Swing type raw material drying device for food processing

A food processing and drying device technology, applied in drying, dryer, drying gas arrangement and other directions, can solve problems such as unfavorable food preservation and use, inability to completely dry, limited stirring range, etc., to improve the heating and drying effect , Avoid the dead angle of heating, improve the effect of flipping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

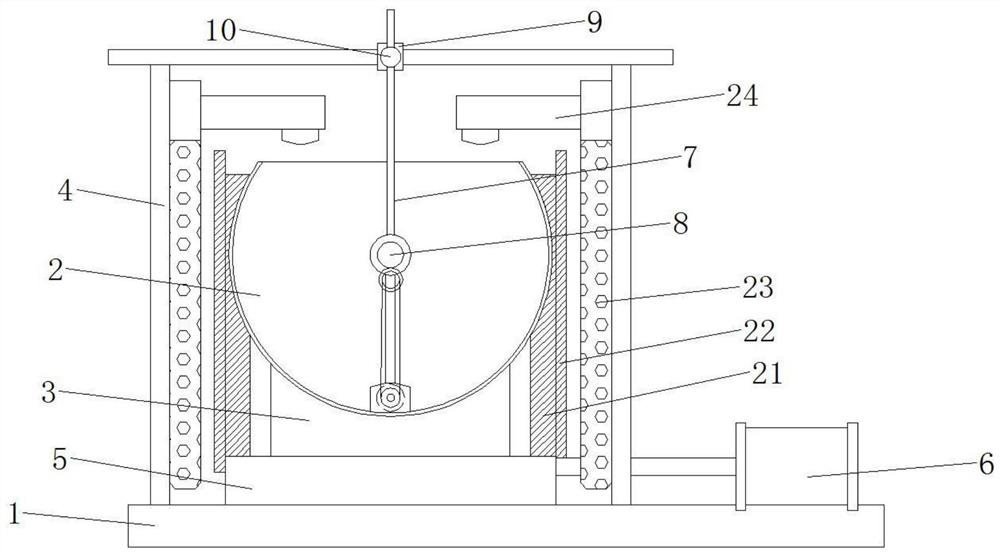

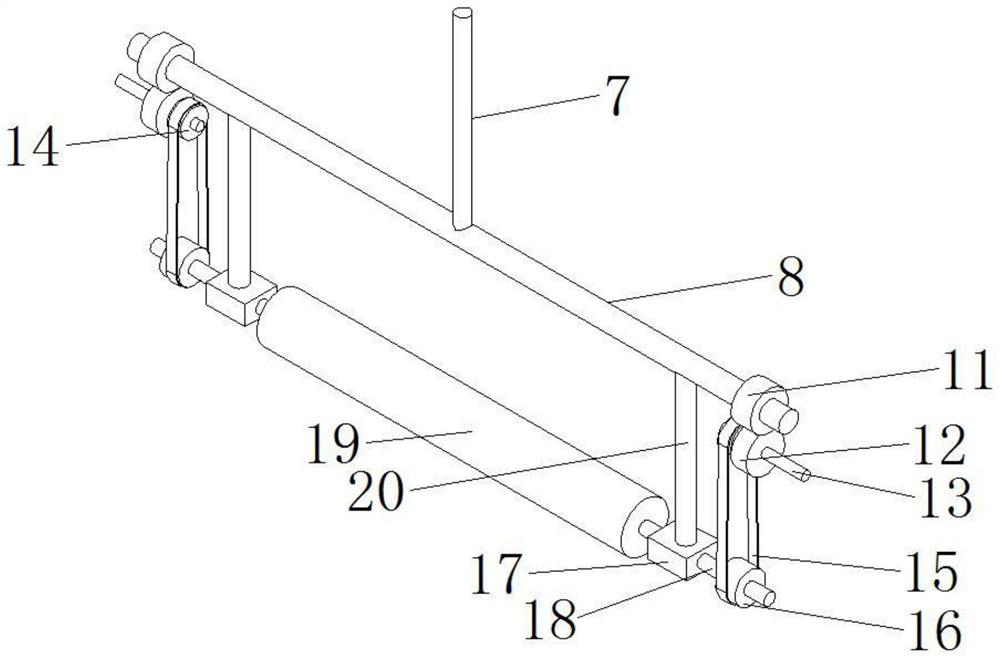

[0021] Please refer to the figure, in the embodiment of the present invention, a swing-type raw material drying device for food processing includes a base 1, a drying cylinder 2, a heating cover 3 and a bracket 4; the base 1 is arranged horizontally, and the bracket 4 is a gantry structure , fixed on the base 1, a horizontal drying cylinder 2 is arranged inside the bracket 4, the opening of the drying cylinder 2 faces upward, and the food to be dried is loaded from the top of the drying cylinder 2, and the drying cylinder 2 is in the The inside of the bracket 4 moves left and right, the bottom of the drying cylinder 2 is fixedly connected with a heating cover 3, and a heating element is arranged in the heating cover 3, and the heating cover 3 heats the inside of the drying cylinder 2 to increase the temperature of the food so that the inside Moisture evaporates, and the lower side of the heating cover 3 is fixedly provided with a sliding seat 5, which is slidably connected to t...

Embodiment 2

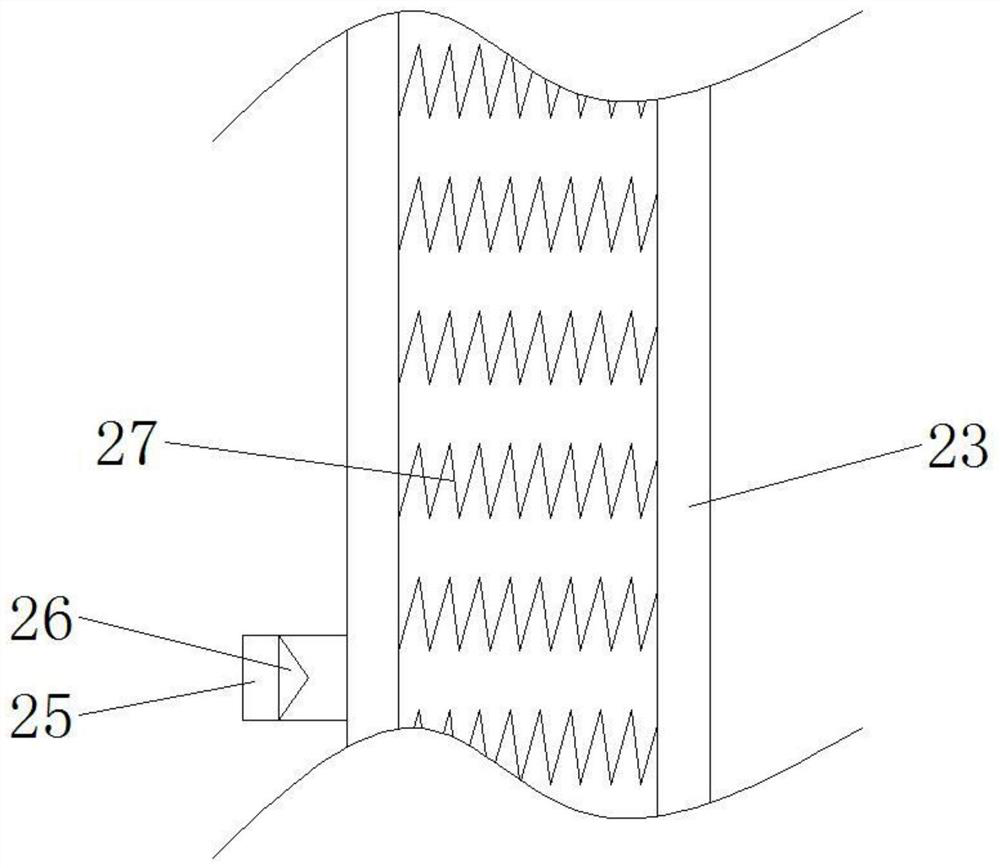

[0024] On the basis of Embodiment 1, vertical airbags 23 are fixedly installed on both sides of the support 4. The inside of the airbag 23 is a sealed structure. The airbag 23 is connected with an air inlet pipe 25, and the air inlet pipe 25 is equipped with a One-way valve 26 makes outside air enter in air bag 23 from air inlet pipe 25, and a plurality of horizontal support springs 27 are evenly installed in air bag 23, support air bag 23 by support spring 27, make it keep expanding; The upper end of the airbag 23 is communicated with a blowing pipe 24 located above the drying cylinder 2, and a check valve 26 is also arranged in the blowing pipe 24, so that the air in the air bag 23 is blown out from the blowing pipe 24, and the end of the blowing pipe 24 is provided with a vertical The straight downward blowing nozzle blows air into the drying cylinder 2, and blows out the water vapor generated inside to improve the fluidity of the internal air; on the left and right sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com