Fuel injector supporting ring capable of effectively reducing work noise of gasoline direct injection engine

A gasoline direct injection and fuel injector technology, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve problems such as the inability to effectively damp the vibration transmission of the fuel injector and the increase in the noise level of the whole machine, so as to improve the noise of the whole vehicle level, reduction of operating noise, effect of reduction of operating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

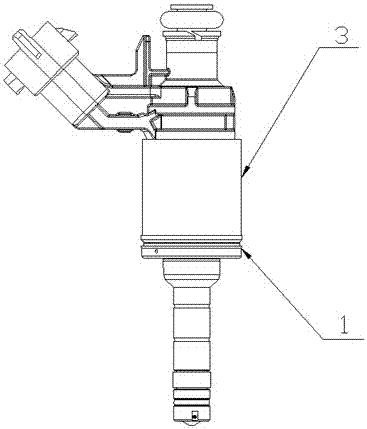

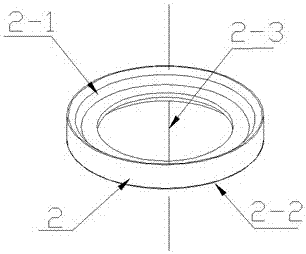

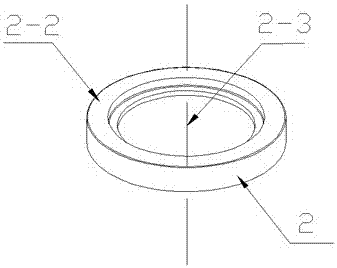

[0022] see Figure 4 , Figure 5 , Figure 6 , an injector support ring structure that can effectively reduce the working noise of a gasoline direct injection engine includes an upper retaining ring 1-1, a lower retaining ring 1-3 and an elastic connecting part 1-2, and the upper retaining ring 1-1 is used for connecting with the injector The oiler body 3 is connected, and the lower retaining ring 1-3 is used for connecting with the engine block. The elastic connecting part is a hollow cylindrical structure, and the upper retaining ring 1-1, the lower retaining ring 1-3 and the middle elastic connecting part 1-2 are welded together.

[0023] see Figure 7 , the upper retaining ring 1-1 of the fuel injector support ring is a thin-walled stepped through-hole structure, which is stamped and formed, and is composed of an upper stepped part 1-8, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com