P-type PERC solar energy cell preparation method, cell, assembly and system

A solar cell, N-type technology, applied in the field of solar cells, can solve the problems of scratches on silicon wafers, increase the fragmentation rate, etc., and achieve the effects of increasing the breakage rate, reducing the fragmentation rate, and improving the conversion efficiency of cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

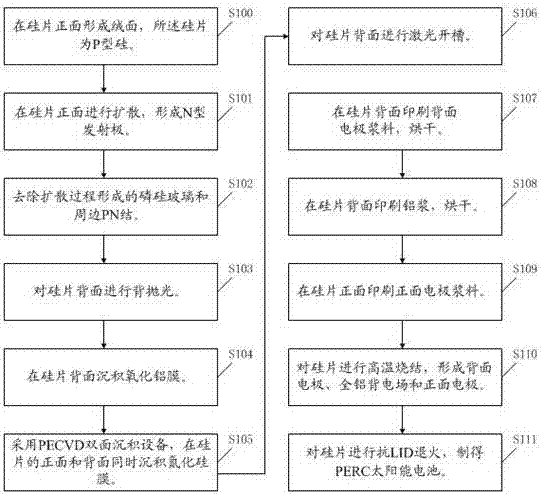

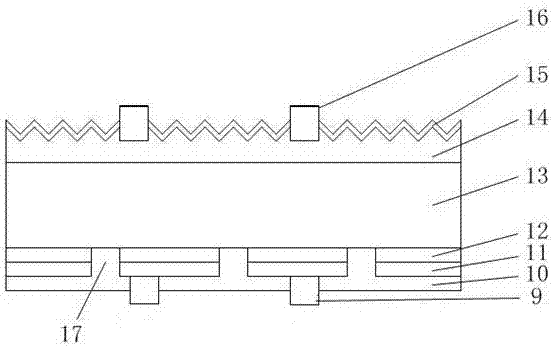

[0039] Such as figure 1 Shown, the present invention provides a kind of preparation method of P-type PERC solar cell, comprises the following steps:

[0040] S100, forming a textured surface on the front side of the silicon wafer, where the silicon wafer is P-type silicon.

[0041] Use wet or dry etching technology to form a textured surface on the surface of the silicon wafer through texturing equipment.

[0042] S101, performing diffusion on the front side of the silicon wafer to form an N-type emitter.

[0043] The diffusion in step S101 of the preparation method of the present invention is to place the silicon wafer in a thermal diffusion furnace for diffusion, and form an N-type emitter above the P-type silicon. During the diffusion, the temperature should be controlled within the range of 800°C-900°C. The target square resistance is 90-150 ohm / □.

[0044] During the diffusion process, a phosphosilicate glass layer will be formed on the front and back of the silicon wa...

Embodiment 1

[0070] (1) Form a textured surface on the front of the silicon wafer by wet texturing, and the silicon wafer is P-type silicon.

[0071] (2) Place the silicon wafer in a thermal diffusion furnace for diffusion, and form an N-type emitter above the P-type silicon. During diffusion, the temperature should be controlled within the range of 840°C, and the target sheet resistance is 90Ω / □.

[0072] (3) Place the diffused silicon wafer in HF and HNO with a volume ratio of 1:5 3 Soak in the mixed solution acid tank for 15s to remove the phosphosilicate glass and surrounding PN junctions.

[0073] (4) Deposit an aluminum oxide film on the back of the silicon wafer using conventional PECVD equipment.

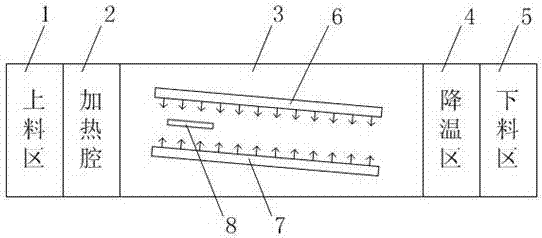

[0074] (5) Use PECVD double-sided deposition equipment to deposit silicon nitride film on the front and back of the silicon wafer at the same time. Among them, the rate of silane gas ejected downward from the vent plate on the process chamber is 1600 sccm, and the rate of ammonia gas is...

Embodiment 2

[0082] (1) Form a textured surface on the front of the silicon wafer by wet texturing, and the silicon wafer is P-type silicon.

[0083] (2) Place the silicon wafer in a thermal diffusion furnace for diffusion, and form an N-type emitter above the P-type silicon. During diffusion, the temperature should be controlled within the range of 830°C, and the target sheet resistance is 100Ω / □.

[0084] (3) Place the diffused silicon wafer in HF and HNO with a volume ratio of 1:5 3 Soak in the mixed solution acid tank for 15s to remove the phosphosilicate glass and surrounding PN junctions.

[0085] (4) Deposit an aluminum oxide film on the back of the silicon wafer using conventional PECVD equipment.

[0086] (5) Use PECVD double-sided deposition equipment to deposit silicon nitride film on the front and back of the silicon wafer at the same time. Among them, the rate of silane gas ejected downward from the vent plate on the process chamber is 1650 sccm, and the rate of ammonia gas i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com