Material storage device for pipe color master batch production

A color masterbatch and material storage technology, applied in the field of color masterbatch, can solve problems such as oxidation, agglomeration, and reduction of the appearance and quality of color masterbatch pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

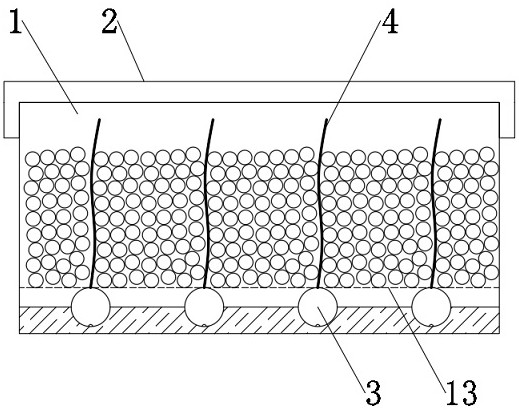

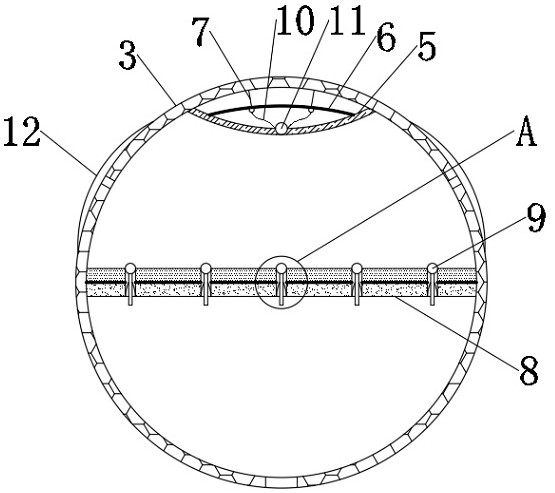

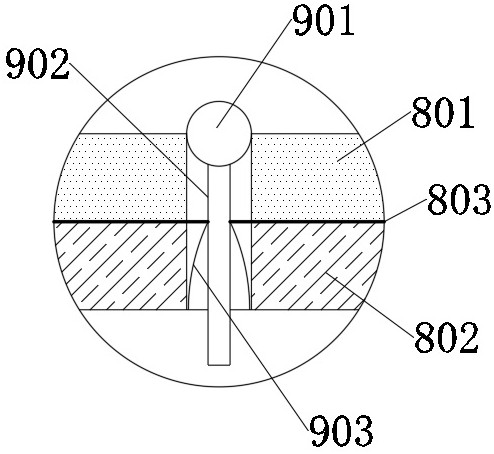

[0039] See Figure 1-2 A storage device for tube color masterbatch produced, including a storage tank 1, a matching sealed storage cover 2 on the storage case 1, and a plurality of uniform distributions are opened in the bottom end of the storage case 1. The stable semi-spherical groove, the active mosaic active ball in the stable hemispherion has a matchable ball 3, the upper end of the active ball 3 is connected to the absorbent shaft 4, the lower end of the active ball 3 is opened, and the gas storage box 1 is connected to the gas The mesh plate 13, and the absorbent shaft 4 penetrates the tape sheet 13 and extends to the upper side thereof, and the top end of the active ball 3 is attached to the top of the tank 5, and the upper side of the collecting sheet 5 is provided with a migration piece 6, and moisturious vertical The wire 4 penetrates the upper end of the movable ball 3 and is connected to the upper end of the migration piece 6, and the migration piece 6 is connected bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com