Smoke cartridge assembly and electronic cigarette

A technology of components and pods, applied in the field of electronic cigarettes, can solve the problem of not being able to know the opening degree of the oil inlet of the cotton wick from the outside world

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

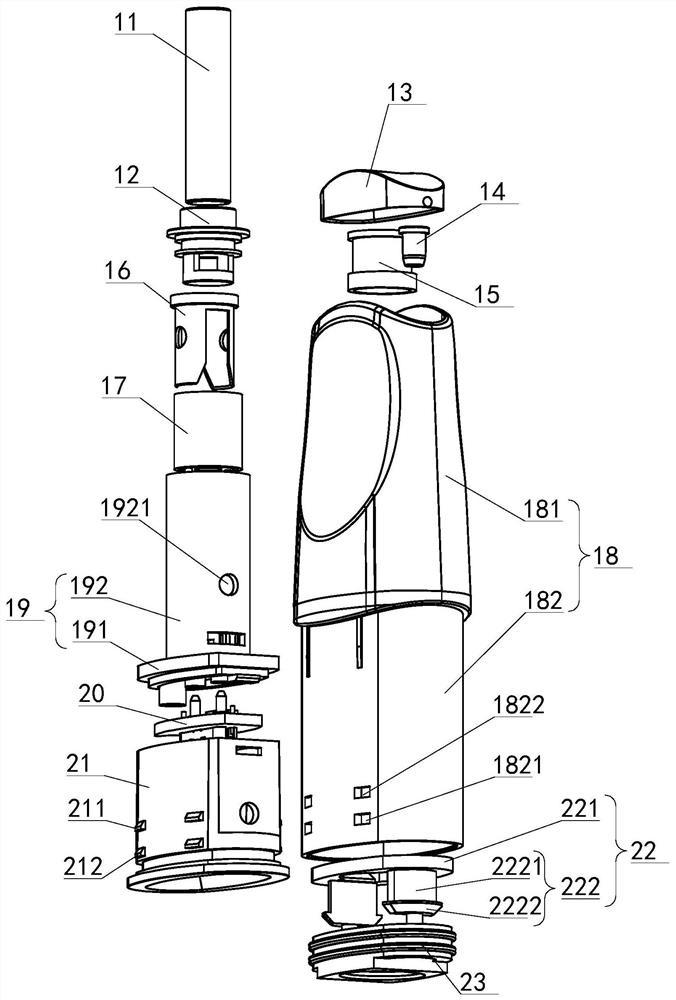

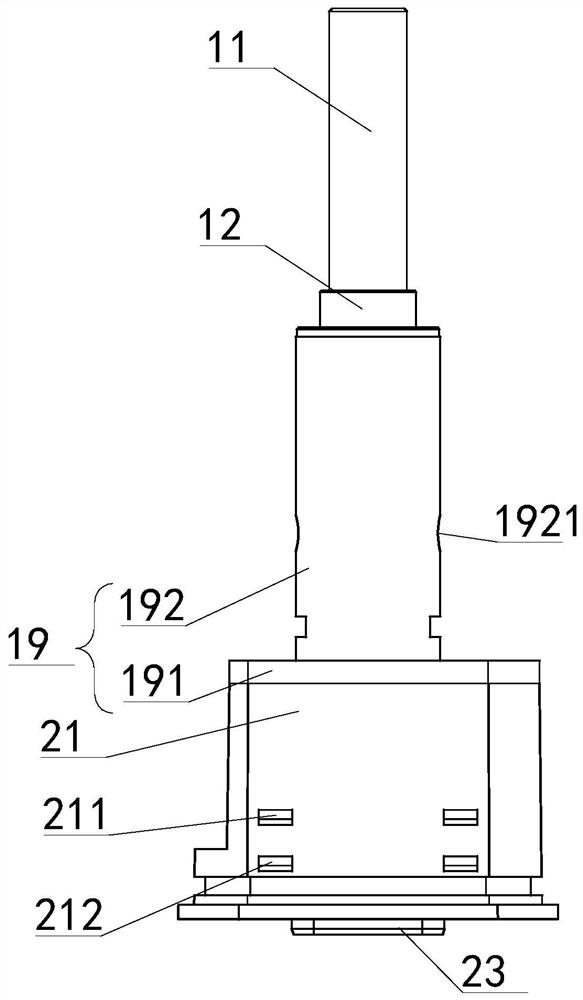

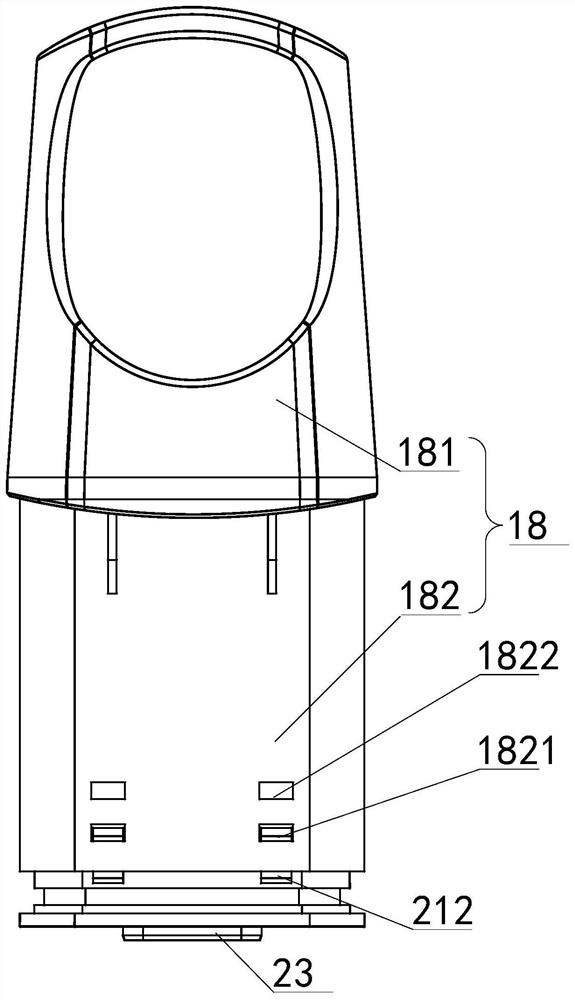

[0043] Such as Figure 1-Figure 7 As shown, this embodiment provides a pod assembly, including an atomizing core 17, an atomizing core mounting assembly and an oil cup 18, the atomizing core 17 is installed in the atomizing core mounting assembly, and the atomizing core mounting assembly is provided with The oil inlet hole 1921 and the positioning protrusion, the positioning protrusion includes the first category positioning protrusion 211, the oil cup 18 includes the oil storage part 181 and the sliding base 182, the oil storage part 181 is used to form the oil storage cavity, and the sliding base 182 is used to slide relative to the atomizing core installation assembly. The sliding base 182 is provided with a first category positioning hole 1821 and a second category positioning hole 1822, and the first category positioning hole 1821 and the second category positioning hole 1822 both pass through the oil cup 18 side walls;

[0044] The atomizing core mounting assembly has a...

Embodiment 2

[0063] Such as Figure 7 to Figure 9 As shown, the electronic cigarette provided in this embodiment includes the cartridge assembly in any one of the foregoing embodiments.

[0064] Since the electronic cigarette provided by this embodiment includes any one of the above-mentioned cartridge components, it has the technical effect of any one of the above-mentioned cartridge components, and will not be repeated here.

[0065] In an optional embodiment, it also includes a battery 34 assembly, the battery 34 assembly includes a battery assembly housing 37 and a battery holder 36, the battery holder 36 is installed in the battery assembly housing 37, and the battery holder 36 and the battery assembly housing 37 There is a bracket sealing ring 35 and a battery bracket 36 on which a battery 34 and a main board 33 are installed, and the battery 34 is electrically connected to the main board 33; connect. A lamp cover 38 is also provided at the bottom of the battery pack housing 37 . ...

Embodiment 3

[0068] Such as Figure 10-Figure 13 As shown, this embodiment also provides a cartridge assembly. The cartridge assembly of this embodiment is an improvement on the basis of Embodiment 1, and the technical solution of Embodiment 1 also belongs to this embodiment. The description will not be repeated here. The same components use the same reference numerals as in the first embodiment, and reference is made to the description of the first embodiment. If a reference sign appears in the drawings used in this embodiment but does not appear in the text of this embodiment, you can refer to the description of the reference sign in Embodiment 1. If a reference sign appears in the text used in this embodiment but does not appear in the drawings of this embodiment, you can refer to the drawings used in Embodiment 1 to assist in understanding the content shown by the reference sign.

[0069] The pod assembly in this embodiment uses a horizontal core pod assembly. Specifically, the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com