Walnut processing technology and whole set of processing equipment

A processing equipment and walnut technology, applied in food preparation, food processing, pod removal, etc., can solve the problems of low productivity, long time-consuming and high cost of walnut shell and kernel, and achieve high productivity, shorten the time for removing green skin, and improve productivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

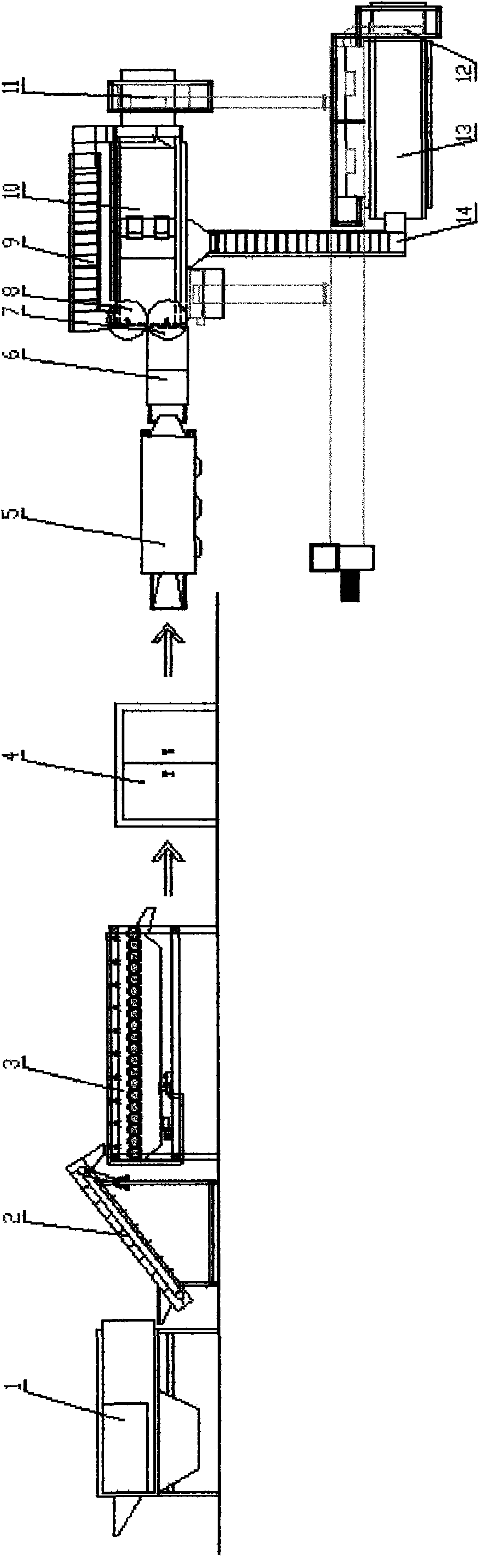

[0029] Legend: 1- Peeling machine; 2- Bucket elevator; 3- Multifunctional high-efficiency cleaning machine; 4- Drying equipment; 5- Classifier; 6-Vertical lifting; 7- Primary shelling machine; 8- Secondary crushing Shelling machine; 9-Scraper lifting Ⅰ; 10- Primary walnut kernel grading machine; 11, 12- Shell kernel separator; 13- Secondary walnut kernel grading machine; 14-Scraper lifting II;

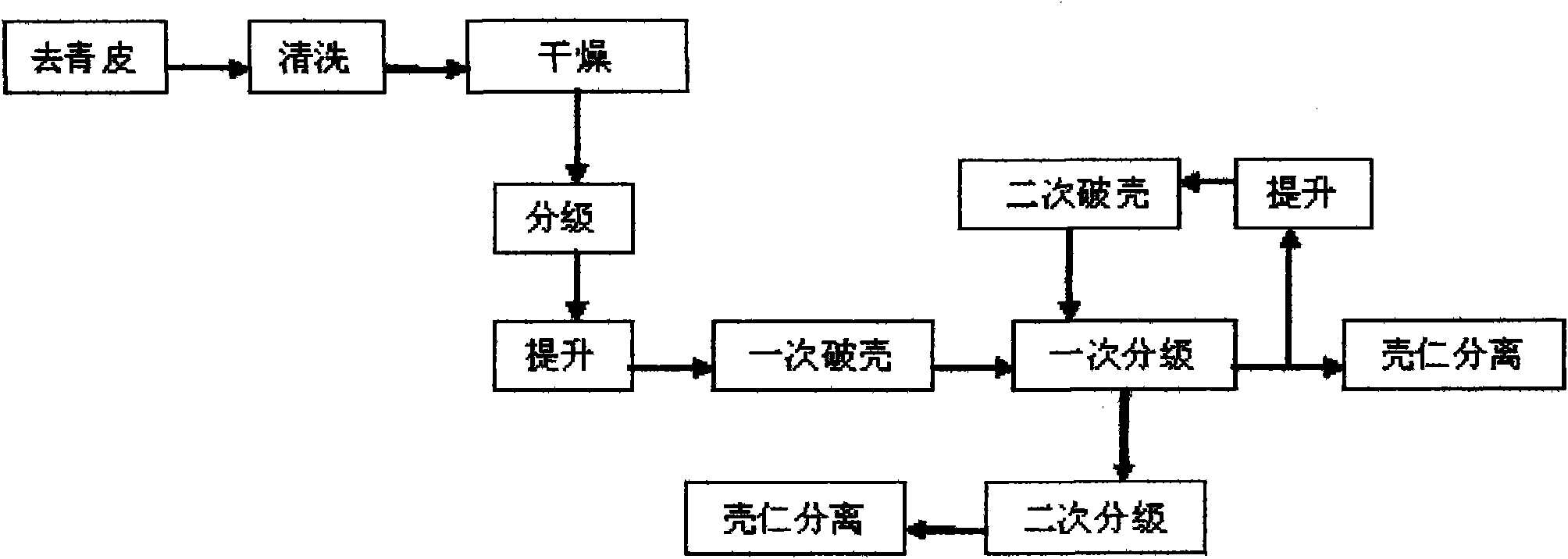

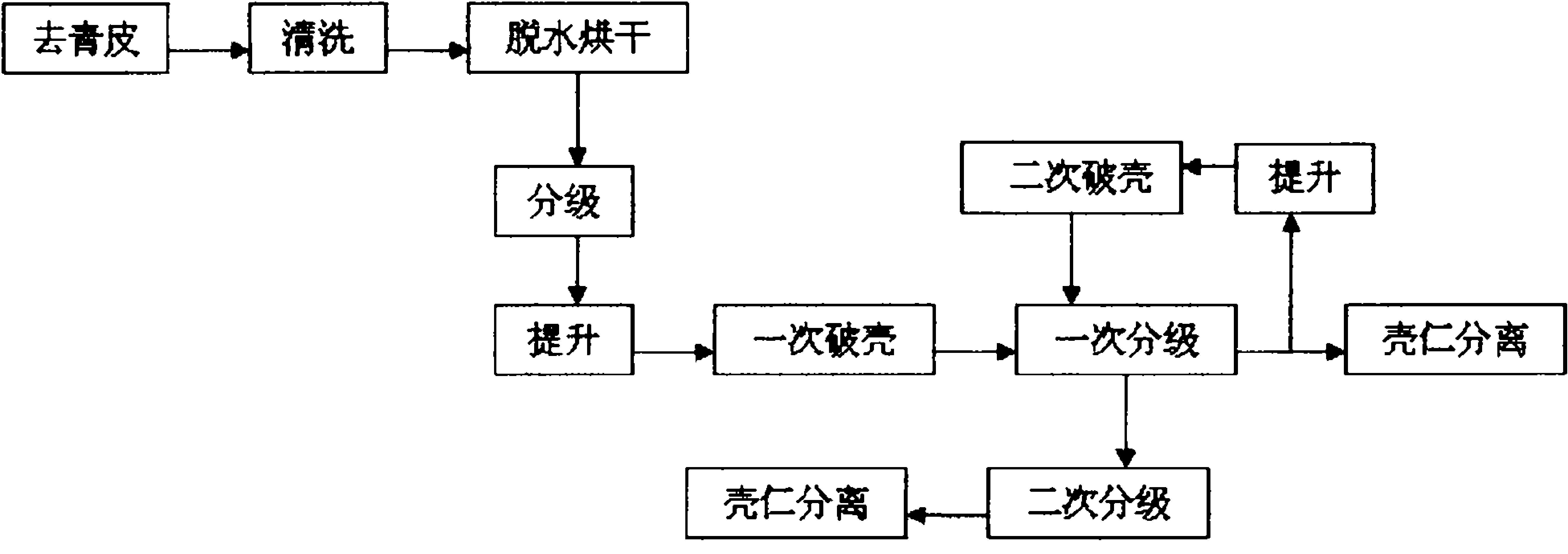

[0030] Such as figure 1 As shown, the production process of the present invention is as follows:

[0031] ①After picking the walnuts with green skin, the green skin on the surface of the walnut is processed by the peeling machine 1, and then sent by the bucket elevator 2 to the multifunctional high-efficiency washing machine 3. The walnut rolls with the rotation of the brush, and there is a high-pressure spray on it. The high-pressure water from the shower tube is rinsed, and the cleaned walnuts enter the drying equipment 4, remove the surface moisture and send to the classifier 5;

[0032] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com