Straw drying device utilizing induction heating and provided with double heating structures

A dual heating and induction heating technology, applied in heating devices, drying, dryers, etc., can solve the problems of insufficient drying effect, slow drying speed of straw, and rising temperature of heating plate, etc., to facilitate heating and drying. , good effect, large heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

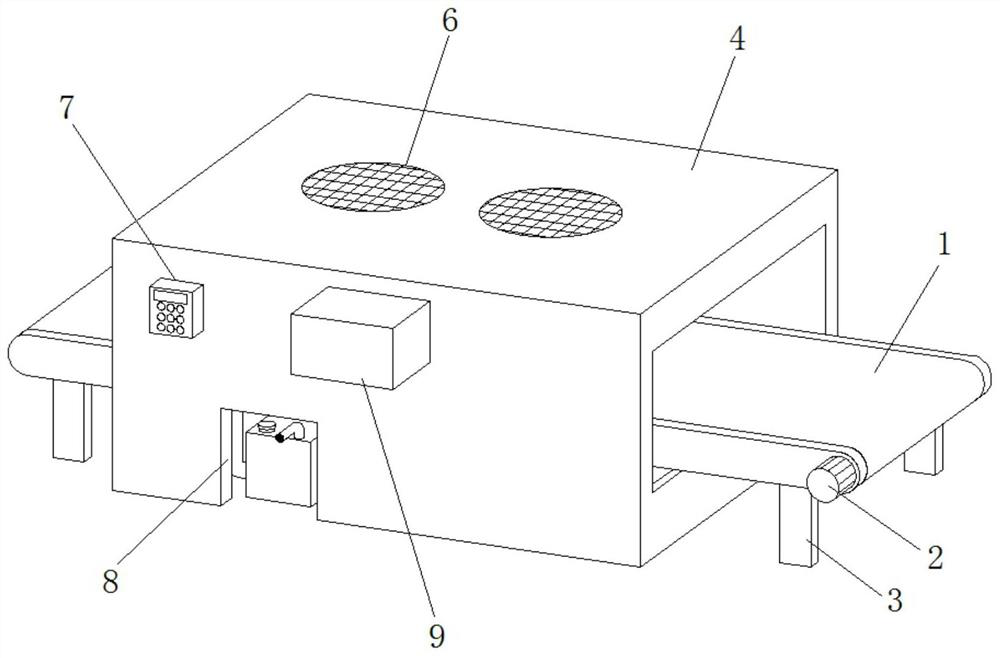

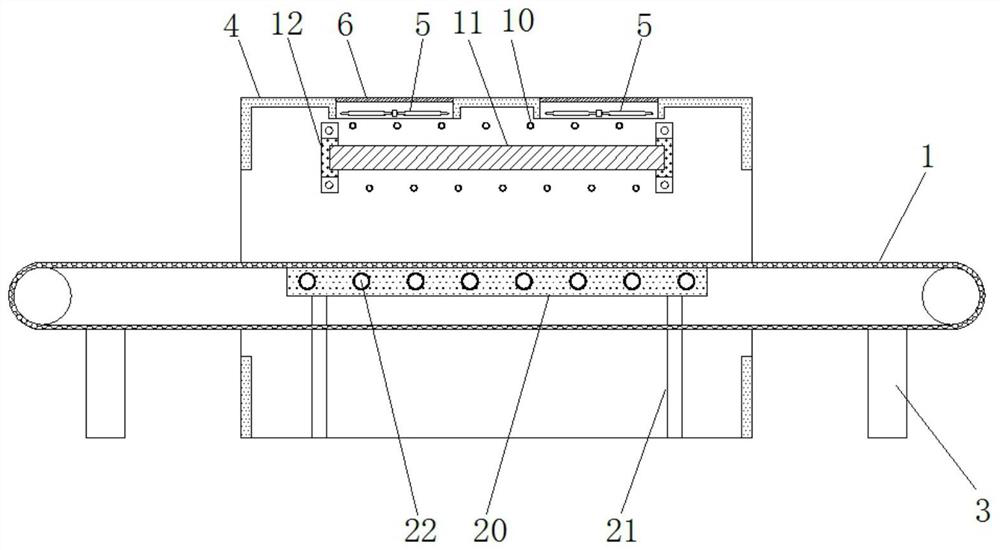

[0029] see Figure 1-3 , a straw drying device with a double heating structure using induction heating, comprising a conveyor belt mechanism 1 driven by a servo motor 2 fixedly installed on the right end side wall of the conveyor belt mechanism 1, the conveyor The lower surfaces of both ends of the belt mechanism 1 are fixedly equipped with a first support frame 3, and a protective cover 4 is arranged outside the middle position of the conveyor belt mechanism 1, and the top of the protective cover 4 is uniform along the length direction of the conveyor belt mechanism 1. Two fans 5 are fixedly installed, and a filter screen 6 is fixedly installed on the upper surfaces of the two fans 5, a control switch 7 is fixedly installed on the front left upper end of the protective cover 4, and a front lower end of the protective cover 4 is opened. There is a water tank mouth 8, and a low-frequency power supply 9 is fixedly installed in the middle position of the front upper end of the pr...

Embodiment example 2

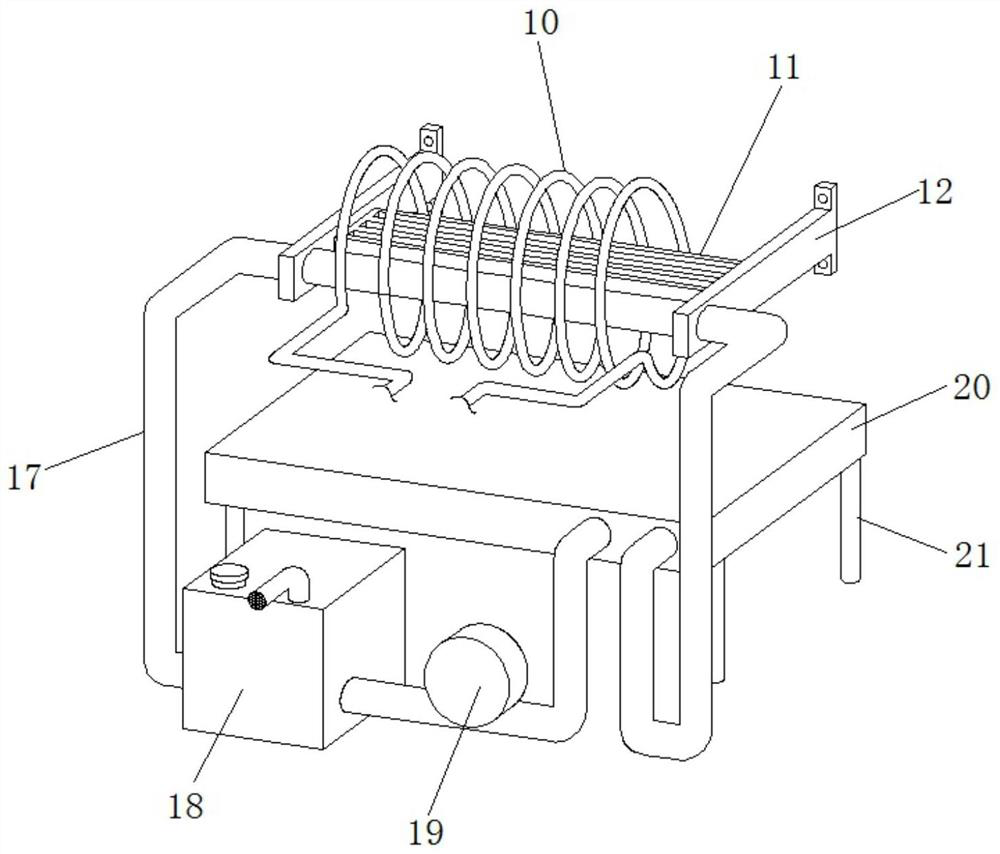

[0034] see Figure 5The circulation heating mechanism 13 includes a heating copper tube 16 fixedly installed on the outer ends of the two ceramic fixing frames 12 and arranged in the induction hollow copper tube coil 10 along the length direction of the conveyor belt mechanism 1. The heating copper tube 16 is The left end communicates with the water storage tank 18 , the water pump 19 and the heating plate 20 through the connecting copper pipe 17 in turn, and the heating plate 20 communicates with the right end of the heating copper pipe 16 through the connecting copper pipe 17 .

[0035] The heating copper pipe 16 of the circulating heating mechanism 13 can heat the water inside the heating copper pipe 16 under the induction heating effect of the induction hollow copper pipe coil 10 after electrification, and the heated water can circulate through the water under the circulation action of the water pump 19. The heating plate 20 is used to heat and dry the straw at the bottom....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com