Disassembly and assembly equipment for bearing box of working roll of aluminum foil mill

A technology for aluminum foil rolling mills and work rolls, applied in metal processing equipment, metal rolling stands, metal rolling mill stands, etc., can solve problems such as abnormal damage and low efficiency of disassembly and assembly, so as to save time and avoid work roll bearings Effects of damage and shortened installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

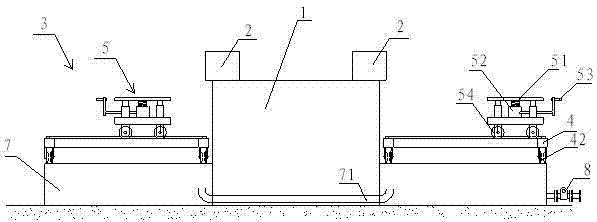

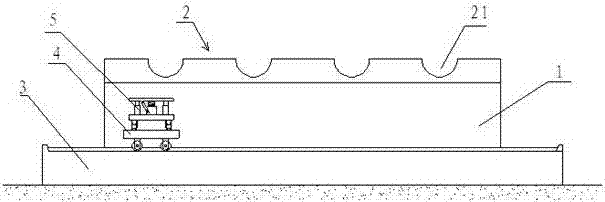

[0034] refer to figure 1 As shown, an aluminum foil rolling mill working roll bearing box dismantling equipment includes a roll bed 1; U-shaped frames 2 are arranged on both sides of the top surface of the roll bed 1 for placing work rolls 9; workbenches 3 on both sides of the roll bed 1 , used to carry the operating device; the operating device includes a horizontally moving cart 4 arranged on the top surface of the workbench 3, and a mobile trolley 5 capable of lifting and longitudinally moving is arranged on the laterally moving cart 4.

[0035] Among them, such as figure 1 and figure 2 As shown, the moving trolley 5 is provided with a lifting platform 51, a turbine, a worm structure 52, a rocking rod 53 and wheels 54, and the lifting platform 51 is realized by controlling the rocking rod 53 to control the lifting of the turbine and the worm mechanism 52.

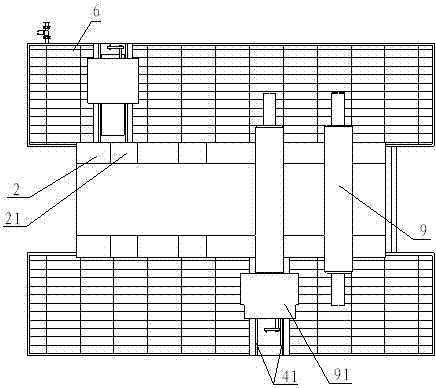

[0036] Such as image 3 As shown, the upper surface of the laterally moving cart 4 is provided with a track 41, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com