Feed dryer

A dryer and feed technology, applied in the direction of progressive dryer, drying of solid materials, drying, etc., can solve the problems of long drying time and low heat transfer efficiency, so as to improve the effect, improve the efficiency of heating, and improve the efficiency of heating. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

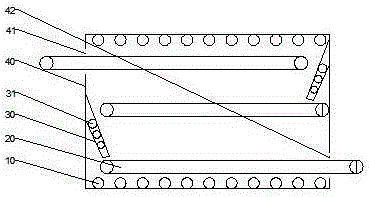

[0016] like figure 1 As shown, the scheme of the feed dryer is as follows: it includes a box body 40 and a horizontally arranged conveyor belt 20 , the upper part of the box body 40 is provided with a feed port 41 , and the lower part of the box body 40 is provided with a discharge port 42 . The conveyor belt 20 is located inside the box body 40 . The conveyor belt 20 is multi-layered and arranged in parallel. One end of the uppermost conveyor belt stretches out of the feed port 41 , and one end of the bottom conveyor belt stretches out of the discharge port 42 . A baffle 30 is arranged between the output end of the conveyor belt and the input end of the lower conveyor belt. The baffle 30 is obliquely arranged on the box body 40. A heating pipe 31 is arranged in the baffle plate 30. The top surface and the bottom surface of the inner wall of the box body 40 A heat pipe 10 is provided.

[0017] In addition, in this embodiment, the conveyor belt 20 has at least three layers. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com