Non-polluting environment-friendly feed system

A non-polluting and environmentally friendly technology, applied in the fields of feed, food science, application, etc., can solve the problems of low utilization rate of heating and drying energy, insufficient coordination, complex structure, etc., and achieve good heating and drying effect, simplicity and compactness, and energy utilization. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is further described in conjunction with the following examples.

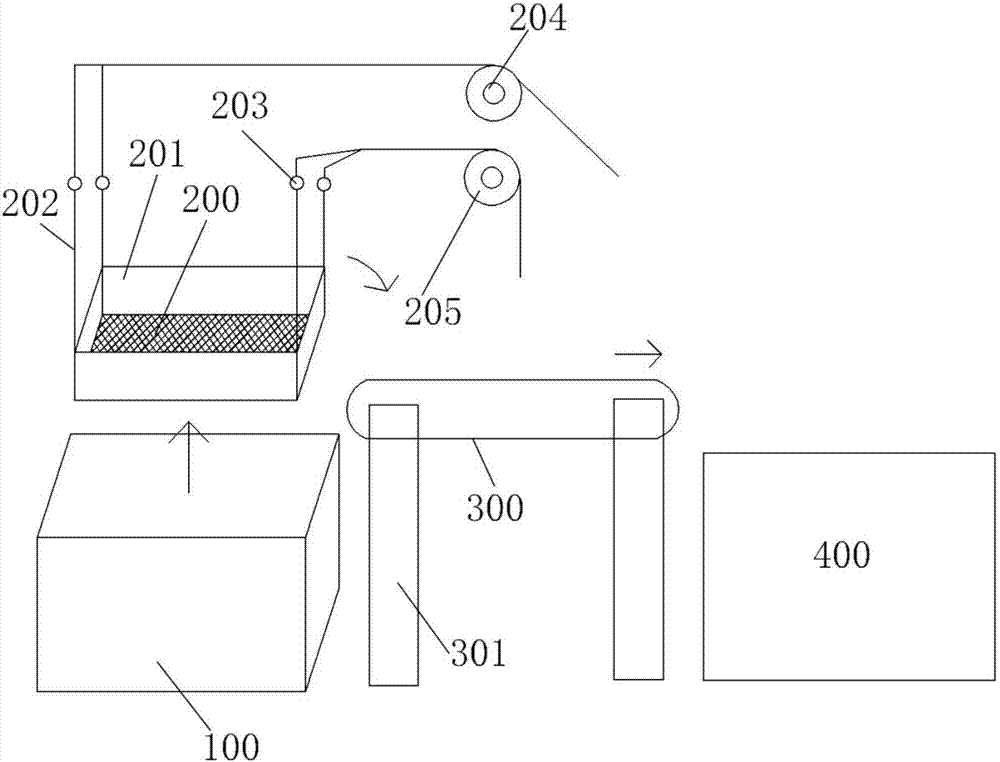

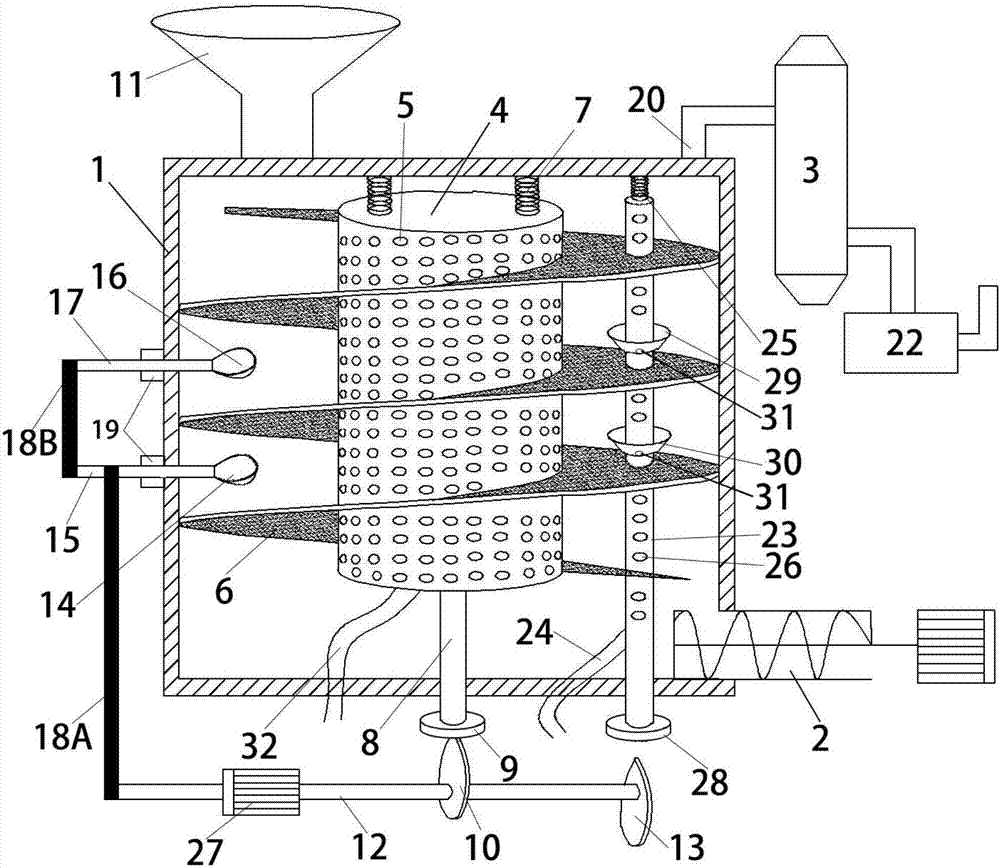

[0012] See eg Figure 1-2 A kind of pollution-free environment-friendly feed system shown, comprises fermenting vat 100, filter screen 200, conveyor belt 300 and heating and drying device 400, square filter screen 200 has 4 protruding edge plates 201, 4 edge plate 201 The corners are connected with suspension rings 203 through steel wires 202, the left two suspension rings are wound on the first pulley 204 through a common steel wire, and the right two suspension rings are wound on the second pulley 205 through a common steel wire; the conveyor belt 300 passes through the bracket 301 stands on the right side of the fermentation tank 100 , and the heating and drying device 400 is located on the right side of the conveyor belt 300 .

[0013] As a further preferred solution, the filter screen 200 is placed in the fermenter 100. After the fermentation of the feed material in the fermen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com