Roller used for heating, drying and continuous stirring to produce thermal regeneration mixture

A technology of recycled mixed materials and mixed materials, applied in roads, road repairs, roads, etc., can solve the problems of large power consumption and complicated equipment, and achieve the effects of low product cost, good effect and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described below with specific embodiments in conjunction with the accompanying drawings.

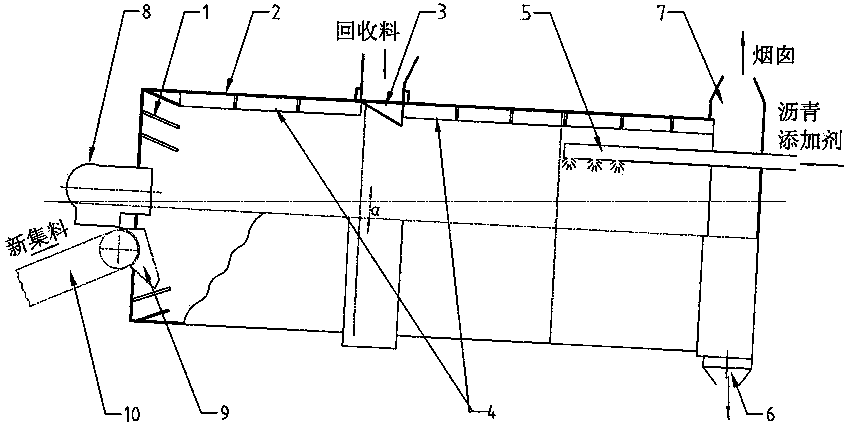

[0013] figure 1 It is a structural schematic diagram of a drum that heats, dries and continuously stirs to produce thermal regeneration mixture in the present invention. In one drum, a drying heating area for new aggregates, a drying heating area for recycled materials and a mixing area for recycled mixtures are set;

[0014] The present invention is arranged at one end of the drum with a burner, and the inner new aggregate guide plate 1, the inner wall 2 of the drum and the turning vane 4 constitute the heating and drying area (high temperature area) of the new aggregate; the new aggregate passes through the new aggregate The material conveyor 10 enters the heating and drying area of the new aggregate from the new aggregate feed port 9 to realize the heating and drying of the new aggregate;

[0015] The recycled material inlet 3 arranged in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com