Integrated mud stirring machine for operating paddy field

A slurry mixer and integrated technology, applied in the field of integrated operation paddy field mixer, can solve problems such as shortening the service life of the equipment, uneven bearing load, bearing wear, etc., to avoid the phenomenon of water digging, ensure efficiency, and reduce mixing The effect of mud resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

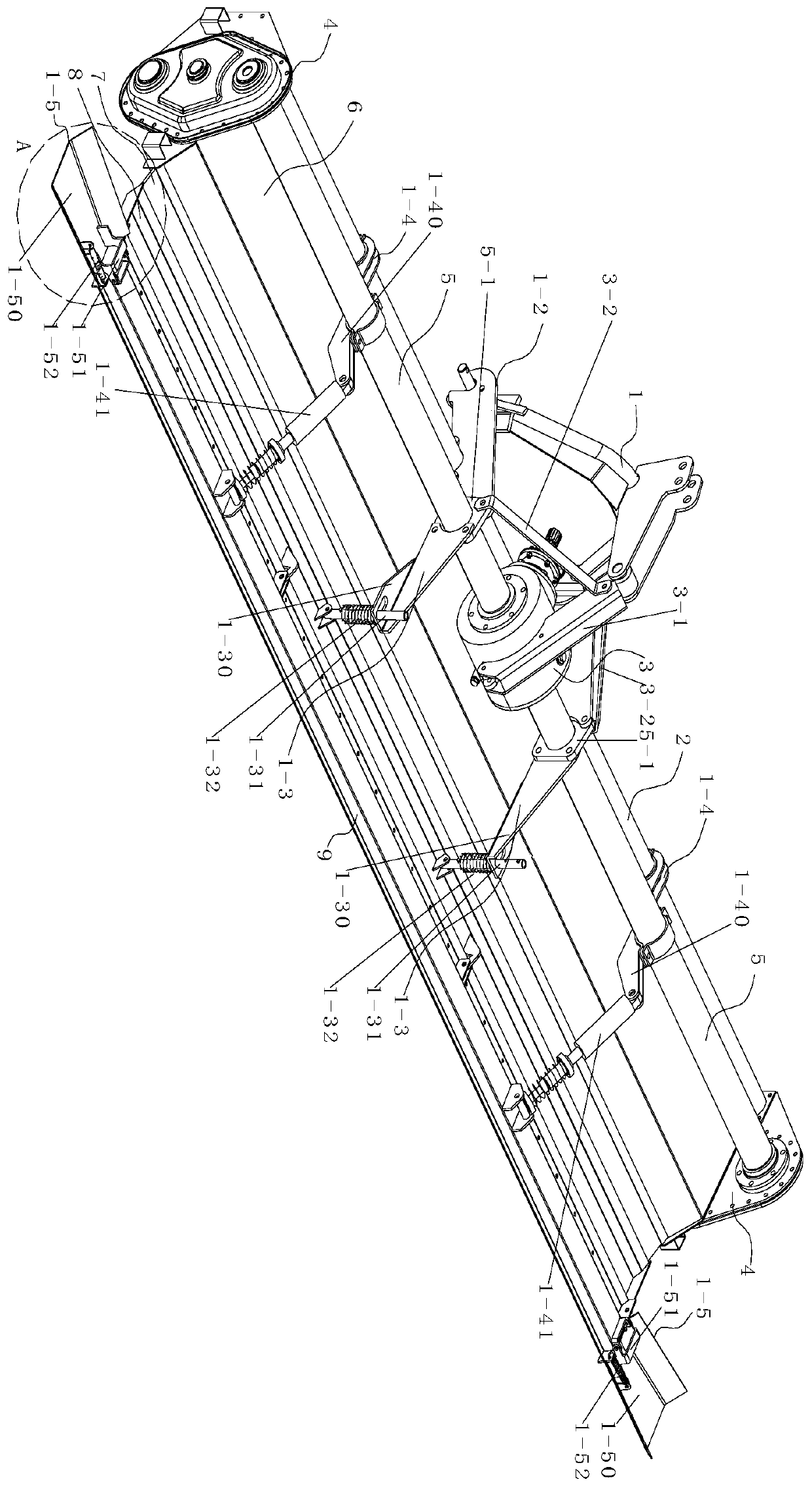

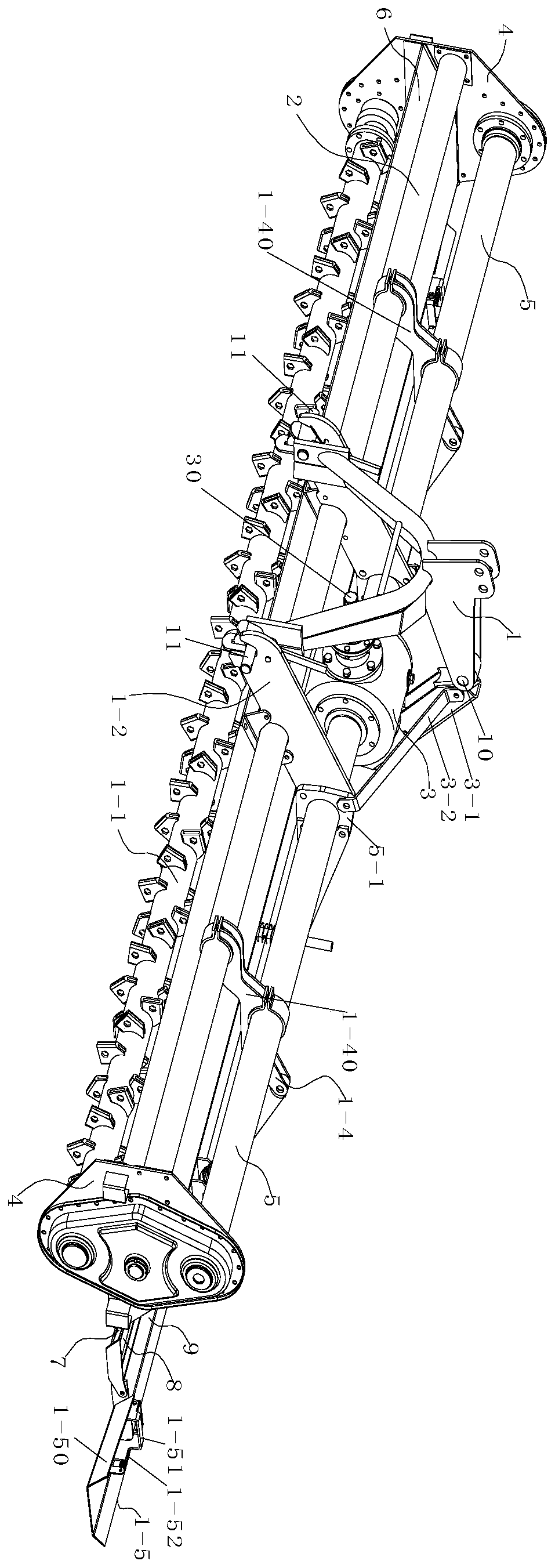

[0065] In this integrated operation paddy field mixer, the upper end of the three-point suspension frame 1 is connected with the diagonal stay rod 3-1 through the hinge joint 10, and the diagonal stay rod 3-1 is tightly connected with the gear box 3, and the diagonal stay rod 3-1 is two A stabilizer bar 3-2 is arranged symmetrically on the side, and one end of the stabilizer bar 3-2 is tightly connected to the side wall of the diagonal stay rod 3-1, and the other end is firmly connected to the connecting plate 5-1, and the lower end of the three-point suspension frame 1 is symmetrical Bearing pin 11 is provided, and pin shaft 11 is provided with through through hole, and the coupling tube of tractor rear end is worn on pin shaft 11, then passes through coupling tube and through hole through locking pin, then starts tractor, makes When the tractor moves backwards, the coupling cylinder moves backwards with the pin shaft 11, because the suspension lock 12 is composed of a suspens...

Embodiment 2

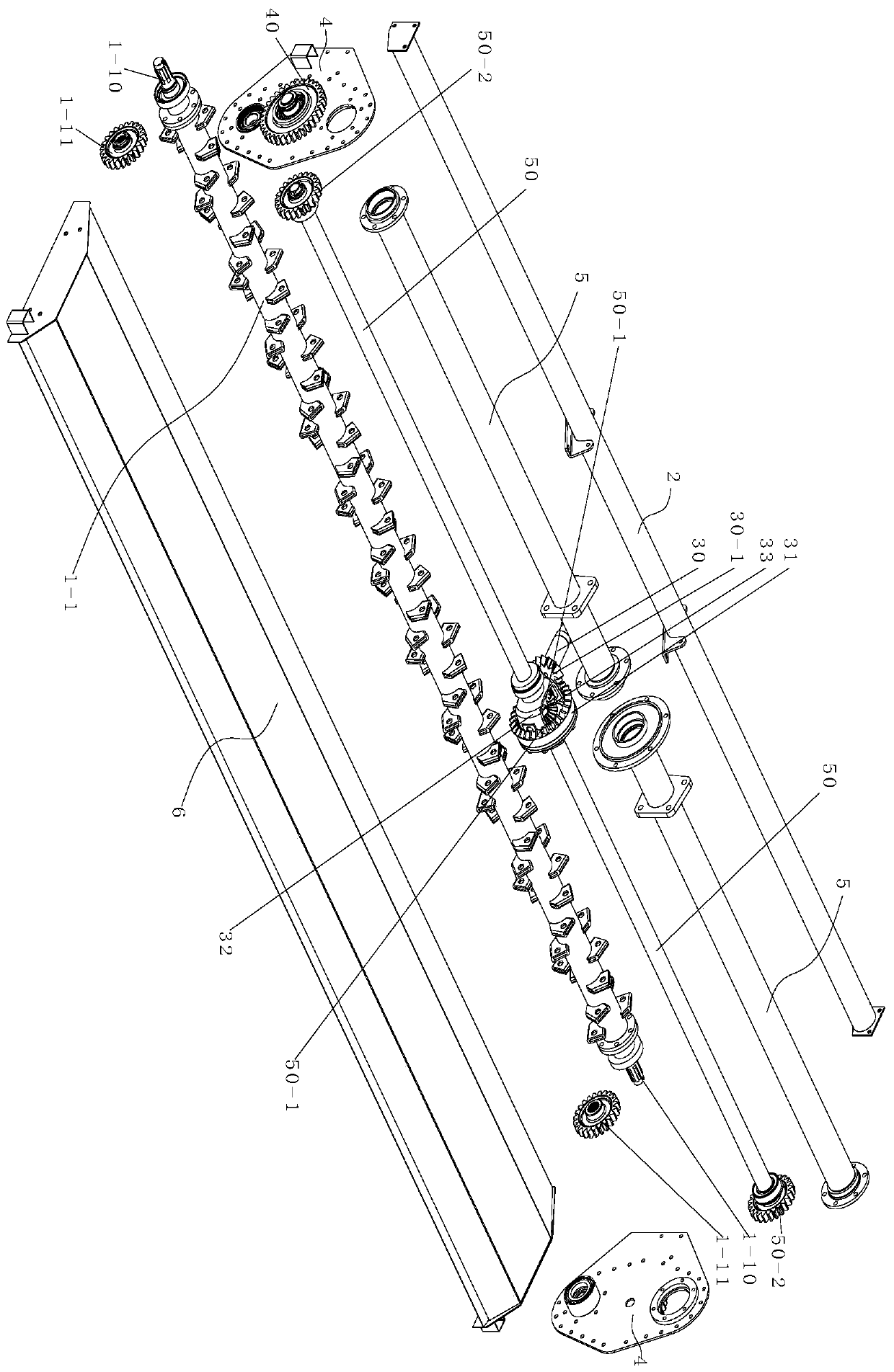

[0067] In this integrated operation paddy field mixer, the two ends of the mixing roller 1-1 are respectively provided with spline shafts 1-10, and the spline shafts 1-10 are rotatably connected to the lower end of the side panel 4 through bearings. The key shaft 1-10 is provided with a spur gear 2 1-11, the horizontal shaft sleeve 5 is provided with a rotating shaft 2 50, and one end of the rotating shaft 50 is provided with a spur gear 1 50-2, and the center of the side panel 4 is rotated. There is a reversing gear 40, and the spur gear 1 50-2 and the spur gear 2 1-11 are respectively externally meshed with the reversing gear 40. The front end of the gearbox 3 is provided with an input shaft 30, and the end of the input shaft 30 is located at the gear Bevel gear 1 30-1 is provided inside the box 3, and bevel gear 2 31 and planetary carrier 32 are arranged in the gear box 3, and bevel gear 1 30-1 meshes with bevel gear 2 31, and the center rotation of the planetary carrier 32 ...

Embodiment 3

[0069] In this integrated operation paddy field mixer, the platen mechanism 1-3 is composed of a limit plate 1-30, a support rod 1-31 and a compression spring 1-32, and the front end of the limit plate 1-30 is connected to the connecting plate 5-1 is tightly connected, the upper end of the support rod 1-31 passes through the limit plate 1-30, and the lower end is hinged with the hinge seat 1-80, and the compression spring 1-32 is sleeved on the support rod 1-31, The upper end of compression spring one 1-32 is in contact with the lower side of the limit plate 1-30, the lower end of compression spring one 1-32 is in contact with the pin passing through the support rod 1-31, and the limit plate 1-30 is installed horizontally so that the support The rod 1-31 is in a vertical state, under the action of the elastic restoring force of the stage clip 1-32, the active force acting on the support rod 1-31 is vertically downward, acting on the first pressing plate 8, so that The first pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com