Novel elastic coupler

An elastic coupling, a new type of technology, applied in elastic couplings, couplings, mechanical equipment, etc., can solve the problems of high assembly process requirements and inconvenient operation, avoid abnormal damage, improve installation efficiency, improve The effect of smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

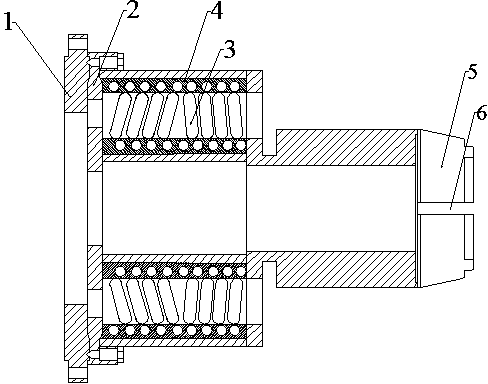

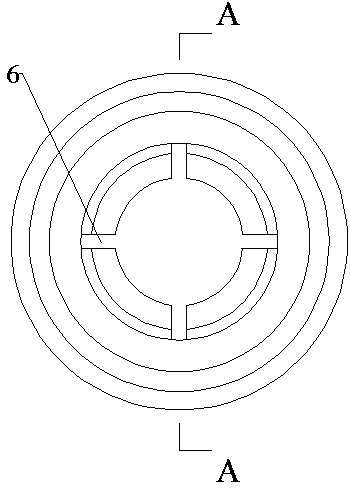

[0021] Such as figure 1 , figure 2 As shown, a new type of elastic coupling includes an active hub body and a driven hub body, and the active hub body is uniformly arranged with a spiral elastic body 3 and a fixed connection mechanism 4 in the circumferential direction; the spiral elastic body 3 is multi-strand stainless steel The twisted wire is symmetrically wound with an equal-pitch helical structure; the fixed connection mechanism 4 is a single stainless steel wire wound on the helical elastic body 3, and the fixed connection mechanism 4 enables sufficient space between the master and slave hubs of the coupling. The ring-shaped free deformation space makes the coupling have different rigidity in the axial, radial and torsional directions, realizes the elastic connection between the driving shaft and the driven shaft, and automatically compensates the shafting under installation and operating conditions The position offset; the helical elastic body 3 produces bending hys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com