Hob height adjustment methods based on gaskets and positioning blocks

A technology of height adjustment and positioning blocks, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., to prevent mechanism failure and loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

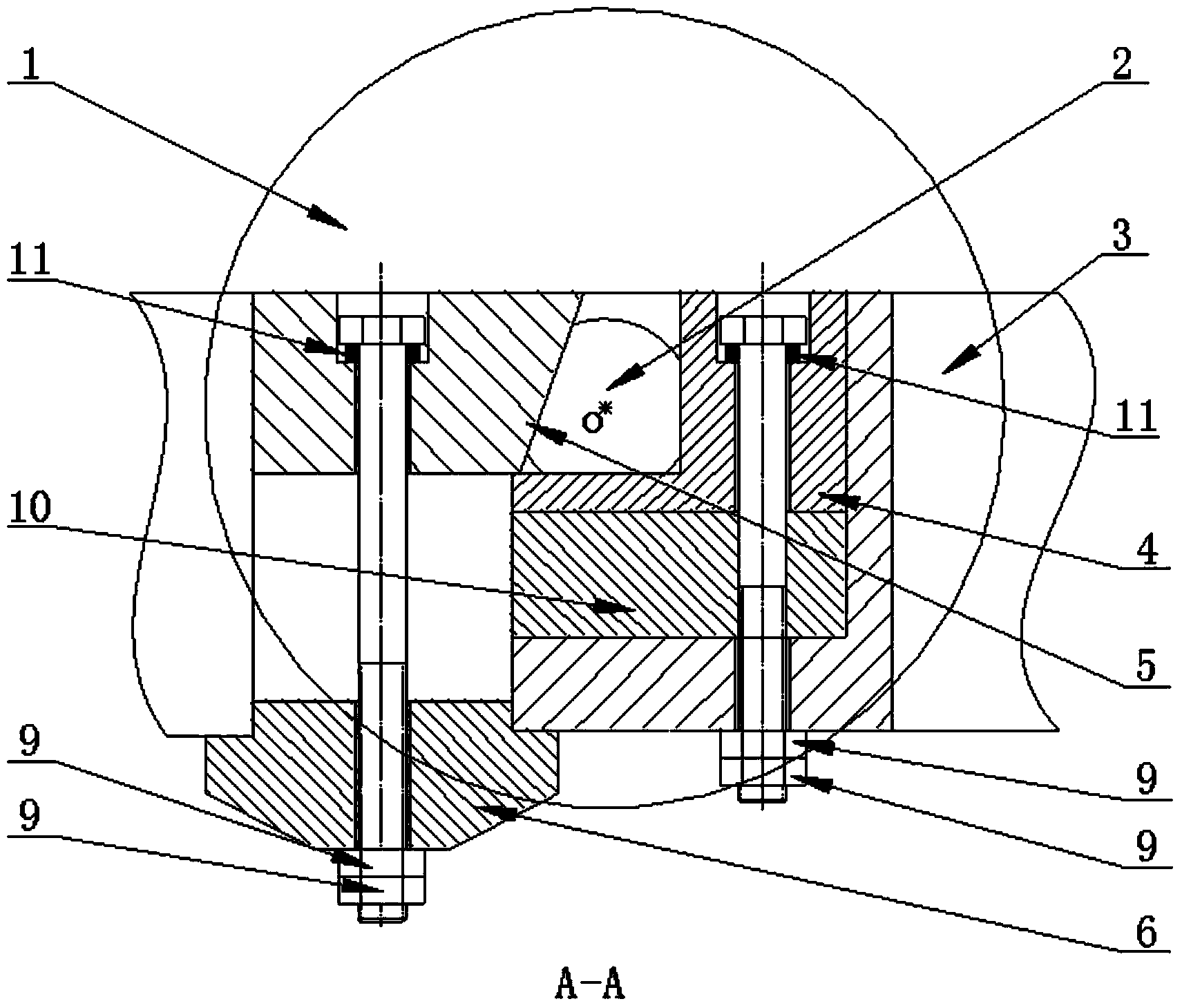

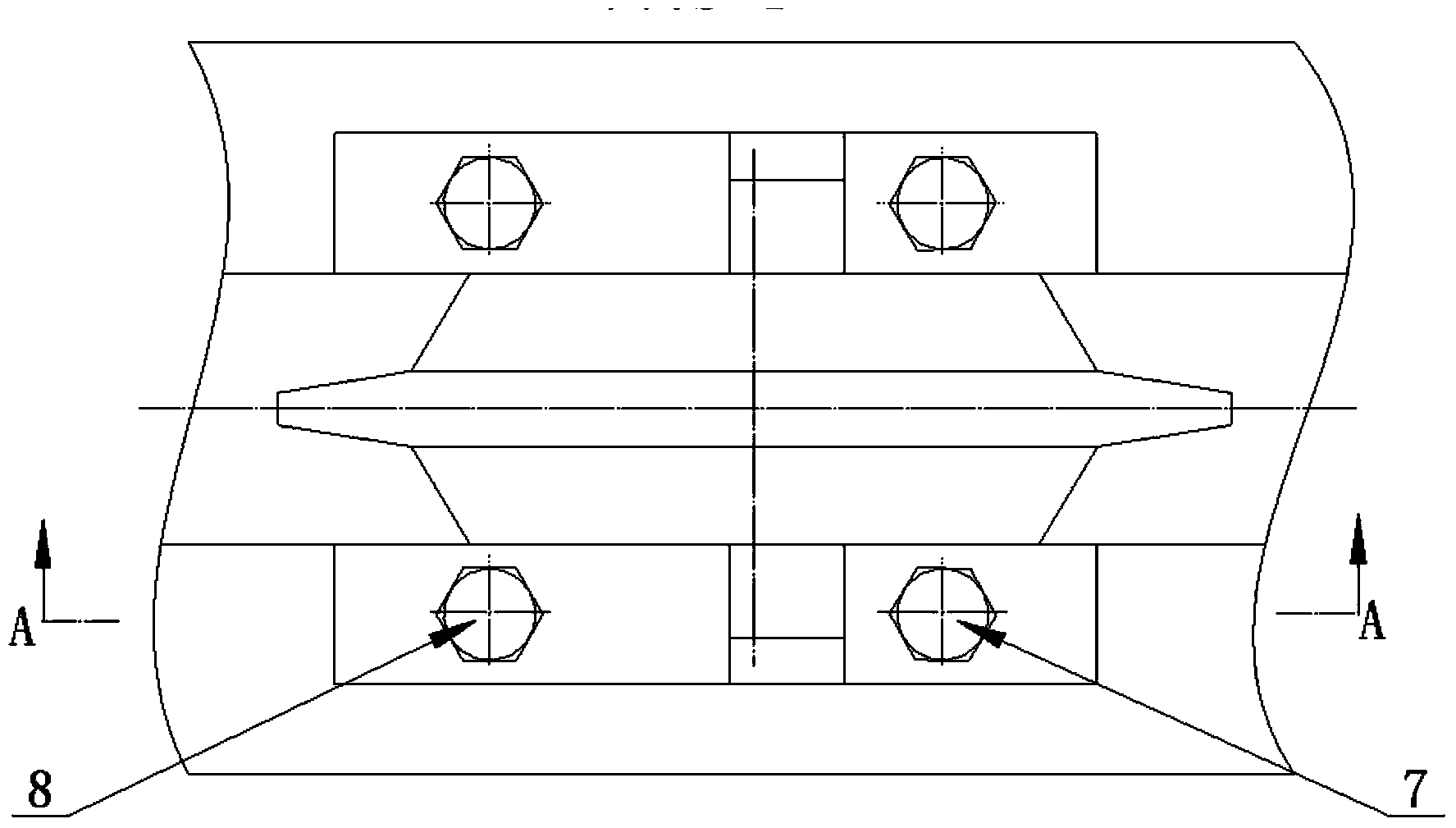

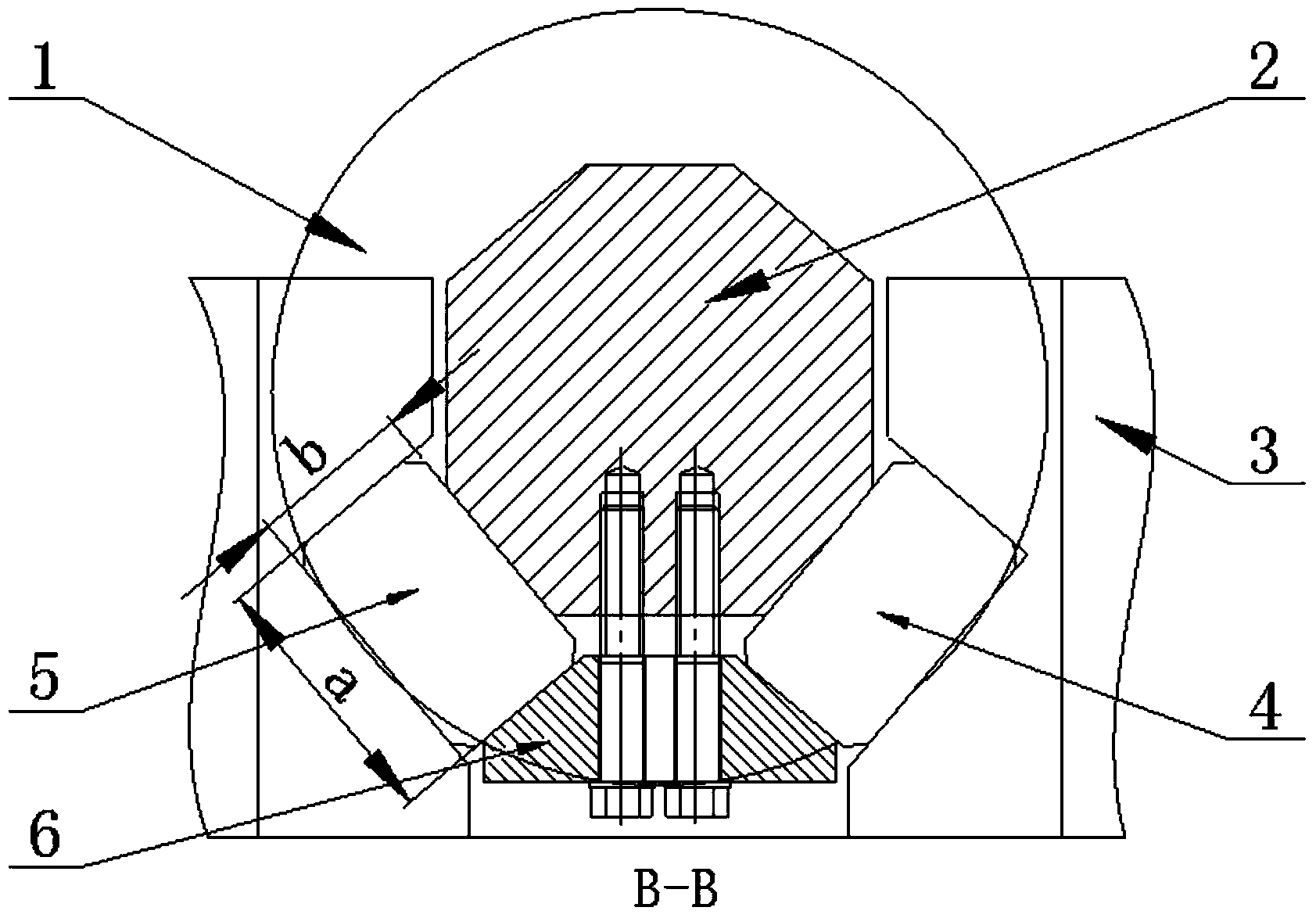

Method used

Image

Examples

Embodiment Construction

[0051] When the construction geology in front is rock with high strength, the depth of cut of the hob is small, and the protruding height of the hob can be appropriately reduced so that the scraper can enter the cutting in advance, which can protect the hob from sinking into the ground and make the knife The increase of the disc torque can also make the scraper cut in advance to give full play to the cutting performance; when the geological condition is soft rock with low strength, the protruding height of the hob can be appropriately increased so that the hob can fully exert its rock-breaking function. The scraper does not enter the cutting before the hob breaks the rock, which prevents the scraper from touching the surface of the rock and soil in advance and hinders the hob from breaking the rock; The block is sized such that the hob height drops below the scraper to protect the hob.

[0052] Aiming at the defect that the height of the current hob cannot be adjusted, the inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com