Predictive maintenance method and system

A predictive and reliable technology used in test/monitor control systems, general control systems, control/regulation systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following examples are exemplary. Although the specification may refer to "an", "an" or "some" embodiments in several places, this does not necessarily mean that each such reference refers to the same embodiment, or that the feature applies to only a single embodiment . Individual features of different embodiments may also be combined to provide other embodiments.

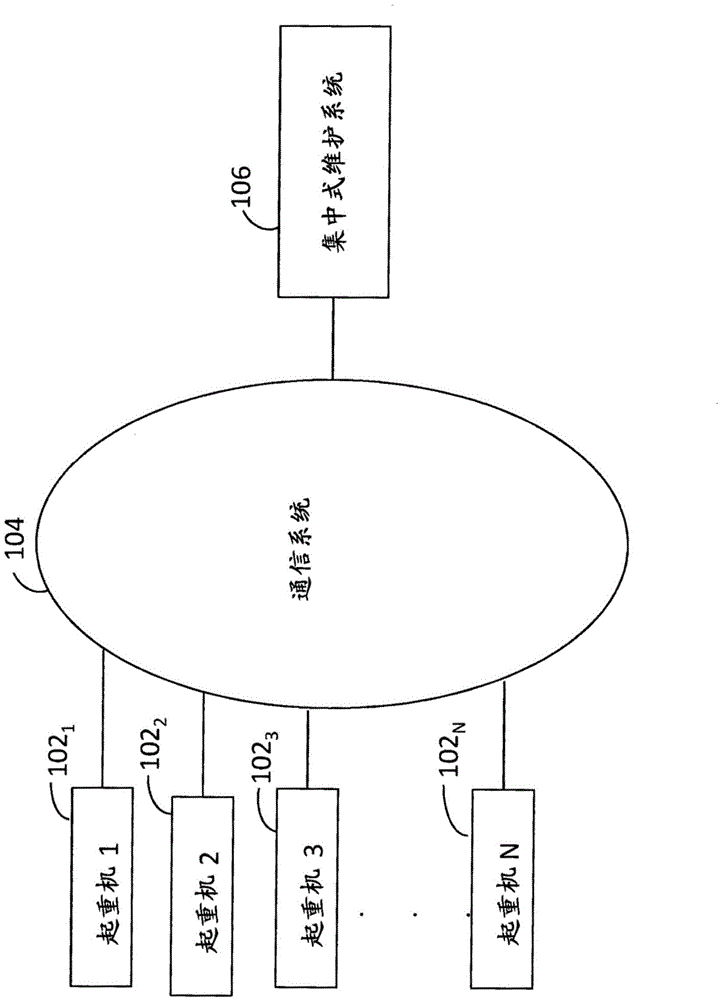

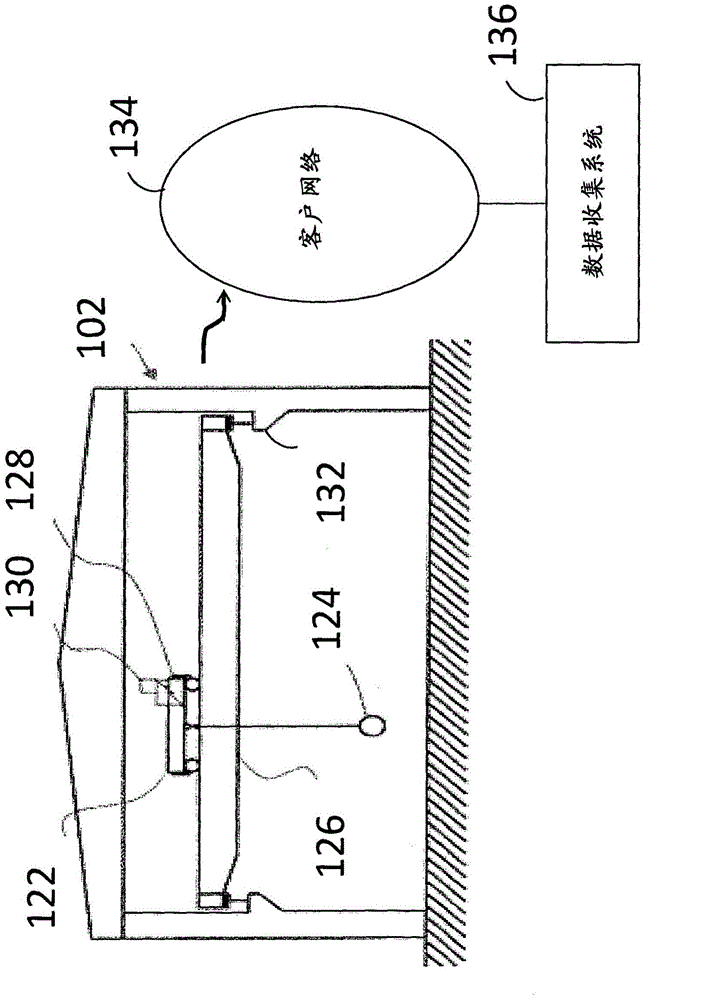

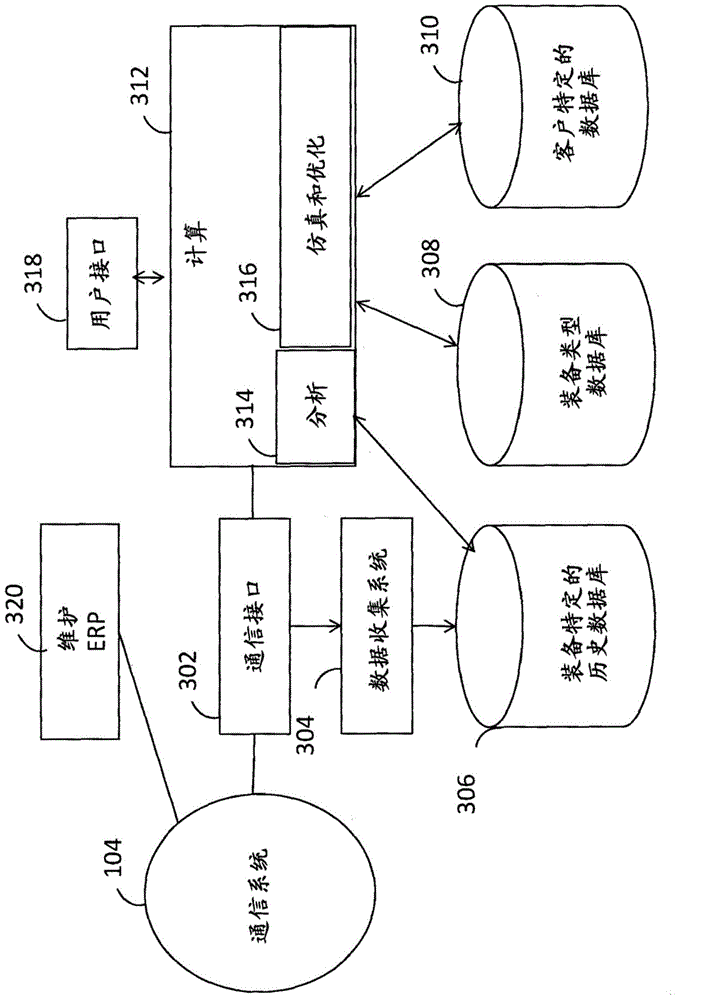

[0038] An aspect of the present invention is to provide an automatically optimized equipment specific predictive maintenance scheme aimed at having reduced life cycle costs and increased reliability and safety. A predictive maintenance scheme may be a self-learning scheme, where optimal learning is based on information provided by multiple (eg, entire fleets) of equipment such that the provided information is used to optimize maintenance of individual equipment. This makes it possible to more accurately predict the life cycle of equipment at the point of sale or already at the beginning of the life cyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com