Anti-blocking system based on computer analog simulation

A simulation and computer technology, applied in design optimization/simulation, conveyor objects, containers, etc., can solve problems such as single and non-adjustable blanking direction, affect the operating environment of the workshop, and materials are too late for blanking, etc., to achieve simplified structure, durability Good abrasiveness and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

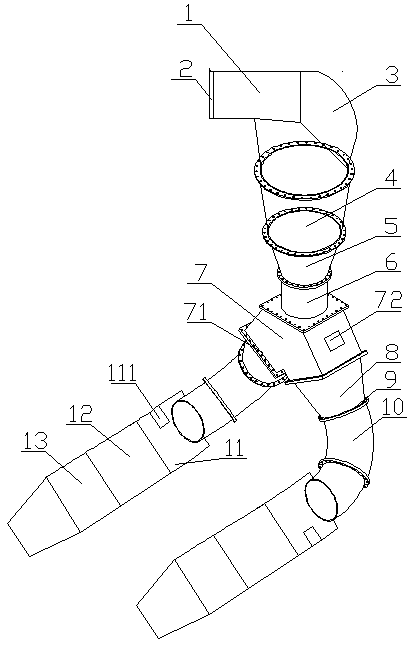

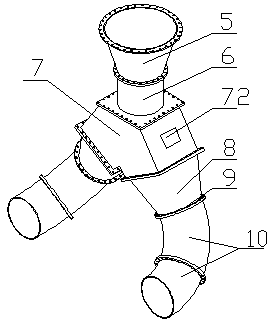

[0023] like Figure 1-2 As shown, an anti-blocking material system based on computer simulation of the present invention includes a drum guard 1, which is provided with a feed port 2 and is connected to a head guard 3 at the same time; The cover 1 adopts a square structure, and the feed port 2 is located at its front end; the head shield 3 is a circular arc structure, and the bottom is connected to the transition hopper 4; specifically, the head shield adopts a streamlined arc design, which is relatively The material entering the transfer system is preliminarily shaped, and the radian of the streamline is designed to be 1 / 6π~1 / 2π, which corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com