High-temperature alloy production waste gas self-adhesion treatment device

A high-temperature alloy and treatment device technology, which is applied in the field of self-adhesive treatment devices for waste gas produced by superalloys, can solve the problems of high frequency of filter screen clogging and low efficiency of waste gas treatment, so as to increase the interception effect and restore sticky adsorption performance and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

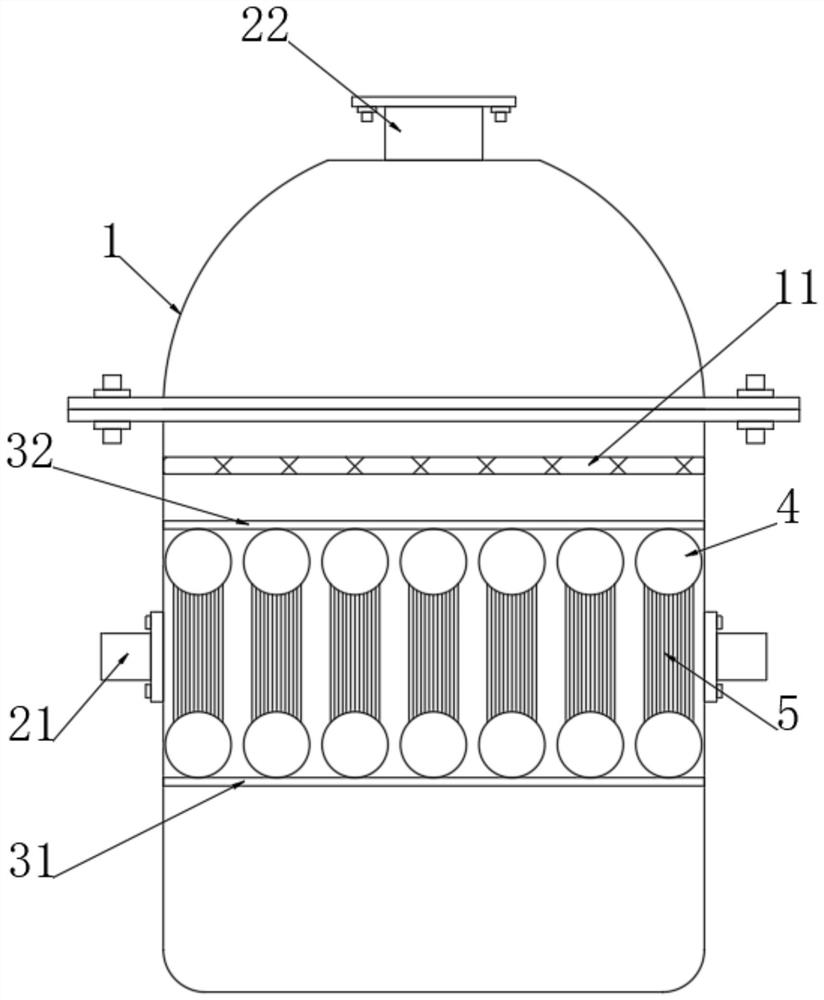

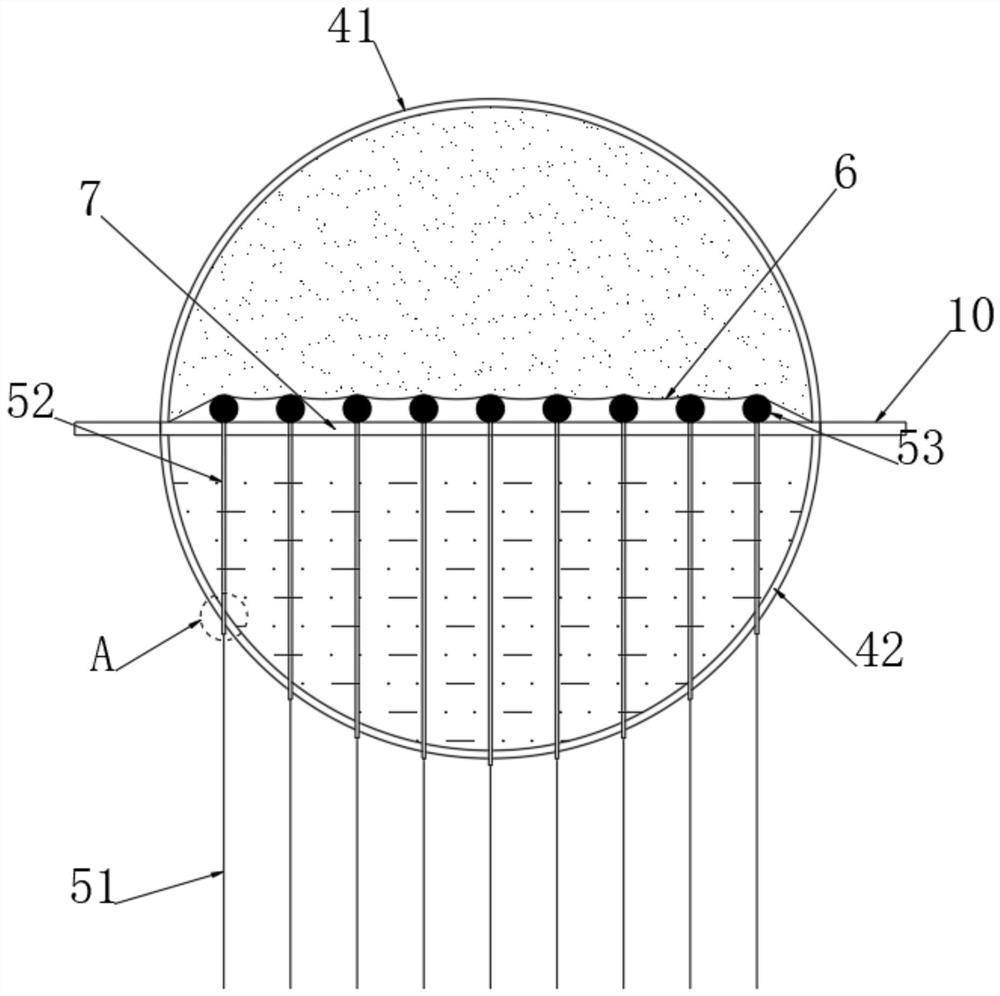

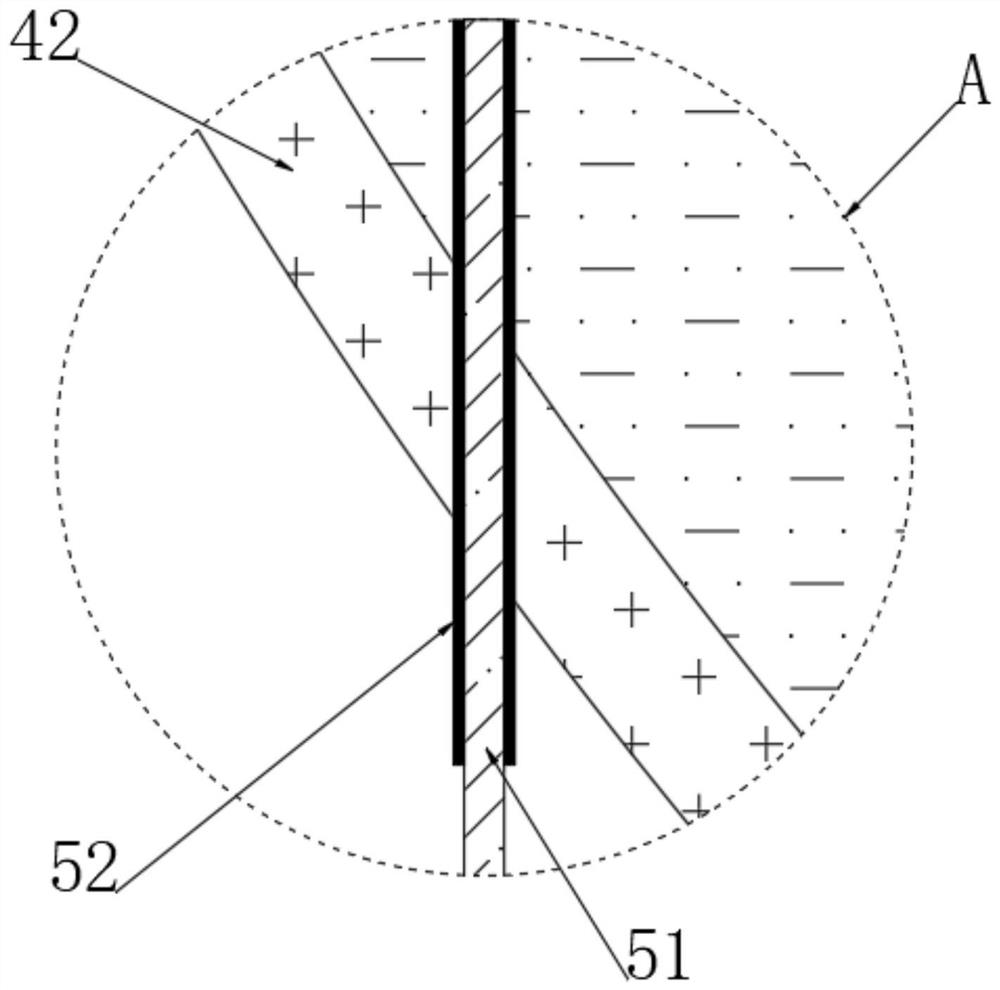

[0042] see figure 1 , a self-adhesive treatment device for high-temperature alloy production waste gas, including a device body 1, an air inlet 21 is fixedly connected to the left and right ends of the device body 1, an air outlet 22 is fixedly connected to the upper end of the device body 1, the air inlet 21 and the outlet The air ports 22 are all connected to the device body 1, and the device body 1 is clamped with the lower bearing plate 31, the upper bearing plate 32 and the filter screen 11, and the filter screen 11, the upper bearing plate 32 and the lower bearing plate 31 are arranged in sequence from top to bottom , the lower bearing plate 31 is a hard solid sealing structure, and the upper bearing plate 32 has a rigid mesh structure, so that the alloy waste gas introduced through the air inlet 21 is concentrated and overflows upwards from the upper bearing plate 32, thereby effectively increasing the air pushing ball bundle The thrust of the received exhaust gas makes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com