Novel high-efficiency extraction process for astaxanthin in Haematococcus pluvialis

A technology of Haematococcus pluvialis and astaxanthin, which is applied in the direction of organic chemistry and the like, can solve the problems that ultra-high pressure is difficult to achieve industrial application conditions, difficult to separate, and ultrasonic energy consumption is large, and the extraction method is simple and easy to implement and easy to industrialize. The effect of low production and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

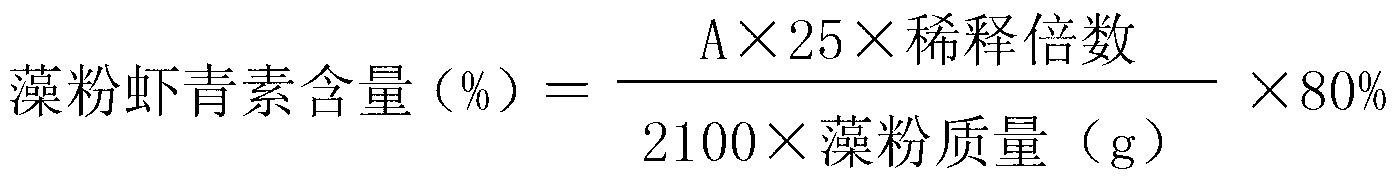

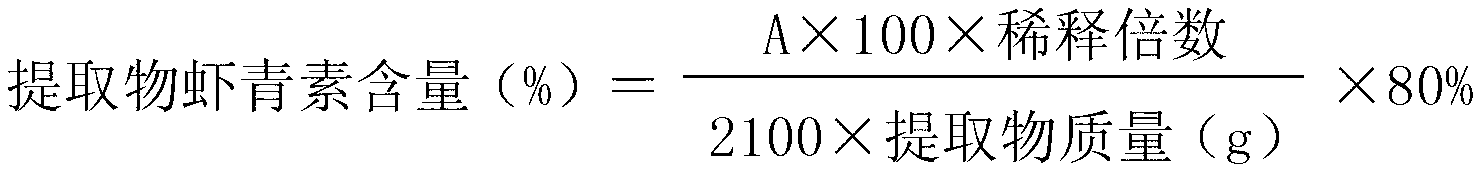

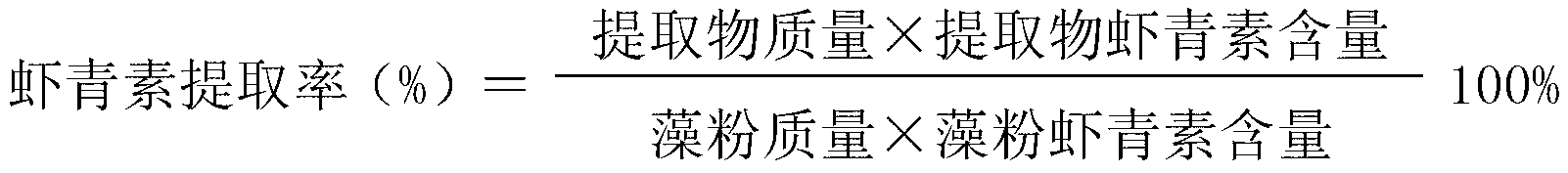

Image

Examples

Embodiment 1

[0039]①Take 20g of dried Haematococcus pluvialis, in which the astaxanthin content is 1.64%, add the dried Haematococcus pluvialls to 100ml of 8% sulfuric acid aqueous solution, put it in a water bath at 80°C and stir for 30min, slowly add 10% NaOH dropwise Stir the aqueous solution continuously, adjust the pH value to neutral, filter, add the filter cake to 100ml 95% ethanol, stir at room temperature for 10min, filter to remove the filtrate, and obtain broken-walled Haematococcus pluvialis;

[0040] ② Stir the broken Haematococcus pluvialis with 100ml and 60ml of ethyl acetate at 50°C for 10 minutes, filter, combine the filtrate, and concentrate in vacuum at 50°C to obtain 5.2g of astaxanthin extract, of which the astaxanthin content is 6.1% , The extraction rate of astaxanthin is 96.7%.

Embodiment 2

[0042] ①Take 20g of dried Haematococcus pluvialis, in which the content of astaxanthin is 1.73%, add the dried Haematococcus pluvialls to 100ml of 10% hydrochloric acid aqueous solution, put it in a 70°C water bath and stir for 20min, slowly add 10% NaOH dropwise Stir the aqueous solution continuously, adjust the pH value to neutral, filter, add the filter cake to 100ml 93% ethanol, stir at room temperature for 10min, filter to remove the filtrate, and obtain broken-walled Haematococcus pluvialis;

[0043] ②The broken Haematococcus pluvialis was extracted with 100ml and 60ml of ethyl acetate:ethanol:acetone 5:3:1 (V:V:V) mixed organic reagent at 50°C for 10min, filtered, and the filtrate was combined. Vacuum concentration at 50°C yielded 5.8 g of astaxanthin extract, wherein the astaxanthin content was 5.7%, and the astaxanthin extraction rate was 95.5%.

Embodiment 3

[0045] ①Take 20kg of dried Haematococcus pluvialis, in which the astaxanthin content is 1.91%, add the dried Haematococcus pluvialls to 110kg of 10% glacial acetic acid aqueous solution, stir at 60°C for 30min, slowly add 10% NaOH aqueous solution dropwise and Stir continuously, control the temperature below 50°C, adjust the pH value to neutral, filter, add the filter cake to 100kg of 92% ethanol, stir at 40°C for 30 minutes, filter and remove the filtrate, and obtain broken-walled Haematococcus pluvialis;

[0046] ② Broken Haematococcus pluvialis was sequentially extracted with 90kg, 50kg, and 50kg of ethyl acetate at 40°C for 30 minutes, filtered, collected the filtrate, and concentrated in vacuum at 60°C to obtain 5.6kg of astaxanthin extract, of which the astaxanthin content was 6.2 %, the extraction rate of astaxanthin is 90.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com