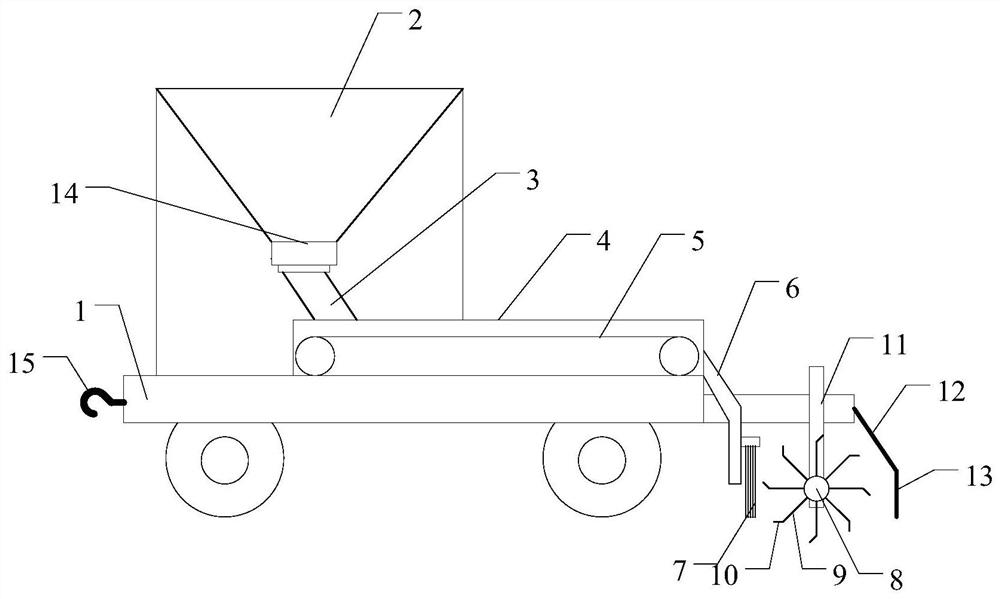

Pull-type ash distributing and mixing all-in-one machine

A trailer-type, all-in-one machine technology, applied in roads, road repairs, roads, etc., can solve problems such as inability to work at the same time, and the overall operating efficiency of road construction needs to be improved, so as to achieve the effect of improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0023] like figure 1 As shown, the present invention provides a trailer-type ash distribution and mixing integrated machine, comprising: a car body 1; Set on the vehicle body 1, the hopper 2 is a conical hopper with a wide top and a narrow bottom. The lower part of the hopper 2 is formed with a discharge opening 14. The crushing mechanism is arranged inside the hopper, and is close to The feeding opening is arranged, the conveying mechanism 5 is arranged inside a horizontally arranged conveying channel 4, one end of the conveying channel 4 has a feeding port, and the feeding port is located below the feeding port, The feed port and the discharge port are communicated through an inclined feeding pipe 3, the other end of the conveying channel 4 has a discharge port, and the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com