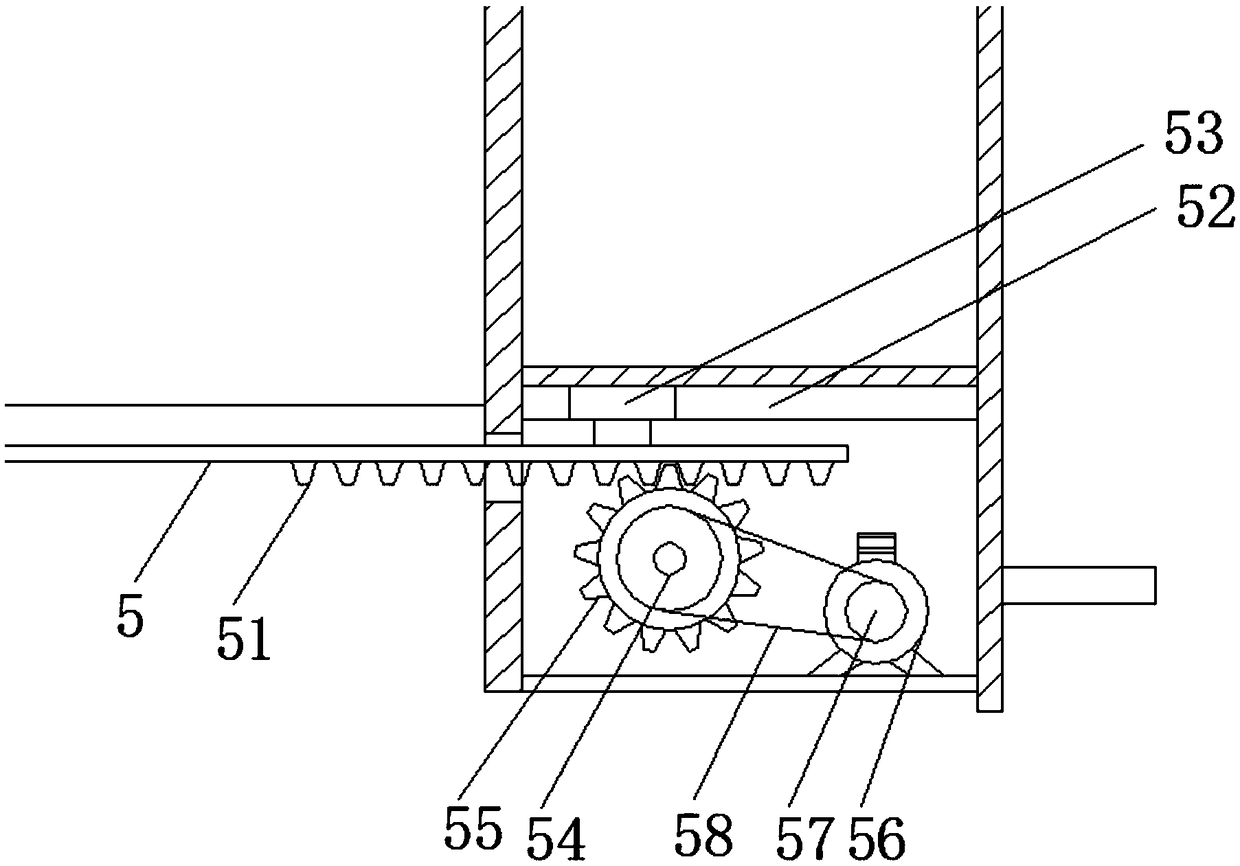

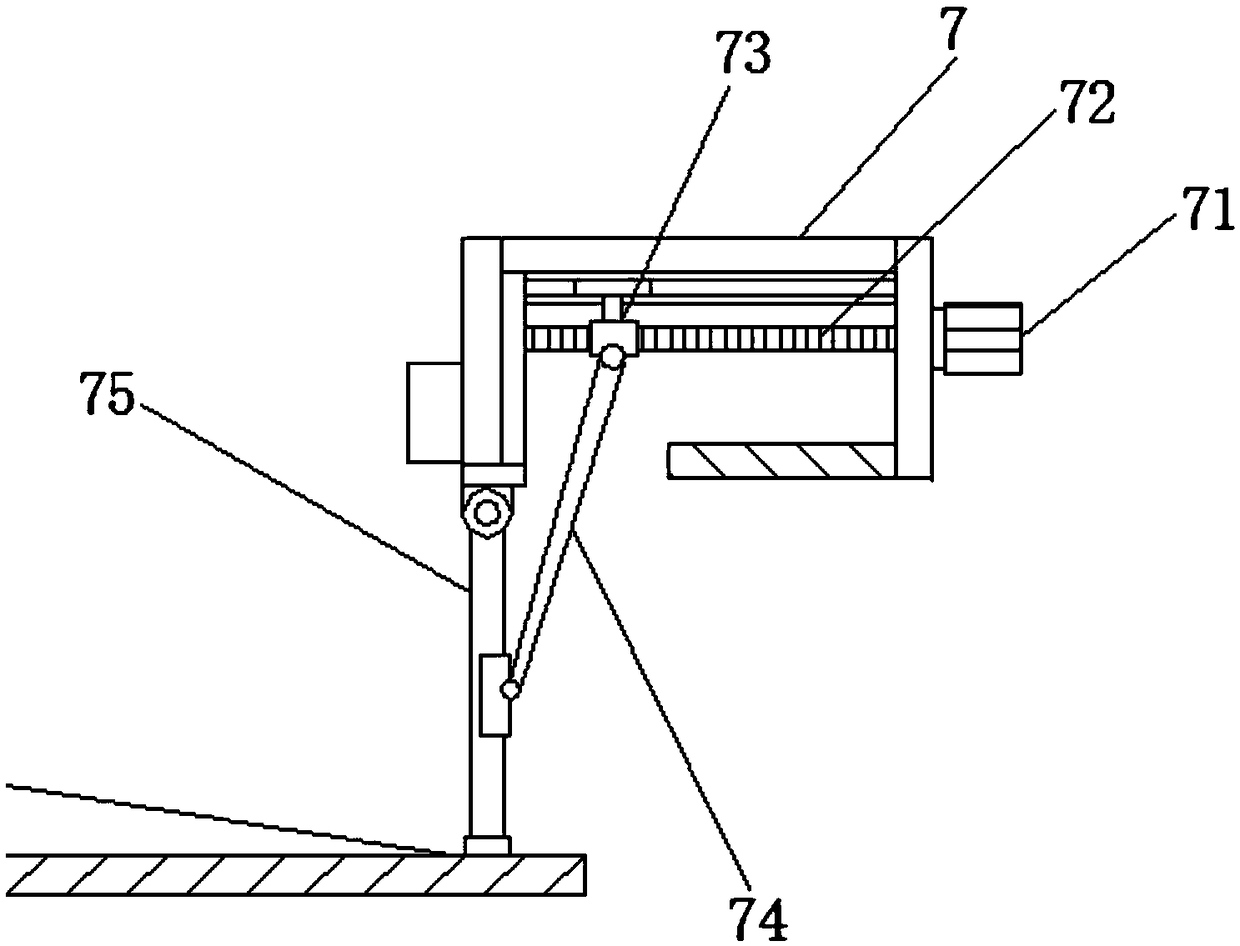

Movable sludge treatment equipment

InactiveCN111908763ADry full sideAll aspects of dryingSludge treatment by de-watering/drying/thickeningDispersed particle filtrationSludgeMechanical engineering

The invention discloses mobile sludge treatment equipment, and belongs to the field of sludge treatment. The equipment comprises four groups of supporting legs, wherein the tops of the supporting legsare fixedly connected with a bottom plate, the left and right sides of the top of the bottom plate are fixedly connected with a left supporting plate and a right supporting plate respectively, the upper half portion of the left side of the right supporting plate is fixedly connected with a stirring mechanism, a discharging port is formed in the bottom of the left side of the stirring mechanism, impurities in sludge are crushed through the stirring mechanism, then the sludge falls into the discharging port, the sludge enters a drying mechanism through a feeding port, the drying mechanism heatsand dries the sludge, a propelling mechanism further heats and dries the sludge in the drying mechanism, the sludge is stirred to be dried comprehensively, a first telescopic air cylinder pushes a push plate to push out the dried sludge, and a moving mechanism can easily move the equipment to a proper position so as to bring convenience to workers, so that a large amount of manpower and materialresources are saved, and the sludge is dried more comprehensively.

Owner:甘书学

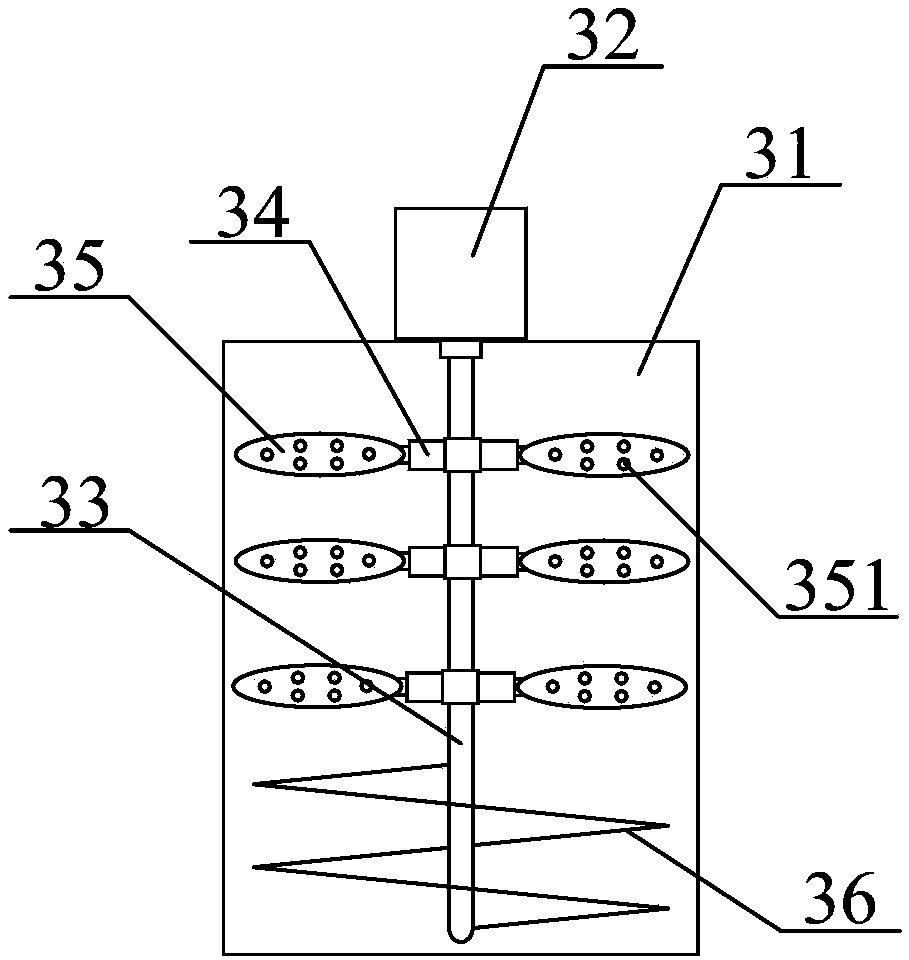

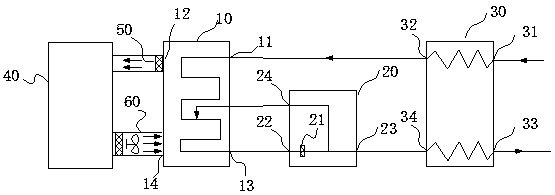

Sludge moisture content control device and moisture content adjustment method

PendingCN109485226AImprove efficiencyImprove heating and drying effectWater treatment parameter controlSludge treatment by de-watering/drying/thickeningSludgeMoisture

The invention discloses a sludge moisture content control device. The sludge moisture content control device comprises a drying device for heating and dehydrating sludge and further comprises a detection device which is arranged behind the drying device and is used for carrying out online detection on the sludge moisture content; a high-temperature dry air inlet and a low-temperature non-dry air outlet are arranged at one side of the drying device, and a low-temperature non-dry sludge inlet, a high-temperature dry sludge outlet and a sludge recycling inlet are arranged at the other side of thedrying device; the detection device comprises a detection inlet, a qualified sludge outlet and an unqualified sludge outlet, which are communicated with the high-temperature dry sludge outlet; and the unqualified sludge outlet is communicated with the sludge recycling inlet of the drying device. Compared with the prior art, the sludge moisture content control device provided by the invention hasthe advantages of optimal heating and drying effect, high efficiency, stable moisture content of the treated sludge, great single-time treatment amount of the sludge, energy source saving, economic efficiency and environment protection.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

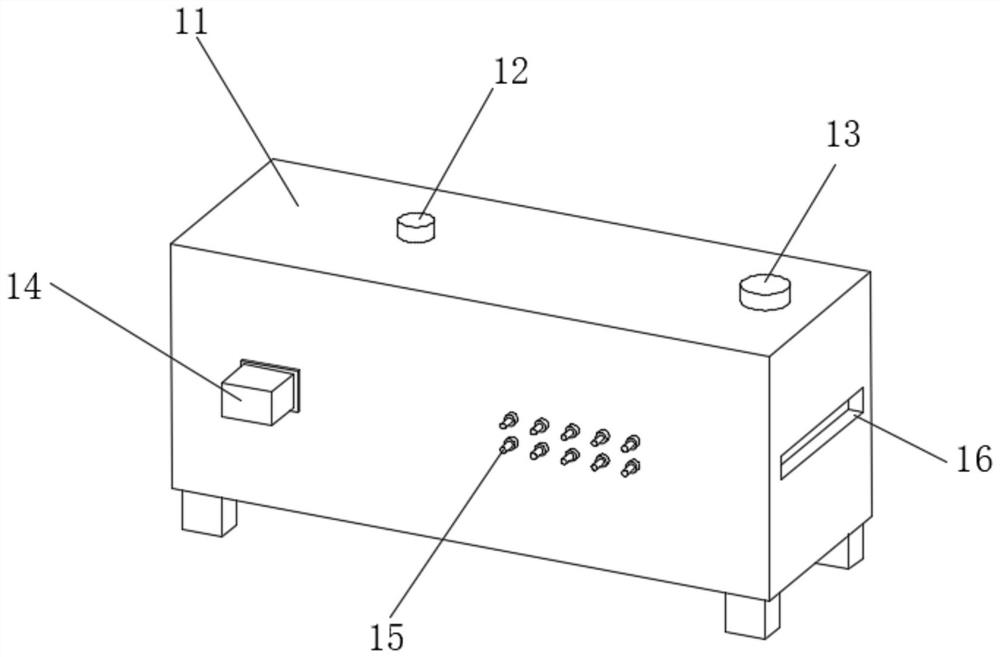

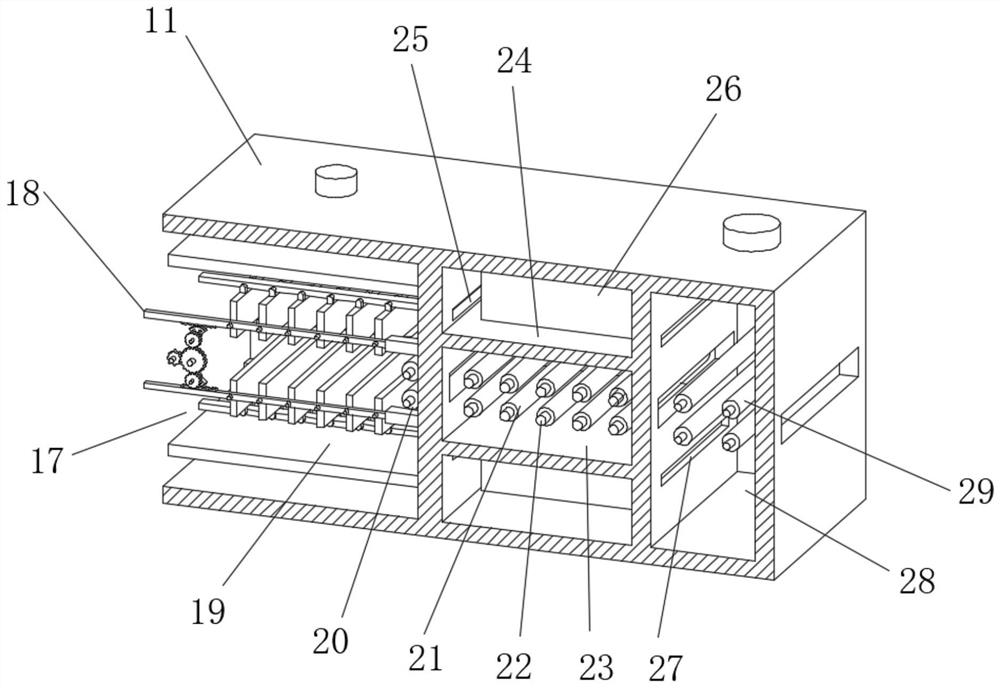

Drying machine special for electroplating production line

InactiveCN106196959AImprove shipping efficiencyIncrease the heating areaDrying machines with progressive movementsDrying solid materialsProduction lineEngineering

The invention discloses a drying machine special for an electroplating production line. The drying machine comprises a drying machine shell, heating devices and a conveying device; the drying machine shell is of a cuboid structure and comprises an aluminum strip outlet and an aluminum strip inlet, the aluminum strip inlet is located at the lower part of one side of the drying machine shell, and the aluminum strip outlet is located at the upper part of one side of the drying machine shell; the conveying device comprises a bottom conveying roller and a top conveying roller, and the bottom conveying roller and the top conveying roller rotate clockwise; the number of the heating devices is four, the heating devices sequentially comprise a first heating device, a second heating device, a third heating device and a fourth heating device from bottom to top and further comprise fixed plates and a plurality of heating plates, the fixed plates are horizontally arranged, and the heating plates are arranged on the fixed plates in an inclined mode. The interior of the drying machine is designed, the unique heating mechanism is adopted, and therefore the drying machine can fit with the operation tracks of aluminum strips, the heating and drying effect is good, and the drying efficiency is high.

Owner:扬中市宏飞镀业有限公司

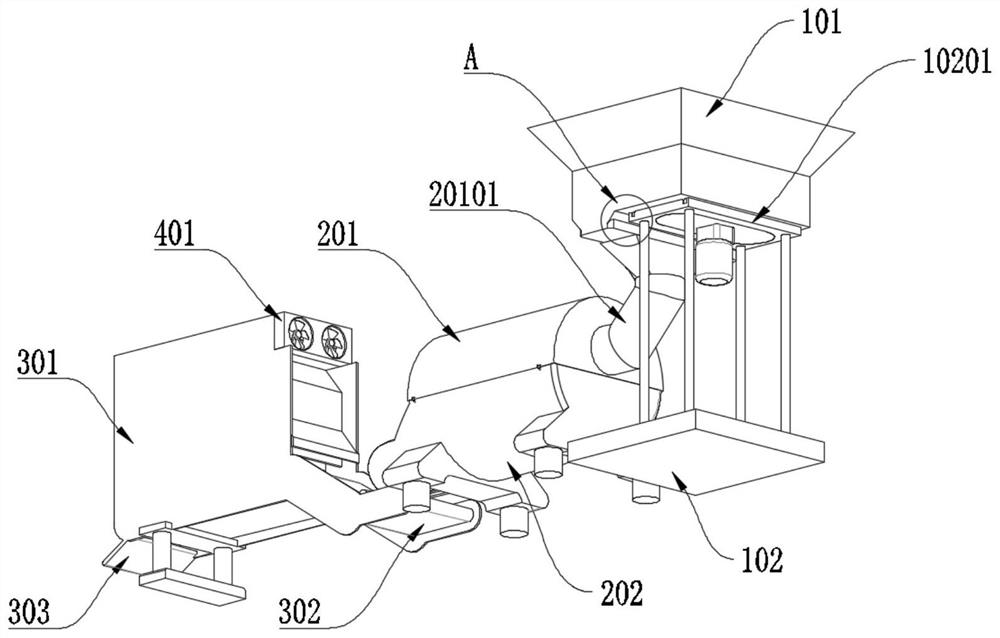

Swing type raw material drying device for food processing

InactiveCN111780519AImprove Flip EffectImprove heating and drying effectDrying gas arrangementsDrying chambers/containersProcess engineeringControl theory

The invention relates to the field of food processing and specifically discloses a swing type raw material drying device for food processing. The swing type raw material drying device for food processing comprises a base, a drying drum, a heating cover and a support. A fixed block is fixedly mounted on the top of the support. A vertical rotary sleeve is rotatably mounted on the fixed block. A pushrod slidably penetrates through the rotary sleeve. The lower end of the push rod is fixedly connected to a rotary shaft located on the center axis of the drying drum. The lower ends of two supportingconnecting rods are fixedly connected with horizontal swing seats. A horizontal transmission shaft is coaxially and rotatably mounted in the swing seats. A shifting roller is coaxially fixed to the transmission shaft. The swing type raw material drying device for food processing drives food in the drying drum to swing through a sliding base moving left and right so that food can make contact withthe bottom of the drying drum to be heated. During left and right movement, the push rod on the top is inclined relatively to drive the rotary shaft at the lower end to rotate, so that the swing seats of the swing type raw material drying device are attached to the inner wall of the drying drum to move and push the food inside the drying drum to move.

Owner:谢岩

Foundry sand incremental fast-drying equipment based on iron piece

ActiveCN111811215AImprove flowTo achieve the effect of breaking upGranular material dryingPreliminary solid treatment for dryingEngineeringCaking

The invention provided foundry sand incremental fast-drying equipment based on an iron piece. The equipment comprises a feeding structure. The feeding structure is mounted on the rear end of a heatingstructure, and a discharging structure is mounted on the front end of the heating structure. The top of the discharging structure is provided with a cooling structure. The feeding structure comprisesa feeding tank, supporting columns, and a discharging tank. The feeding tank is directly mounted on the top of a supporting plate. Four vertical supporting columns are fixed to the supporting plate.A mounting plate is fixed to the tops of the four supporting columns. The discharging tank is mounted at the bottom of the front end of the feeding tank. The bottom of the feeding tank is provided with an inclined plane sliding to the discharging tank. Foundry sand entering into the feeding tank is usually in a caking state, and needed to be broke up in the feeding tank. The feeding tank is directly mounted on a mounting sliding slot, so that the feeding tank can slide. Meanwhile, the feeding tank can be driven to shake when a direction-deviating wheel mounted at the bottom of the feeding tankrotates, so that the dispersing effect of the foundry sand block under the shaking of the feeding tank can be realized.

Owner:双峰县建设机械有限责任公司

Environment-friendly sludge drying treatment device

InactiveCN108892359AIncrease contact areaImprove heating and drying effectSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgePulp and paper industry

The invention discloses an environment-friendly sludge drying treatment device. The environment-friendly sludge drying treatment device comprises a machine case, wherein a primary drying cavity, a secondary drying cavity and a discharging cavity are formed in the machine case, a stander is mounted on the rear side of the machine case, the stander is divided into a first transmission frame and a second transmission frame, and a discharging hole is formed between the secondary drying cavity and the primary drying cavity in a communicated manner; a baffle is arranged at a discharging hole and istransversely mounted in the machine case; a driving roll and a driven roll are respectively mounted in the second transmission frame, and the driving roll and the driven roll are connected through a second transmission belt; and a crushing motor is mounted at the front end of the secondary drying cavity, and a crushing rotating shaft is transversely mounted in the secondary drying cavity. According to the environment-friendly sludge drying treatment device, solidified agglomerated sludge is crushed, the sludge can be further aired, and meanwhile, the sludge is crushed into powder, so that thesubsequent discharging operation is facilitated.

Owner:张秀英

Towel drying rack

PendingCN109620034AWith heating functionImprove heating and drying effectDomestic applicationsEngineeringMechanical engineering

The invention provides a towel drying rack, and relates to the technical field of towel racks. The towel drying rack is provided with one or more bent plate parts used for placing towels and arrangedvertically; the bent plate parts have the function of heating and are used for drying the towels placed on the rack. According to the towel drying rack, the towels and heating towels are placed through the bent plate parts, large-area contact is realized between the towels and the bent plate parts, and therefore the effect of heating drying is good. In addition, the function of heating is integrated on the bent plate parts used for placing the towels, so that the towel drying rack is compact in structure.

Owner:NINGBO OULIN IND CO LTD

Drying device for wood-plastic floor

ActiveCN112414078BImprove heating and drying effectEasy to operateDrying machines with progressive movementsDrying solid materialsMechanical engineeringComposite material

The invention relates to the technical field of wood-plastic floor production, in particular to a drying device for wood-plastic floor, which includes a frame, a conveying platform installed on the frame for conveying wood-plastic floor, and a The heating body extending in the left and right direction, the outer wall of the heating body is sleeved with a number of heat dissipation and drying blocks distributed along the left and right direction of the heating body and used to be close to the upper surface, and the heating and drying effect is good.

Owner:浙江天博生物新材料股份有限公司

Filter cloth processing technology and device

ActiveCN113373574AEvenly heatedImprove heating and drying effectDrying solid materials with heatHeating/cooling textile fabricsPolyesterReciprocating motion

The invention discloses a filter cloth processing technology and device. The filter cloth processing technology comprises the following steps of raw material selecting, thread twisting, treating through a warping machine, gray fabric weaving, hot air drying, calendaring, ultrasonic edge cutting, gluing and steel button knotting, joint treatment and packaging. A raw material adopts a polyester product; the step of thread twisting is completed at a time by adopting three threads and one strand; after grey cloth enters a heating cavity, a gear driving part drives a moving rod to do horizontal reciprocating motion and can drive a plurality of sets of air outlet plates to swing around the axis of a mounting base at the same time, and air blowing openings conduct hot air drying on filter cloth in the reciprocating swing process, so that the filter cloth is heated evenly, and the heating and drying effect is improved; a cooling cavity is arranged behind the heating cavity, and the filter cloth passes through the heating cavity so as to be heated and then enters the cooling cavity so as to be rapidly cooled, so that the filter cloth is ensured to have certain tension; and a balance cavity can use air exhausted from the heating cavity to blow air to the cooled filter cloth, so that the temperature of the filter cloth is balanced.

Owner:烟台同兴过滤科技有限公司 +1

A cleaning system for water surface pollutants in water conservancy projects

InactiveCN109322293BReduced service lifeAchieve dryingWater cleaningSolid waste disposalMechanical componentsEnvironmental engineering

The invention discloses a system for cleaning water surface pollutants of water conservancy projects, and relates to the technical field of water conservancy projects. The invention comprises a support frame, a pair of support plates are fixed on one surface of the support frame; a first driven roller is rotatably connected between one end of the pair of support plates; a first driving roller is rotatably connected between the other ends of the pair of support plates; There is a salvage chain plate connected to the side surface of the driving roller and the first driven roller by transmission; the salvage claws are arranged in a linear array on the side surface of the salvage chain plate; one end of the first driving roller is fixed with a drying device. Through the function of the drying device, the present invention is beneficial to drain, dry and discharge the water on the pollutants salvaged by the pollutant cleaning device into the cabinet, so as to prevent the water on the pollutants from collapsing during the crushing and compressing process. Residues in the chassis cannot be discharged in time, causing the mechanical parts in the chassis to be corroded by the residual water, shortening the service life of the cleaning device, thereby affecting the progress of the water conservancy project.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

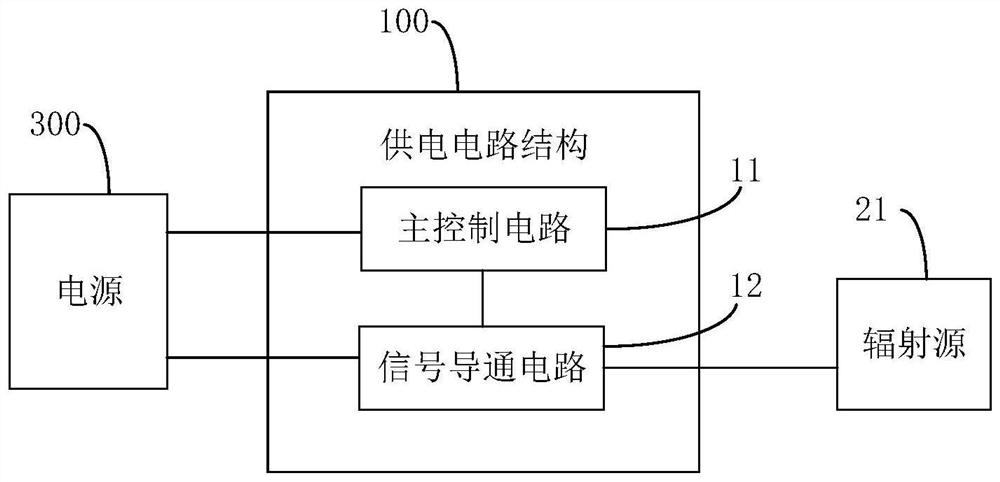

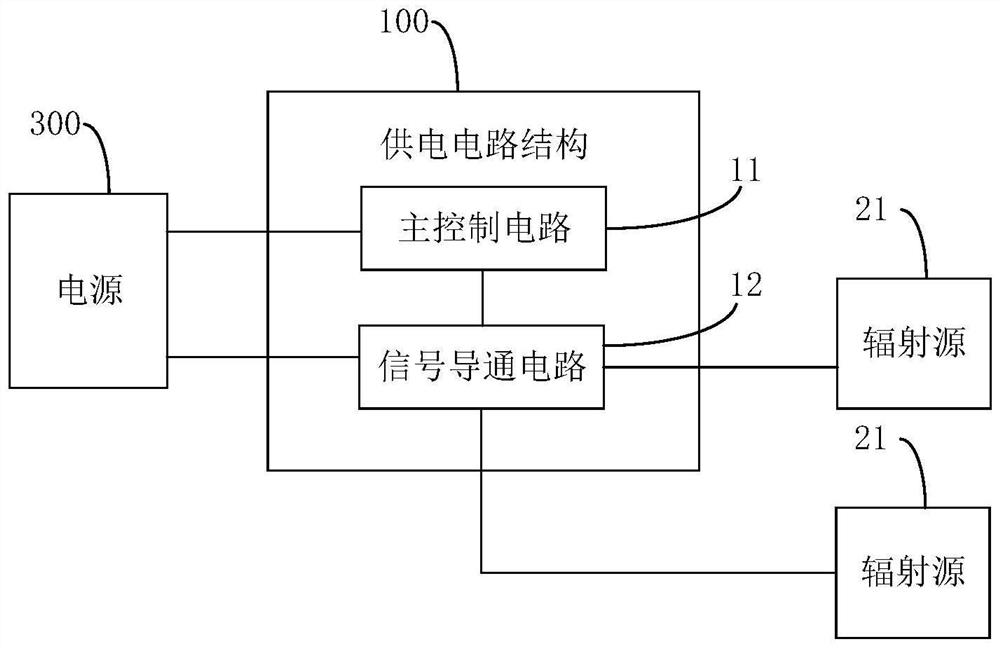

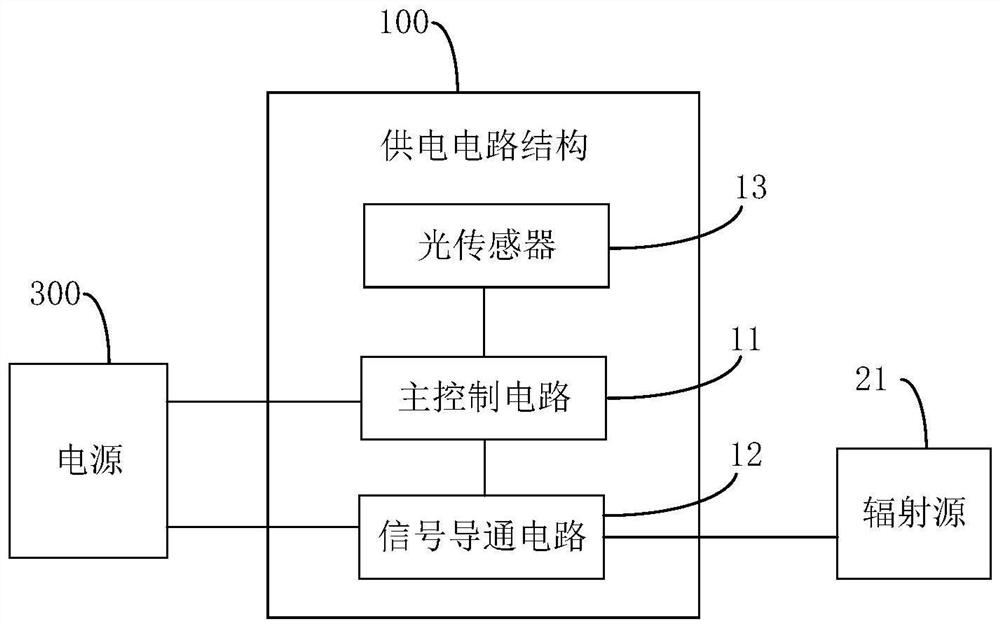

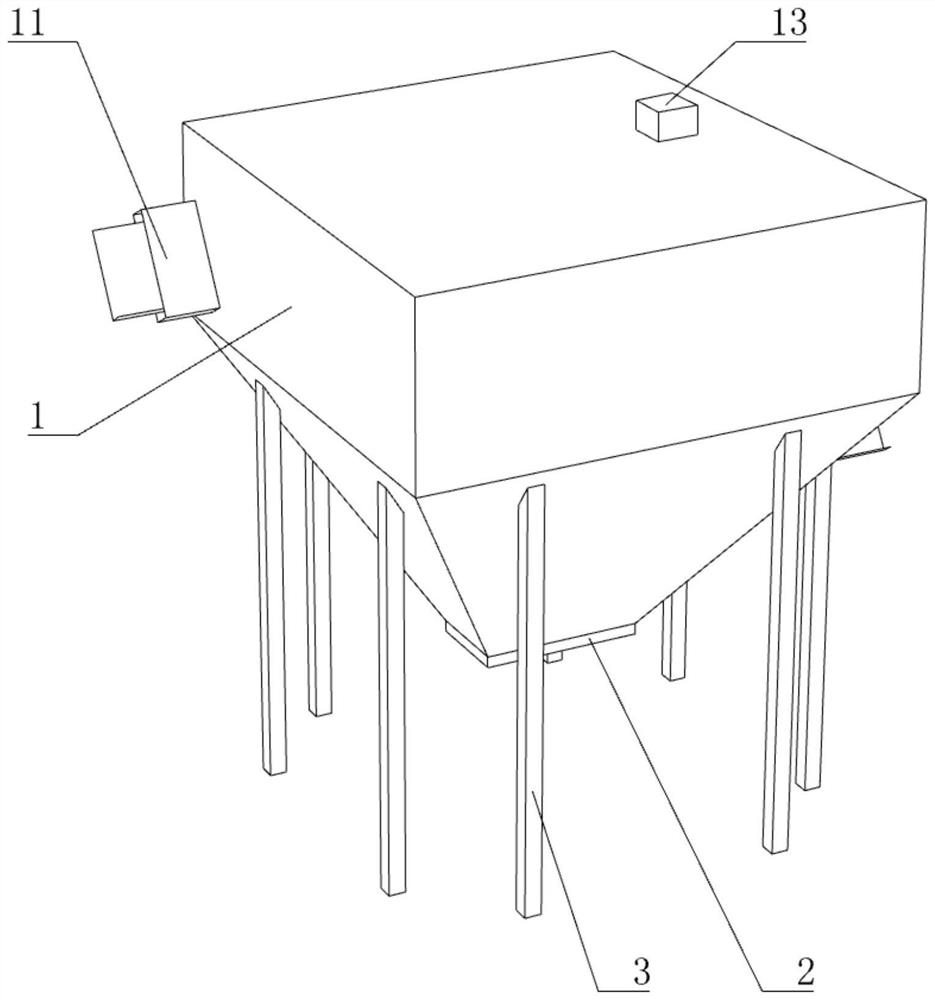

Power supply circuit structure, drying equipment, power supply set and power supply method

PendingCN114556736AGood heating and drying effectImprove heating and drying effectAc-dc conversion without reversalEmergency protective circuit arrangementsPhysicsFrequency band

A power supply circuit structure (100), a drying apparatus (200), a power supply kit (1000), and a power supply method. The power supply circuit structure (100) is used for being connected with a power supply (300) and supplying power to the radiation source (21), the power supply (300) provides an alternating current signal which changes periodically, the radiation source (21) can radiate light of a preset frequency band, and the power supply circuit structure (100) comprises a main control circuit (11) and a signal conduction circuit (12). The main control circuit (11) receives and detects the alternating current signal and generates a control signal with the same frequency as the alternating current signal according to a preset frequency band, and the control signal comprises a zero amplitude part; the signal conduction circuit (12) receives the alternating current signal and the control signal and generates an output signal, the amplitude of the output signal is zero at the zero amplitude part of the control signal, and the amplitude of the output signal corresponds to the amplitude of the alternating current signal at other parts of the control signal; when the output signal is input, the radiation source (21) is used for radiating light of a preset frequency band.

Owner:SZ ZUVI TECH CO LTD

A pickling sludge dewatering device

ActiveCN112759224BImprove uniformityReduce occupancySludge treatmentWaste water treatment from metallurgical processThermodynamicsEngineering

The invention discloses a pickling sludge dehydration device, comprising a dehydration chamber, the main body of the dehydration chamber is in the shape of a "chamfered platform", and the inner cavity of the dehydration chamber is provided with A spiral conveyor belt is equipped, a magnetron is arranged in the middle of the bottom of the inner cavity of the dehydration chamber, a vertical waveguide is connected above the magnetron, and a dehydration device is fixed directly above the output end of the waveguide. The microwave stirrer on the top of the chamber, the input end and the output end of the conveyor belt pass through the feed port and the discharge port of the dehydration chamber respectively, and the bearing surface of the conveyor belt is arranged obliquely and faces the waveguide and the microwave stirrer. The invention dehydrates the pickling sludge by means of microwave heating. The mud plate absorbs the microwave energy, thereby continuously increasing the temperature, and at the same time, the water in the mud plate is evaporated, thereby achieving the effect of dehydration, reducing environmental pollution and damage to the land occupy.

Owner:江苏亿洲再生资源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com