Sludge moisture content control device and moisture content adjustment method

A control device and technology of moisture content, applied in water treatment parameter control, water/sludge/sewage treatment, chemical instruments and methods, etc. The size of the dryer is not controlled, so as to achieve the effect of high industrial use value, good drying effect and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

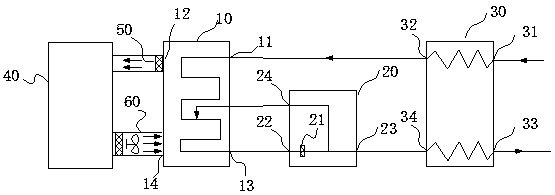

[0033] Such as figure 1 As shown, this embodiment provides a sludge moisture content control device, including a drying device 10 that heats and removes water from the sludge, and is characterized in that it also includes a detection device 20 that performs online detection of the sludge moisture content. One side of the drying device 10 is provided with a high temperature dry air inlet 14 and a low temperature non-drying air outlet 12, and the other side is provided with a low temperature non-drying sludge inlet 11, a high temperature dry sludge outlet 13 and a sludge recovery inlet, so that the sludge The flow direction in the drying device 10 is opposite to that of air; the detection device 20 is arranged in the direction of the high-temperature dried sludge outlet 13 of the drying device 10, and the detection device 20 includes a detection inlet 22 communicating with the high-temperature dried sludge outlet 13 and qualified The sludge outlet 23 and the unqualified sludge ou...

Embodiment 2

[0047] A sludge moisture content control device includes a drying device 10 for heating and removing water from the sludge. It is characterized in that it also includes a detection device 20 for online detection of the sludge moisture content. One side of the drying device 10 is provided There are a high temperature dry air inlet 14 and a low temperature non-dried air outlet 12, and the other side is provided with a low temperature non-dried sludge inlet 11, a high temperature dry sludge outlet 13 and a sludge recovery inlet, so that the flow direction of the sludge in the drying device 10 is The air is opposite; the detection device 20 is arranged in the direction of the high-temperature dried sludge outlet 13 of the drying device 10, and the detection device 20 includes a detection inlet 22 communicating with the high-temperature dried sludge outlet 13, a qualified sludge outlet 23, and unqualified sludge Sludge outlet 24. The unqualified sludge outlet 24 is in communication w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com