Preparation method of highly fragrant black tea

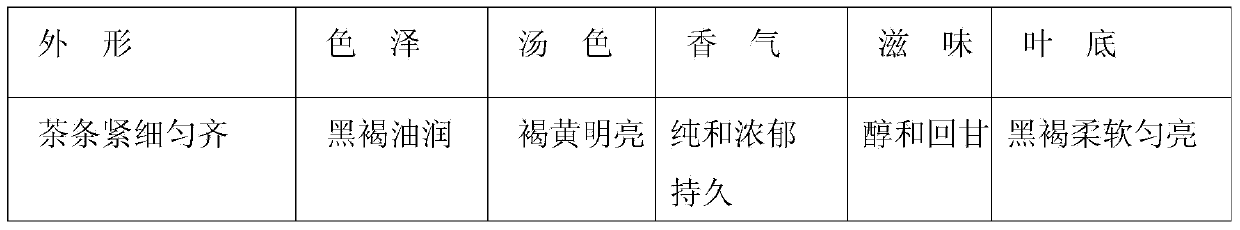

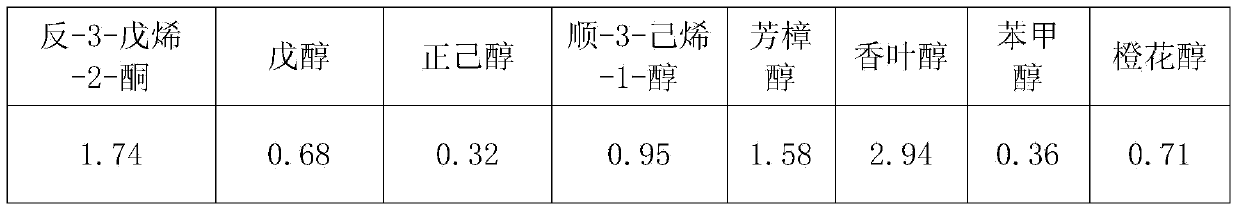

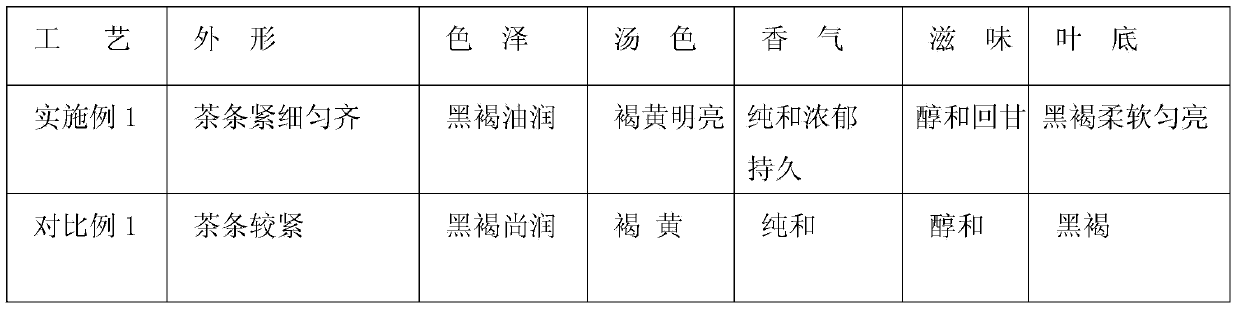

A high-flavor, black tea technology, applied in tea treatment before extraction, etc., can solve the problems of not strong and long-lasting aroma, uneven shape, etc., achieve the effect of pure and strong aroma, mellow taste and sweet aftertaste, and promote full transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Picking of fresh leaves: fresh leaves are picked from Fuding Dabai tea, Mingxuan 131, Mingxuan 311 and other fine varieties of tea trees. . The weight of fresh tea leaves is 4600 kg.

[0038] 2. Spreading: fresh leaves are spread in a ventilated, clean and dry green booth with a thickness of 5cm to 10cm. The indoor temperature can be controlled at 17-25°C by air-conditioning equipment, and the relative humidity can be controlled at 50% by a dehumidifier. -65%, then use an exhaust fan to exchange the air in the booth to dehydrate it moderately. The spreading time is 4 to 7 hours, and the water content in the fresh leaves is controlled at 60% to 68% after spreading.

[0039] 3. Finishing: use a drum continuous killing machine (ST100Q type) to finish, the speed is 25-35 rpm, the temperature is controlled at 200-300°C, and the finishing time is 4-8 minutes. After finishing, the water content of the tea leaves is controlled at 55%. ~ 63%, after the leaves are delivered...

Embodiment 2

[0047] 1. Picking of fresh leaves: fresh leaves are picked from Fuding Dabai tea, Mingxuan 131, Mingxuan 311 and other fine varieties of tea trees. . The weight of fresh tea leaves is 5000 kg.

[0048] 2. Spreading: fresh leaves are spread in a ventilated, clean and dry green booth with a thickness of 5cm to 10cm. The indoor temperature can be controlled at 18-24°C by air-conditioning equipment, and the relative humidity can be controlled at 50% by a dehumidifier. -65%, then use an exhaust fan to exchange the air in the booth to dehydrate it moderately. The spreading time is 4 to 7 hours, and the water content in the fresh leaves is controlled at 60% to 66% after spreading.

[0049] 3. Finishing: use a drum continuous killing machine (ST100Q type) to finish, the speed is 25-35 rpm, the temperature is controlled at 200-290°C, and the finishing time is 4-8 minutes. After finishing, the water content of the tea leaves is controlled at 55%. ~ 62%, after the leaves are delivered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com