Foundry sand incremental fast-drying equipment based on iron piece

A fast drying, progressive technology, applied in the preliminary treatment of promoting solid material drying, drying solid material, granular material drying, etc., can solve the problems of wear, inconvenient heat dissipation of sand body, sand fog, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

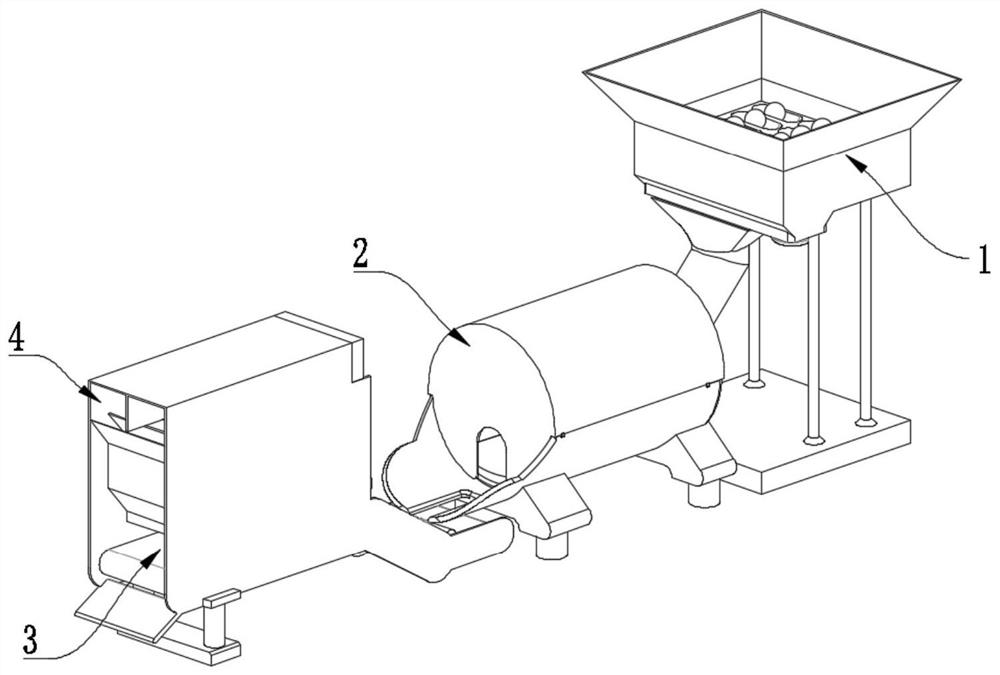

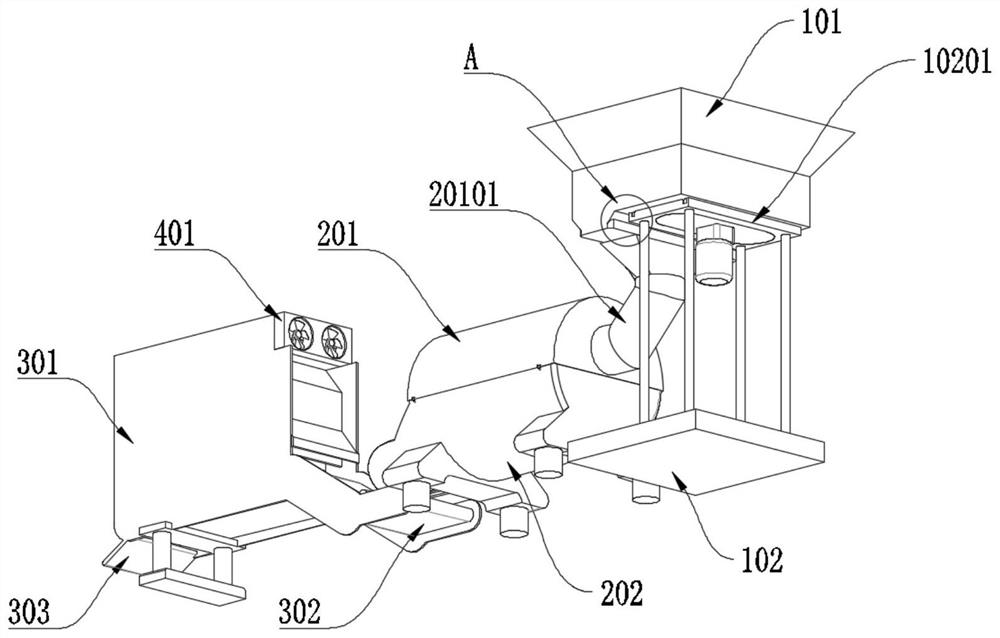

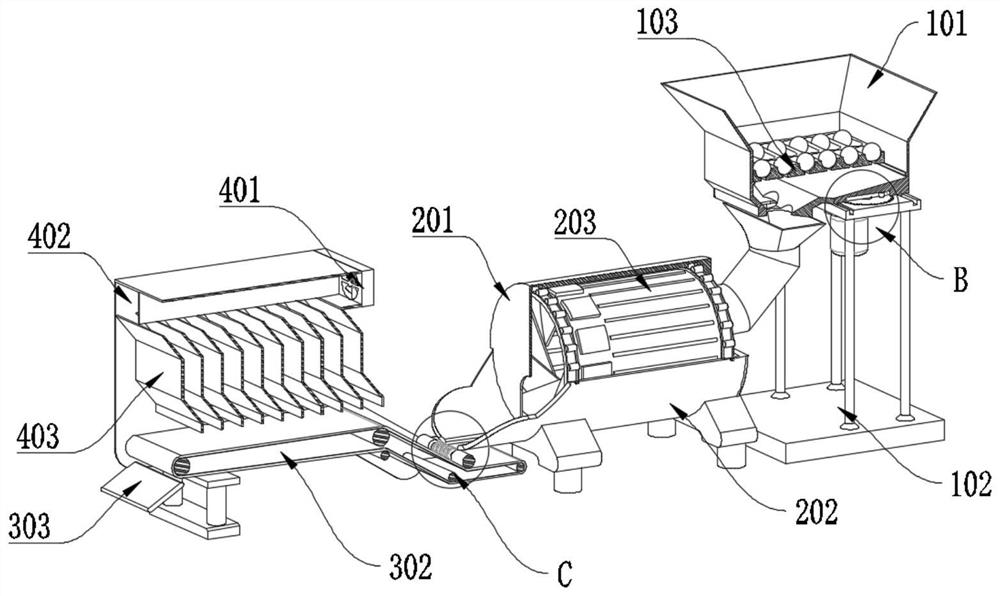

[0035] as attached figure 1 To attach Figure 9 Shown:

[0036] The invention provides a progressive rapid drying equipment for casting sand based on iron parts, which includes a feeding structure 1; The top of the structure 3 is provided with a cooling structure 4; the feeding structure 1 includes a feed trough 101, a support plate 102, a mounting plate 10201, a support column 10202, and a discharge trough 104, and the feed trough 101 is directly installed on the top of the support plate 102 , four vertical support columns 10202 are fixed on the support plate 102, and the top of the four support columns 10202 is fixed with a mounting plate 10201. Sliding to the slope of the discharge chute 104, the four support columns 10202 on the support plate 102 will support the installation plate 10201, and the four support columns 10202 can support the installation plate 10201 more stably. The bottom of the front end of the feed chute 101 is the discharge trough 104, and the bottom sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com