Feedforward type electric resistance welding quality monitoring system and method

A quality monitoring and resistance welding technology, applied in resistance welding equipment, welding monitoring devices, welding power sources, etc., it can solve the problem that the current cannot stably control the quality of resistance welding, avoid the generation and overflow of welding defects, and achieve high accuracy. , easy to monitor and manage the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

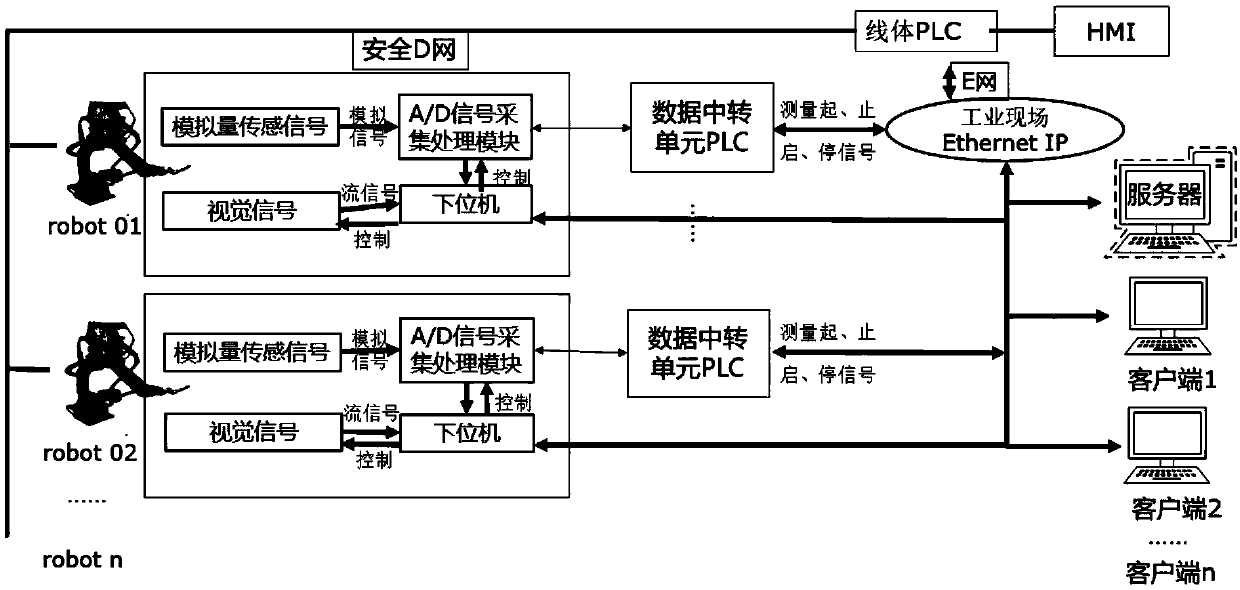

[0080] A feed-forward resistance welding quality monitoring system, such as figure 1 As shown, it includes a server and a sensor group, the sensor group is arranged on a fixed column, the fixed column is located on one side within the range of movement of the welding torch, and is connected to the server through Ethernet.

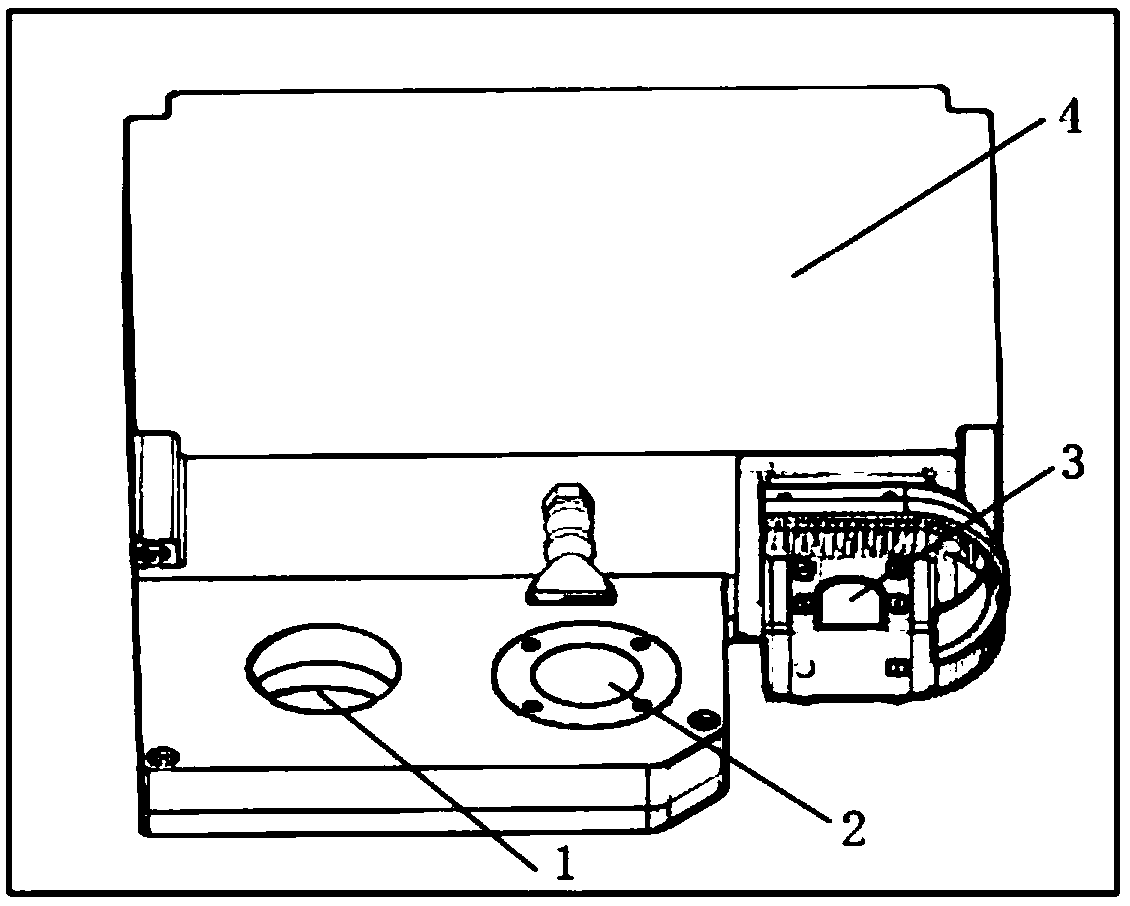

[0081] The sensor set, such as figure 2 As shown, it includes an analog sensing signal detection window, an A / D signal acquisition and processing circuit, a visual signal detection window and a lower computer; the analog sensing signal detection window is connected to the A / D signal acquisition and processing circuit, The A / D signal acquisition and processing circuit and the visual signal detection window are connected to the lower computer; the lower computer is connected to the server signal.

[0082] The analog sensor signal detection window and the visual signal detection window are exposed outside the packaging box and arranged side by side; the A / D ...

Embodiment 2

[0089] A feed-forward resistance welding quality monitoring method, comprising the following steps:

[0090] (1) Control the resistance welding torch to be detected to periodically enter the area of the feedforward resistance welding quality monitoring system provided in Embodiment 1, and be respectively in the sensing signal detection window and the visual signal detection window; specifically:

[0091] Write a test program by PLC to start the system. The program periodically controls the welding robot, which is equipped with a welding torch. The line body PLC program will control the mechanical arm on the welding robot to move the welding torch to the area of the feedforward resistance welding quality monitoring system provided in Embodiment 1, which are respectively in the sensor signal detection window and the visual signal detection window.

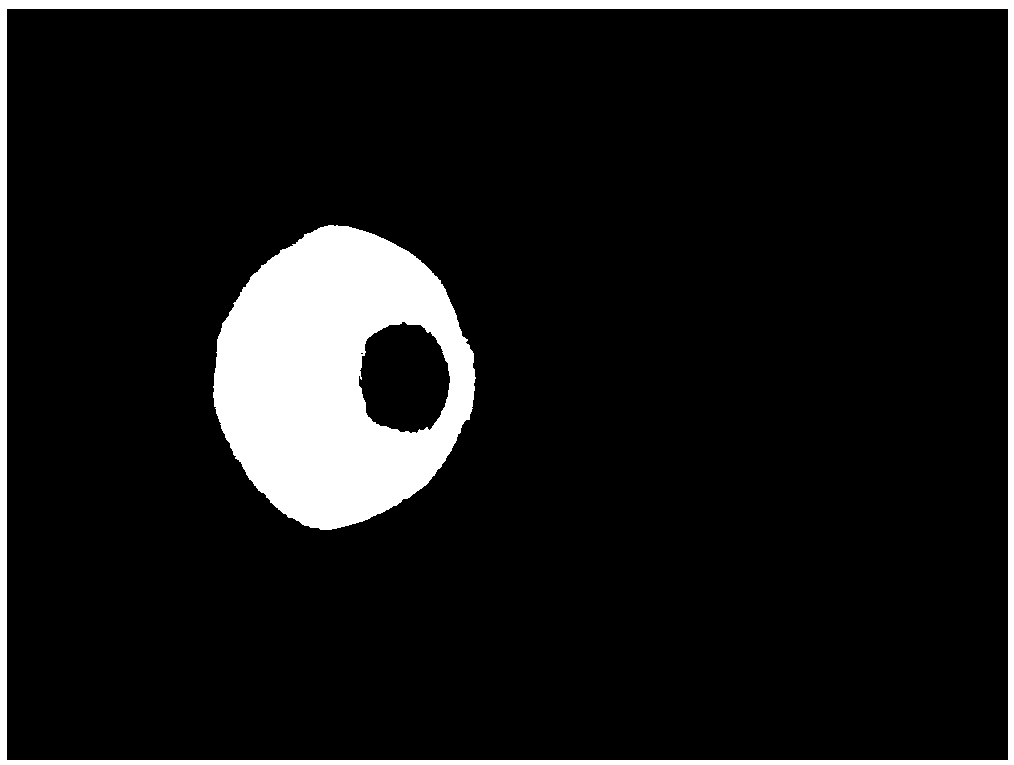

[0092] (2) The lower computer controls the A / D signal acquisition and processing circuit to collect the analog signal detected b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com