Performance optimization nylon zipper forming machine

A molding machine, nylon technology, applied in the direction of sliding fastener elements, applications, fasteners, etc., can solve the problems of increased resistance, low speed efficiency, monofilament wear, etc., to improve the damping effect, prolong the service life, and ensure stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with the accompanying drawings and specific examples for further description

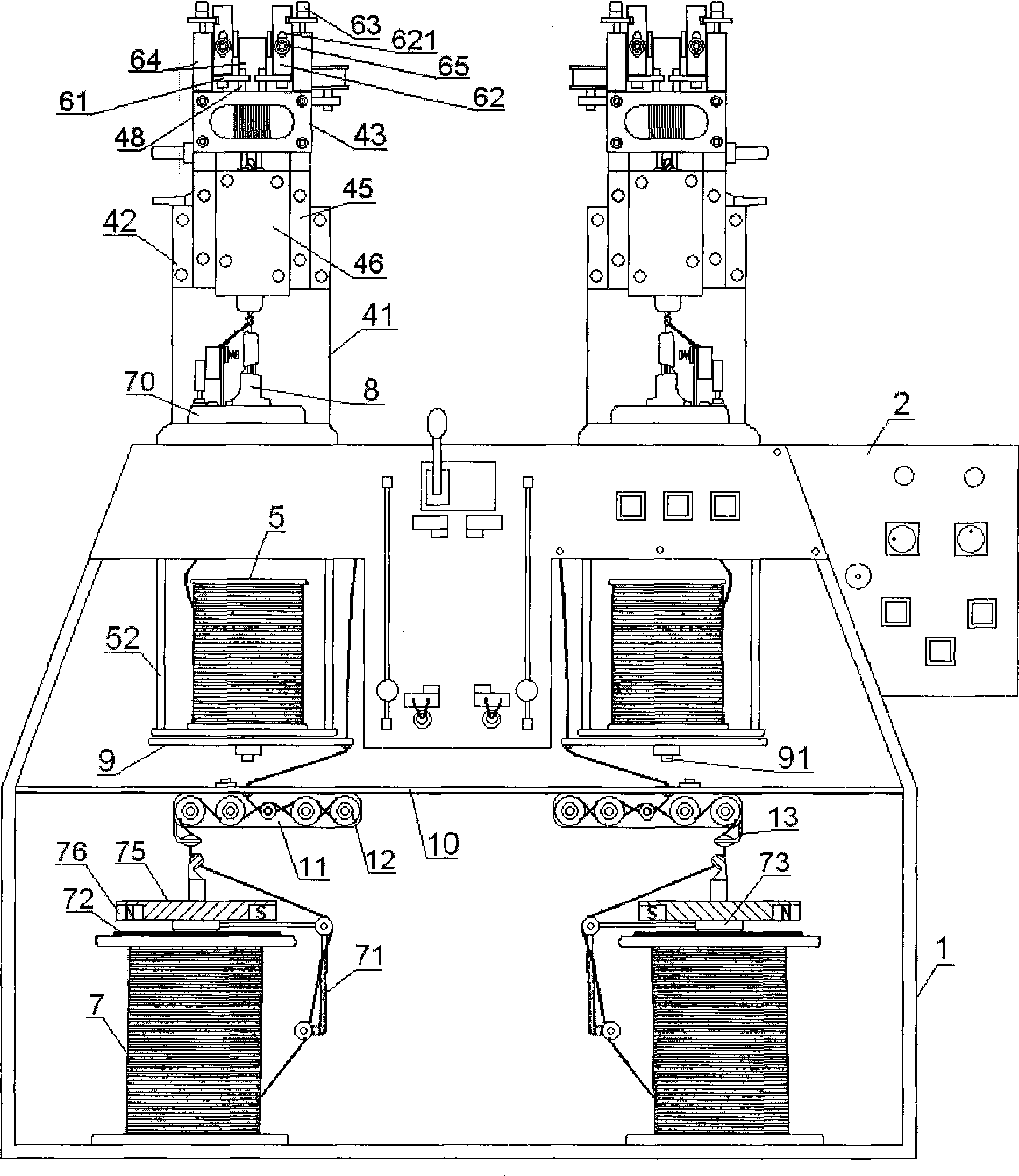

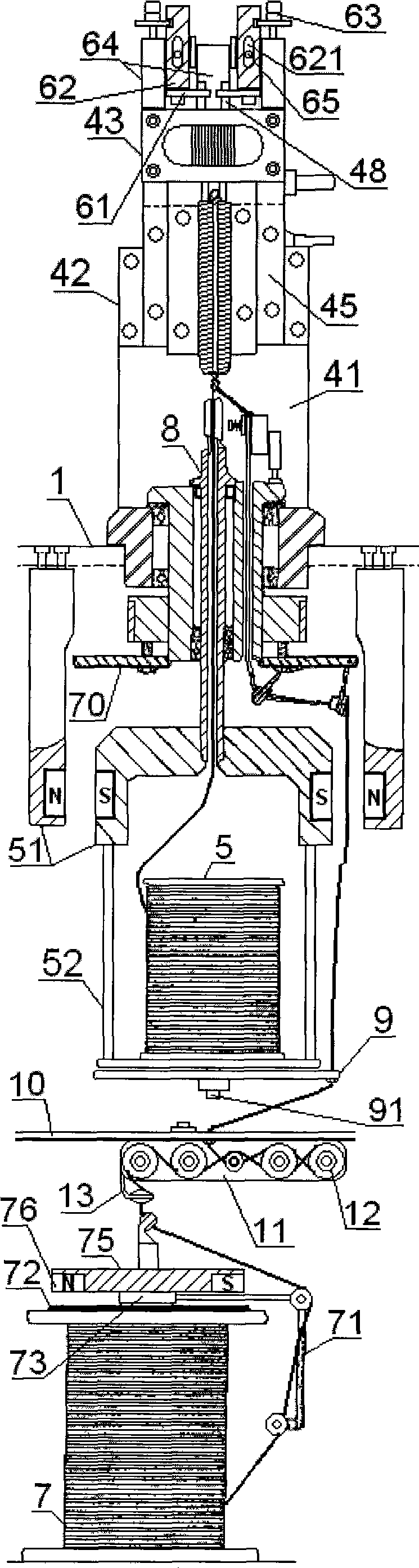

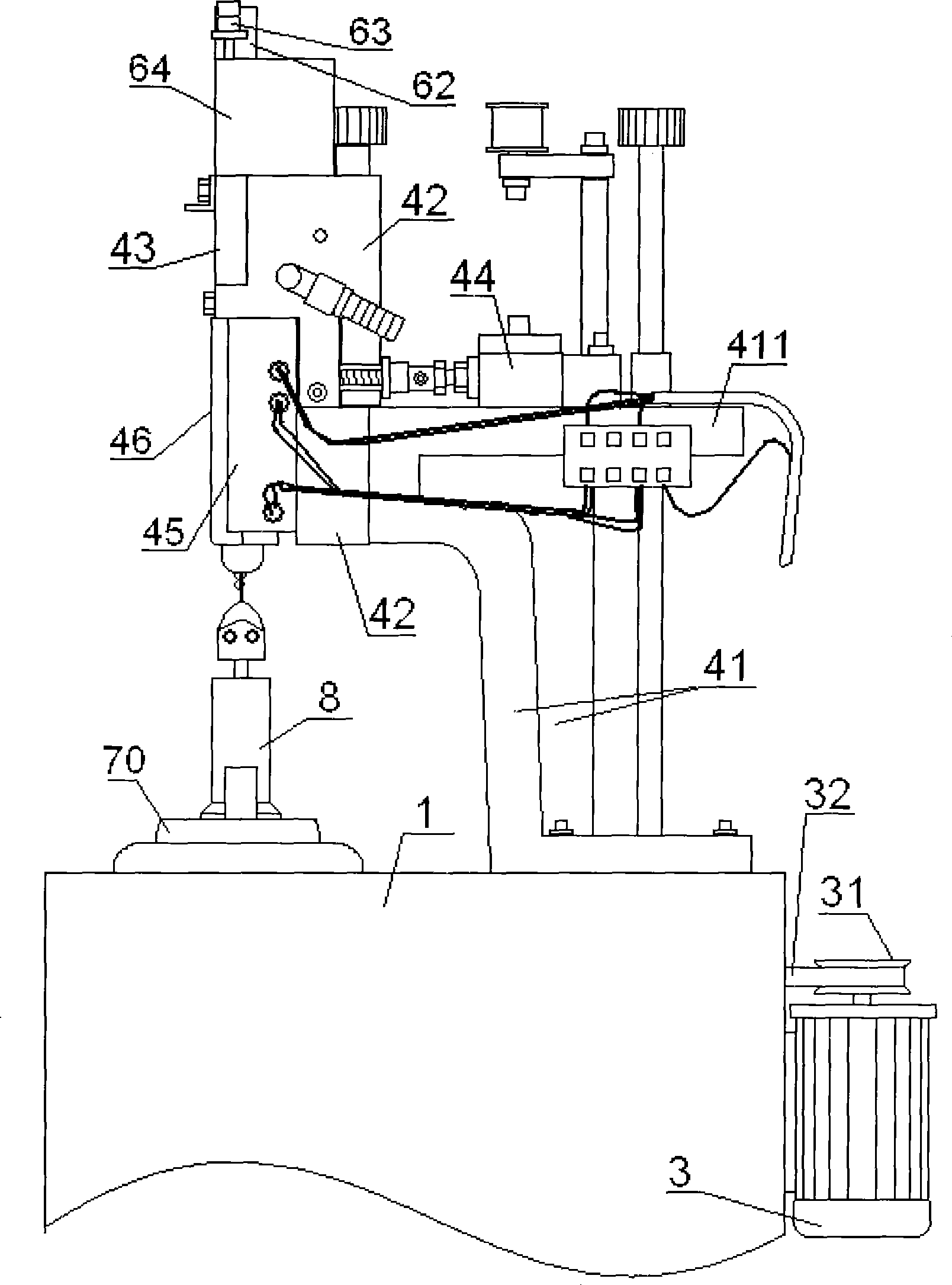

[0022] As shown in the figure, the performance-optimized nylon zipper forming machine of the present invention includes a frame 1 whose upper part is a small trapezoidal shape, an electric control box 2 mounted on one side of the upper part of the frame 1, a motor 3, and a motor 3 installed on the frame 1. The molding device above drives the two parallel main shafts of the molding device, and the feeding device installed in the frame 1 drives the two parallel auxiliary shafts of the feeding device. The molding device comprises a support frame 41 with a top plate 411 fixed on the top of the frame 1 arranged side by side, and an inverted T-shaped support plate 42 fixed on the front end of the frame top plate 411; the inverted T-shaped support plate 42 top surface is fixed with The upper and lower position adjustment mechanism of the forming screw, the forming screw drive me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com