Methyl heptol desulfurizing process

A technology of methylheptanol and sulfide, applied in the field of methylheptanol removal of sulfide, can solve the problems of product quality not up to standard, high production cost, low yield, etc., to avoid catalyst poisoning, ensure normal operation, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

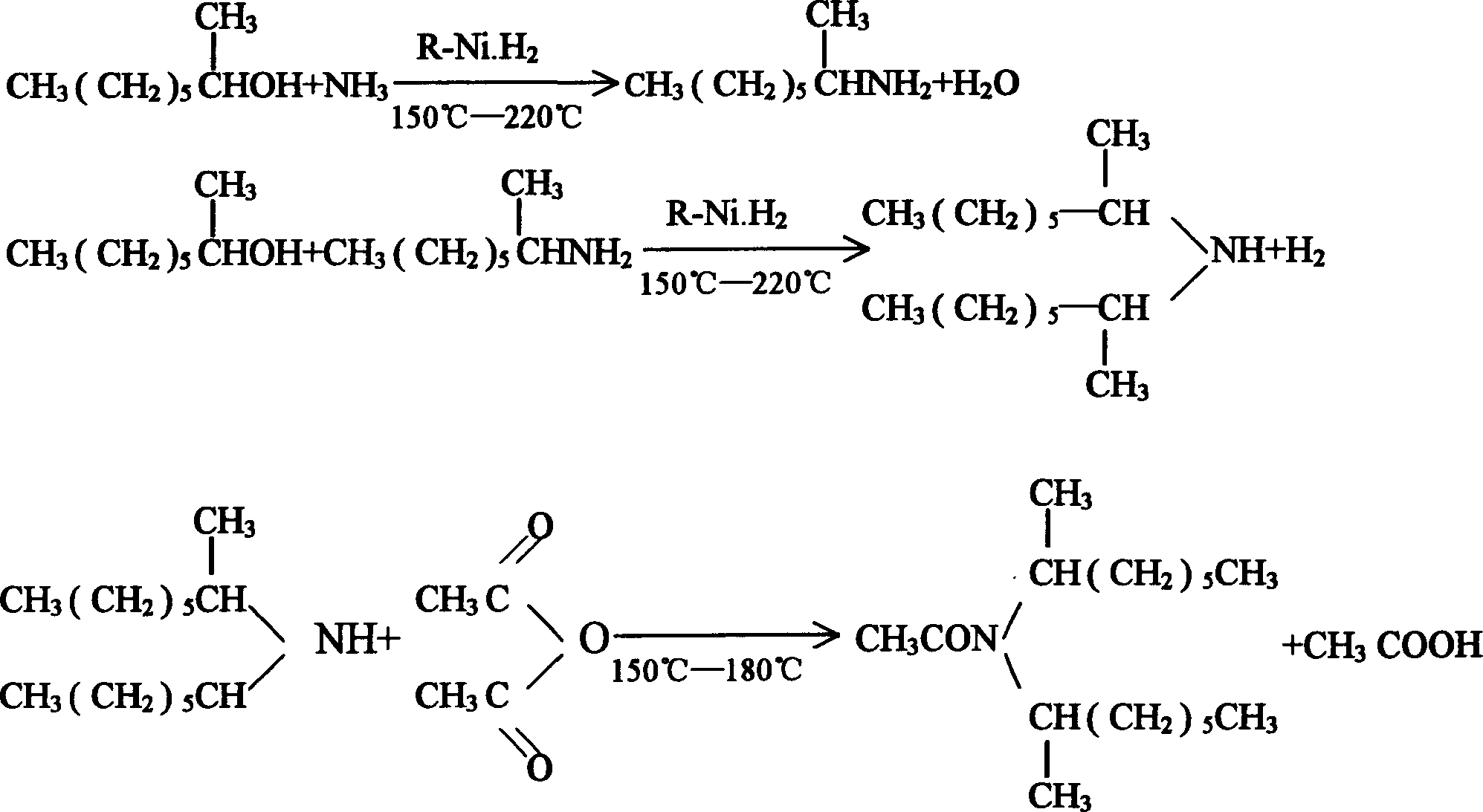

Method used

Image

Examples

Embodiment Construction

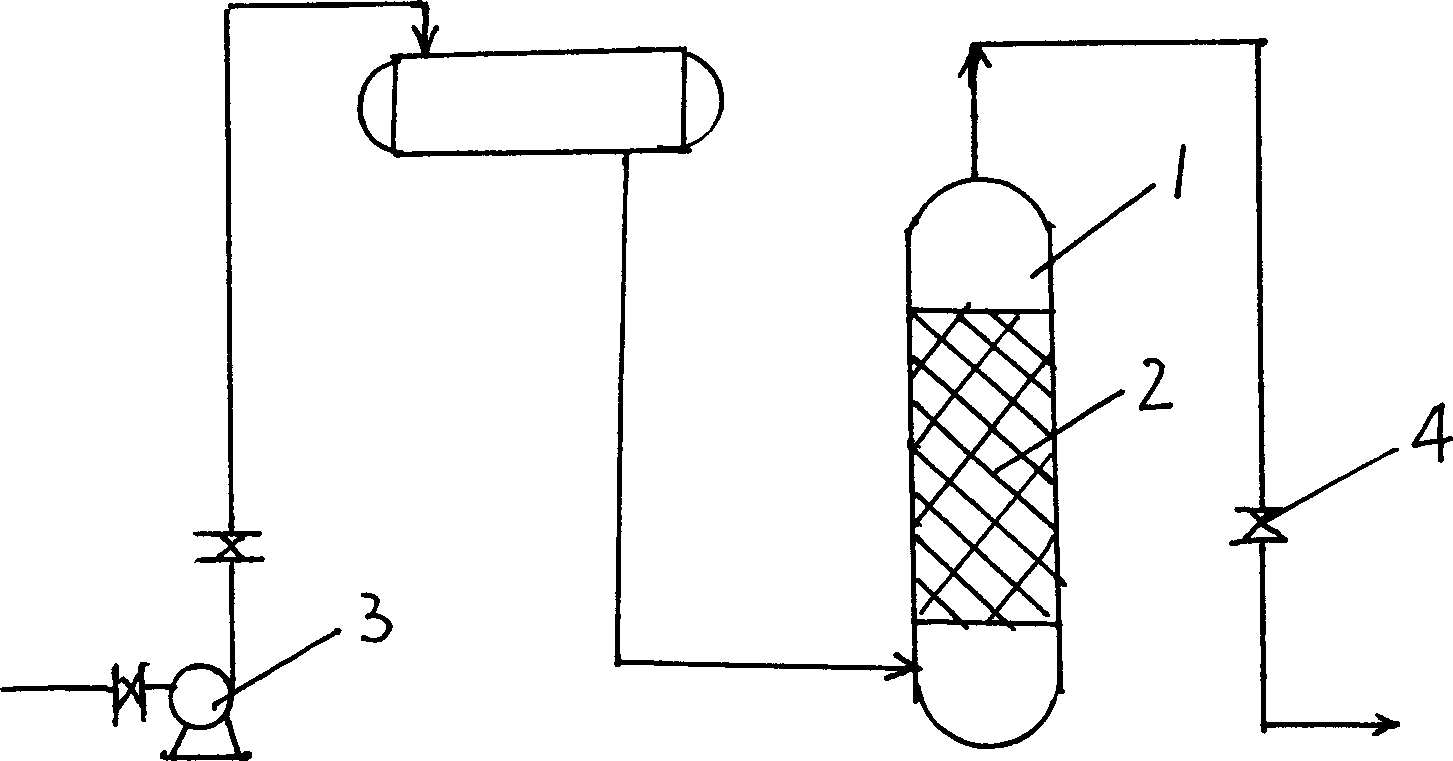

[0011] Such as figure 1 As shown, the main equipment for the removal of sulfide from methylheptanol is the self-designed sulfide removal tower 1, which is cylindrical, with round platforms at both ends, 5-9 meters high, and a built-in 3.5-6 meters high SN-3 Type activated carbon desulfurizer layer 2 (produced by Shanghai Research Institute of Chemical Industry), the methylheptanol after distilling and removing water is sent to the high-level storage tank by pump 3, and the methylheptanol in the high-level storage tank flows into the tower from the bottom of the tower and passes through the desulfurizer layer. Afterwards, it flows into the ammonolysis section methyl-heptanol storage tank through valve 4 from the tower top overflow pipe for subsequent use, and the outlet flow is controlled so that the methyl-heptanol containing sulfide is less than 2PPm.

[0012] Comparison table of ammonolysis reaction of methylheptanol to remove sulfide and unremoved sulfide (average number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com