Block valve capable of being opened and closed reversely

A valve, reverse technology, applied in the field of reverse opening and closing cut-off valves, can solve the problems of poor sealing, valves cannot be closed tightly, large closing force, etc., achieve long service life, easy production and manufacturing, and reduce operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

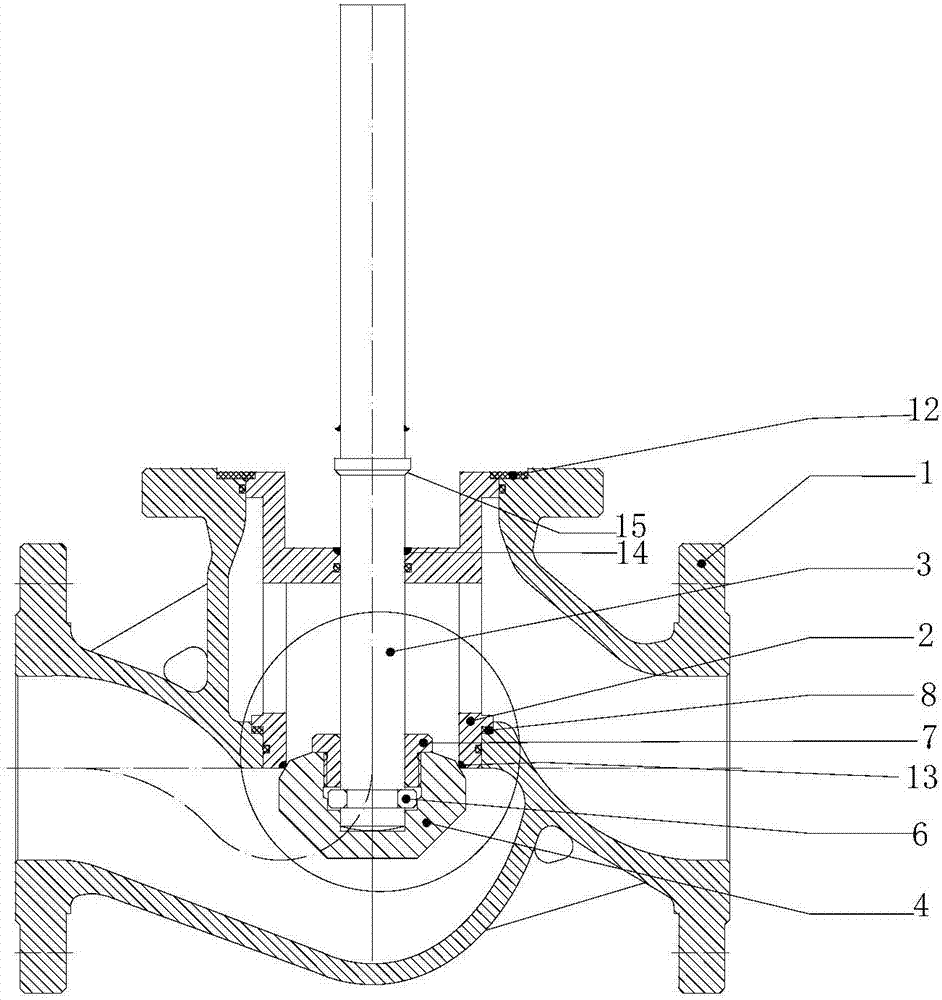

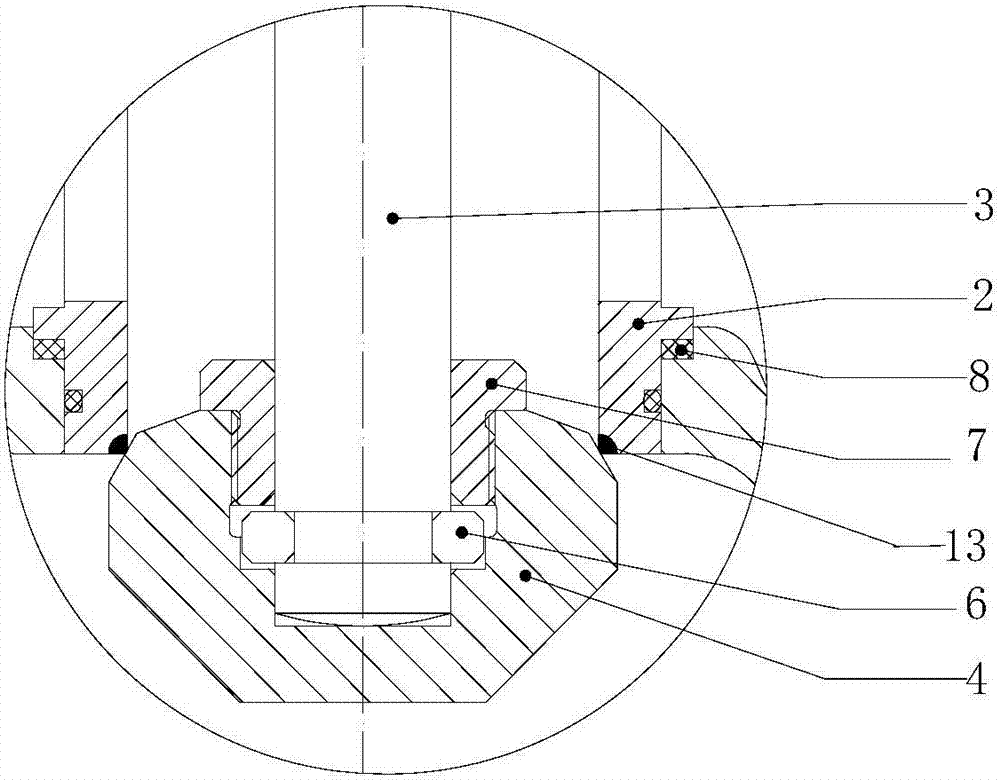

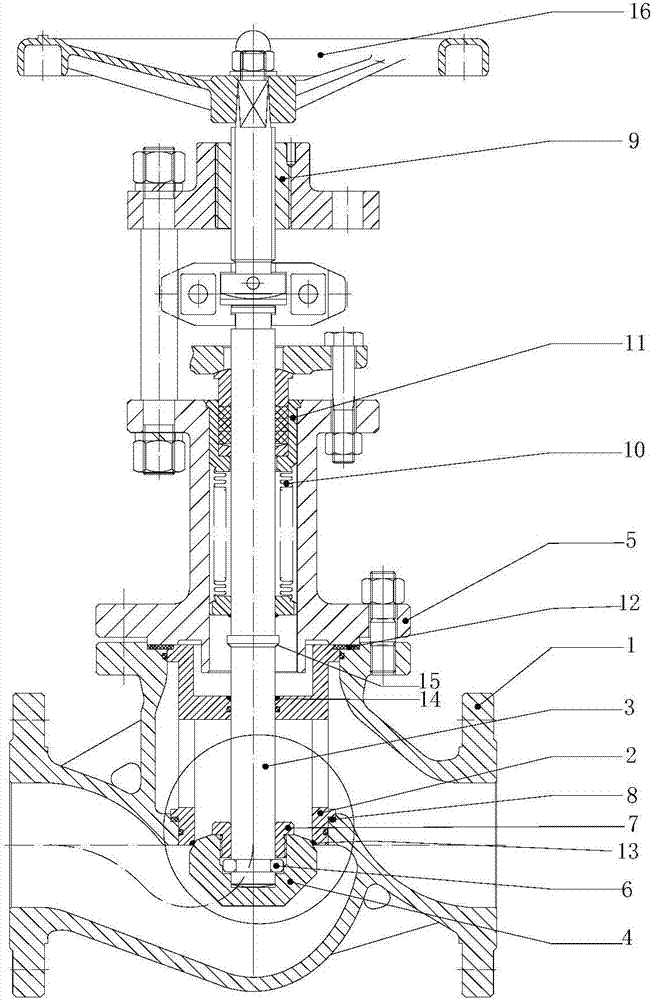

[0050] Reverse opening and closing cut-off valves, such as figure 1As shown, the reverse opening and closing cut-off valve includes a valve body 1, a valve seat 2, a valve stem 3, a valve disc 4, a split ring 6 and a valve disc cover 7; the valve seat 2 and the through hole in the middle of the valve body 1, the valve The rod 3 is arranged in the through hole of the valve body 1 and the valve seat 2 and can move up and down; the maximum width of the valve disc 4 is larger than the diameter of the internal through hole of the valve seat 2 and is located below the valve seat 2, and the middle part of the valve disc 4 is provided with a blind hole , used to connect with the valve stem 3; the split ring 6 is arranged in the ring groove of the valve stem 3, between the valve stem 3 and the valve disc 4, and the outer diameter of the split ring 6 is larger than the diameter of the valve stem 3; the valve The inside of the flap cover 7 is a through hole with a diameter smaller than t...

Embodiment 2

[0061] Reverse opening and closing cut-off valve, including valve body 1, valve seat 2, valve stem 3, valve disc 4 and valve disc cover 7, the inside of the valve disc cover 7 is a through hole, different from the embodiment 1, there is no split circle The ring 6, the disc cover 7, the disc 4 and the valve stem 3 are directly and detachably connected, such as through threaded connection, so as to connect the valve stem 3 and the valve disc 4 together, so that the valve stem 3 is up and down The movement can drive the valve clack 4 to move up and down.

Embodiment 3

[0063] The reverse opening and closing cut-off valve is different from Embodiment 2 in that there is no disc cover 7, but the valve disc and the valve stem are fixedly connected together by welding, so that the valve stem 3 and the valve disc 4 are connected together. Together, the up and down movement of the valve rod 3 can drive the up and down movement of the valve disc 4 .

[0064] In this case, there is no gap between the blind hole in the valve disc 4 and the valve stem 3, or there is no gap between the contact upper part of the valve disc 4 and the valve stem 3, so as to ensure that the particles in the medium will not be deposited In the depression of the valve clack, the lower part of the valve stem 3 is not welded with the valve clack 4, and the lower end surface of the valve stem 3 is not necessarily welded to the valve clack 4 either. Or, it is also possible that the lower end surface of the valve stem 3 is welded to the valve disc 4, and the upper part or all of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com