Roller capable of simultaneously drying and heating reclaimed material and new aggregate

A technology for drying and heating new aggregates, which is applied in the directions of roads, road repairs, roads, etc., can solve the problem of unsolved asphalt aging, etc., and achieves the effects of good heating and drying effect, simple production and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

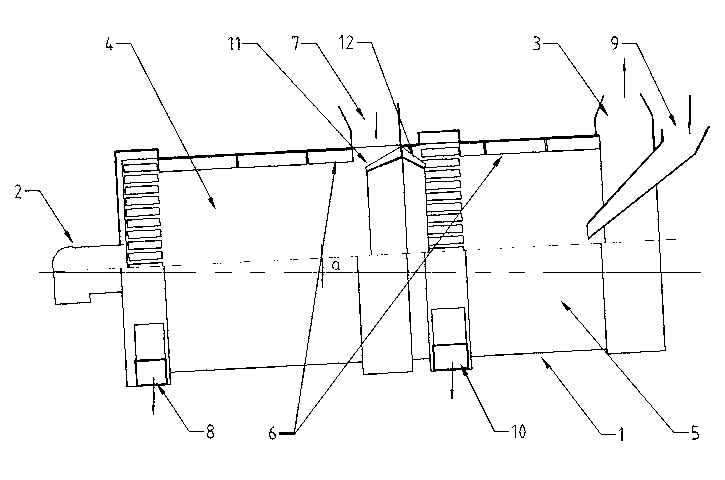

[0016] Such as figure 1 As shown, the present invention includes a new aggregate drying heating zone 4 and a recycled material drying heating zone 5 .

[0017] The new aggregate drying heating area 4 is composed of the new aggregate inlet 7, the drum 1, the new aggregate outlet 8, the hollow material guide cone 11, and the turning blade 6. There is a burner 2 on the end surface of the drum 1; to realize the new The aggregate is dried and heated to a certain high temperature.

[0018] Recycled material drying heating area 5 is composed of hollow material retaining cone 12, recycled material outlet 10, turning blade 6, and recycled material inlet 9, which realizes drying moisture of recycled material and heating to a certain high temperature.

[0019] The smoke box 3 is the smoke collection and exhaust passage of the drying heating drum.

[0020] New aggregates and recycled aggregates after drying and heating have their own outlets and cannot be mixed.

[0021] The drum 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com