Cell factory pipeline system

A pipeline system and factory technology, applied in the field of cell culture, can solve the problems of reduced pressure of nutrient solution, less supply of nutrient solution in the culture tank, and reduced speed of supply of nutrient solution in the culture tank, etc., to ensure consistency and convenience. Ejection and replenishment operations, the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

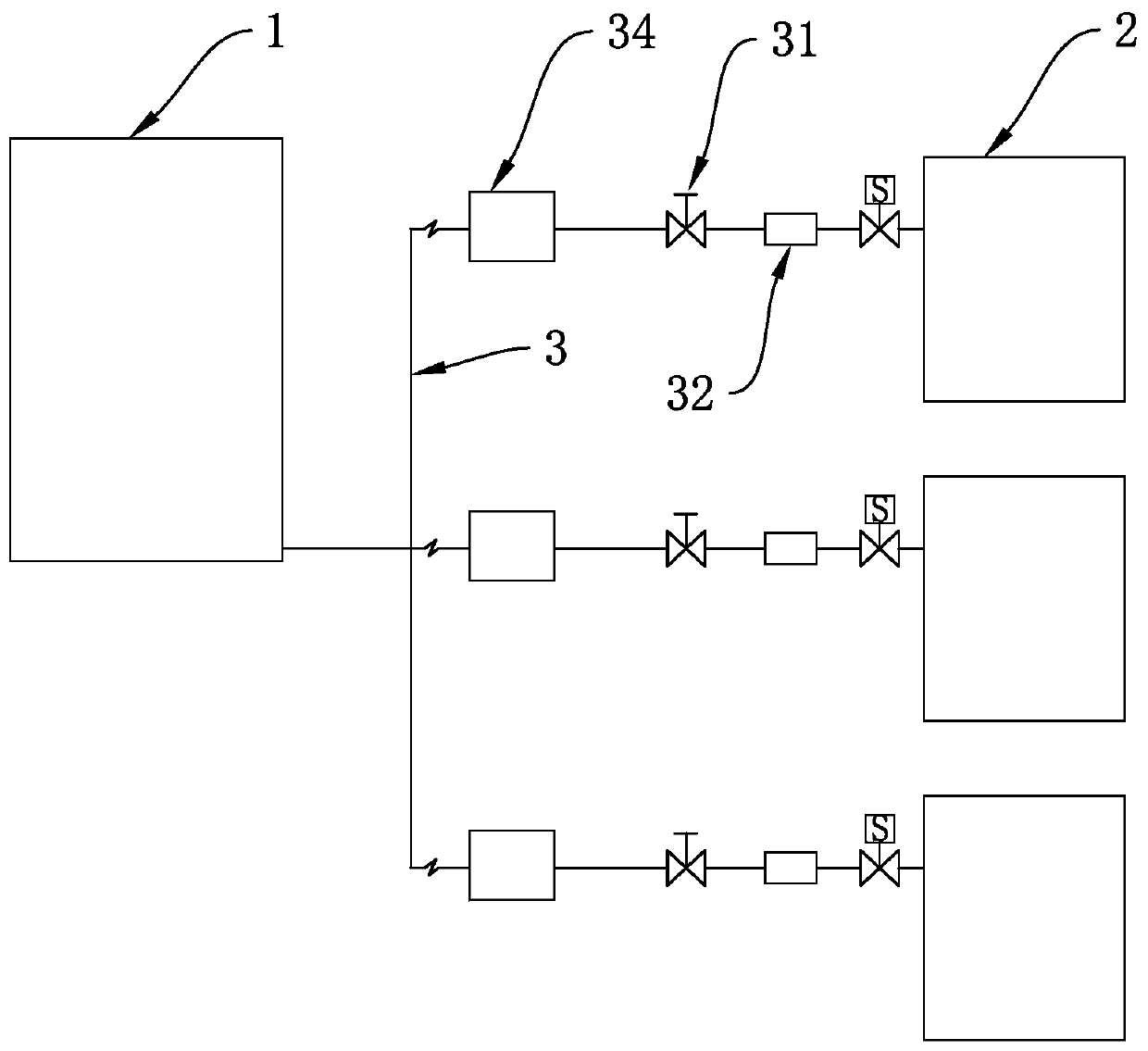

Method used

Image

Examples

Embodiment 2

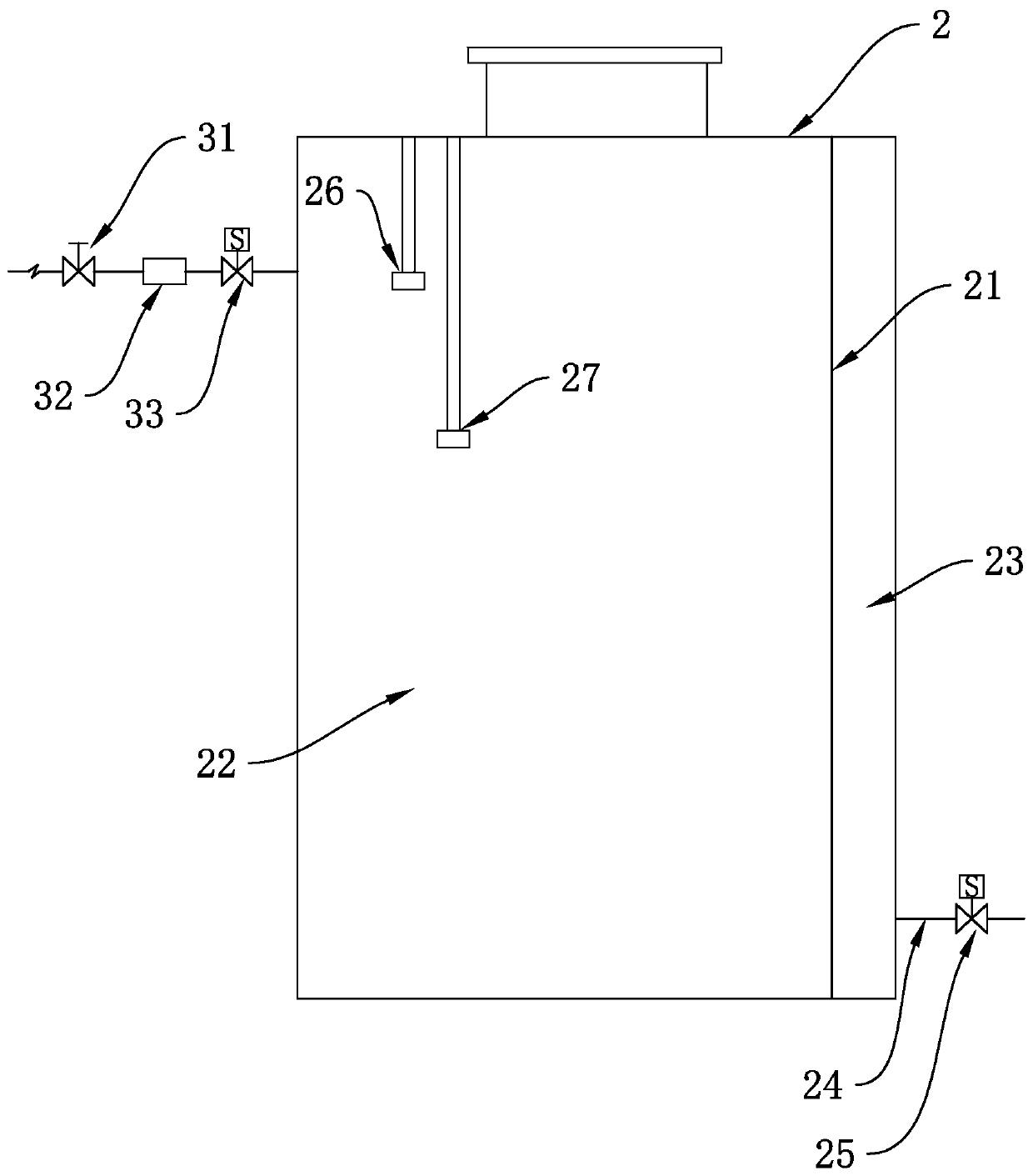

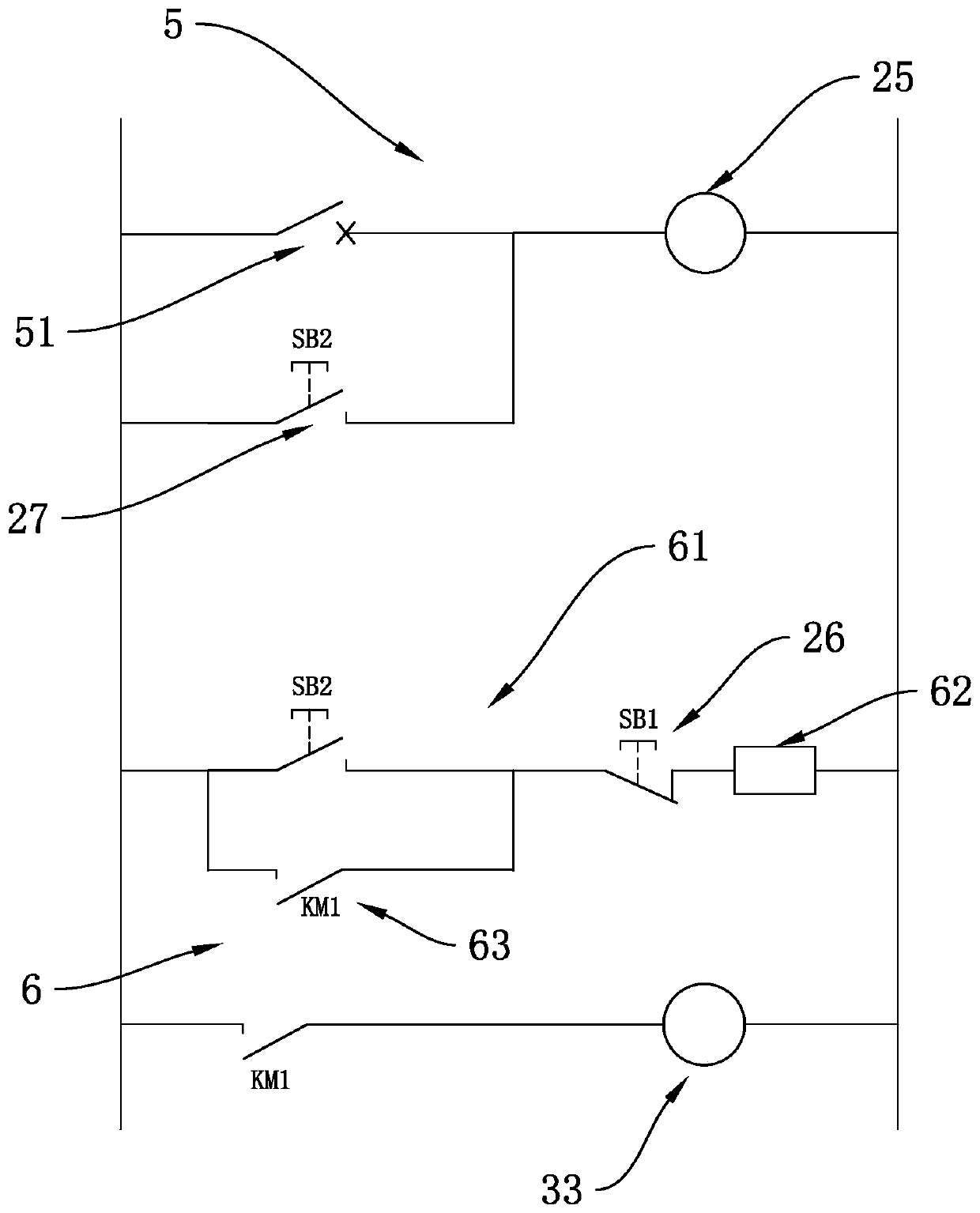

[0050] see Figure 5 , a cell factory piping system, the difference between it and Embodiment 1 is that a supply pump 7 is provided on the lower side of the liquid storage tank 1, and the suction port of the supply pump 7 communicates with the bottom of the liquid storage tank 1, and the supply pump 7 An infusion tube 71 is connected to the outlet of the liquid outlet, and any end of the supply pipe 3 that is connected to the culture tank 2 and away from the culture tank 2 is connected in parallel to the infusion tube 71 . In actual work, the supply pump 7 draws the nutrient solution in the liquid storage tank 1 and supplies it to the culture tank 2 through the supply pipe 3 .

[0051] The tank opening of the liquid storage tank 1 is sealed with a closing cover 8, and the upper part of the closing cover 8 is connected with a vent pipe 81, and the vent pipe 81 is provided with a third electromagnetic valve 82, and the end of the vent pipe 81 away from the closing cap 8 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com