Tapping and smoke exhausting system of rotary submerged arc furnace

A smoke exhaust system and submerged arc furnace technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve the problems of disorderly discharge of smoke, increase of total smoke volume, increase of fan power loss, etc., and achieve precise and directional smoke exhaust , prevent splashing and overflowing, and solve dust environmental protection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

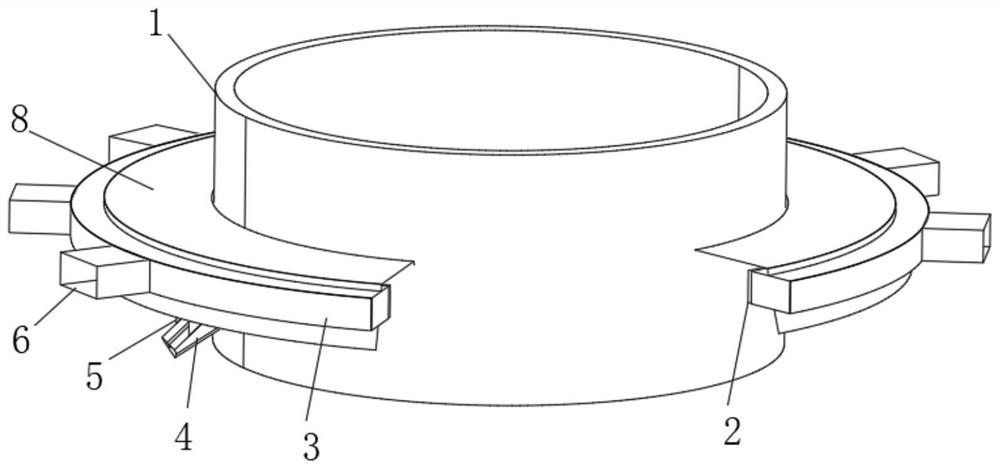

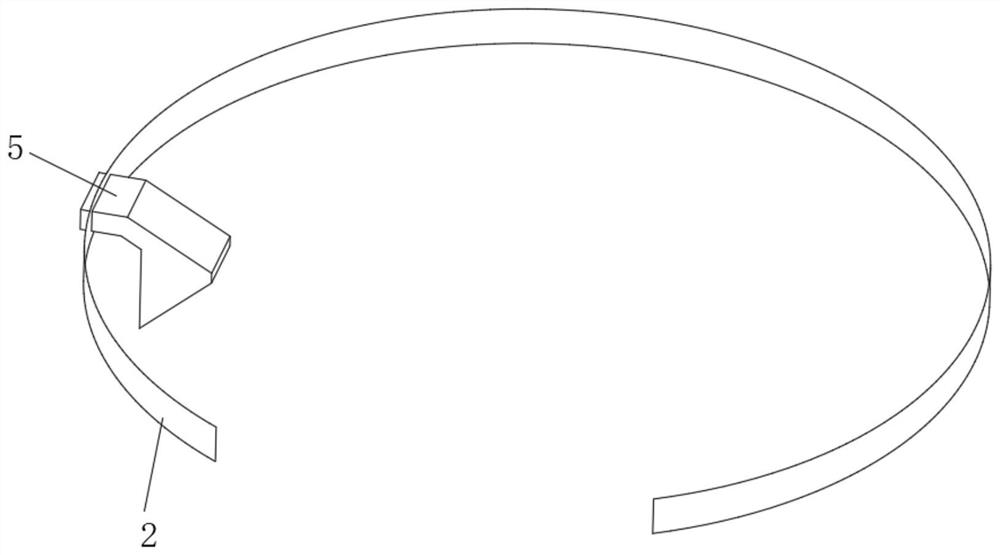

[0037] combine Figure 1-2 As shown, the embodiment of the present invention provides a rotary type submerged arc furnace tapping fume exhaust system, including a chute fume collecting hood 5, an annular baffle 2, an annular flue 3 and several fume exhaust hoods 6; the chute The fume collecting hood 5 includes a fume collecting port and a fume outlet, the fume collecting port of the chute fume collecting hood 5 is fixedly connected above the tap hole 4 of the submerged arc furnace, and the fume outlet of the chute fume collecting hood 5 is fixedly connected to the annular baffle plate 2; the annular baffle 2 surrounds the periphery of the submerged arc furnace 1, and rotates with the submerged arc furnace 1 together with the chute fume collecting hood 5;

[0038]The annular flue 3 is fixed on the periphery of the annular baffle 2, and a number of smoke exhaust hoods 6 are fixedly arranged on the outer side wall of the annular flue 3 at even intervals, and the smoke exhaust hoo...

Embodiment 2

[0040] The embodiments of the present invention make the following improvements on the basis of the above-mentioned embodiments:

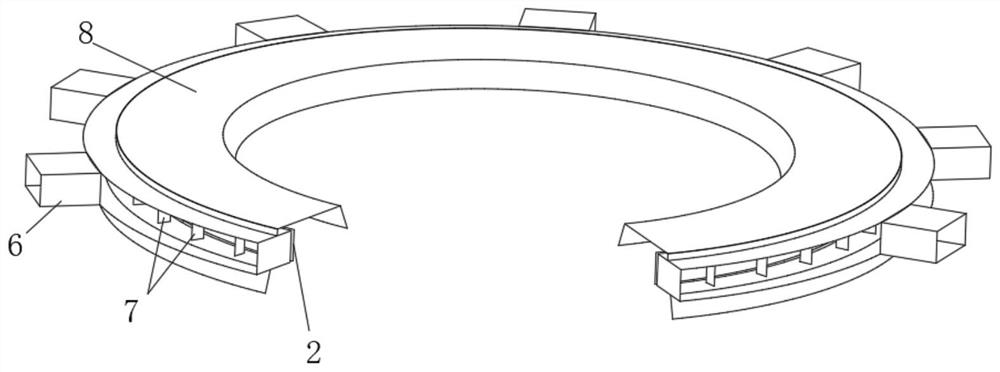

[0041] A gap of 100mm is left at the butt joint of the annular baffle 2 and the annular flue 3; an annular outer hood 8 is fixed above the annular duct 3, and the annular outer hood 8 can collect the overflowing molten iron ladle. The flue gas enters the annular flue through the gap between the annular flue 3 and the annular baffle 2 .

[0042] In the embodiment of the present invention, a gap of 80-150mm is left at the butt joint of the annular baffle 2 and the annular flue 3, so that the annular baffle 2 and the chute smoke collecting hood 5 rotate together with the submerged arc furnace 1, The annular baffle 2 can be prevented from rotating interference with the fixed annular flue 3 through the set gap; at the same time, an annular outer hood 8 with an n-shaped cross-section is fixed above the annular flue 3, so The annular outer fume hood 8 ca...

Embodiment 3

[0044] The embodiments of the present invention make the following improvements on the basis of the above-mentioned embodiments:

[0045] like image 3 As shown, several grilles 7 are arranged at intervals inside the annular flue, and two adjacent grilles 7 gather the flue gas collected by the chute fume collecting hood 5 in a small space, and discharge the smoke from the corresponding exhaust gas. The hood 6 is discharged; the fume exhaust hood 6 is a rectangular parallelepiped, and the width of the fume exhaust port of the fume exhaust hood 6 is smaller than the distance between the corresponding two adjacent grilles 7, which is convenient for the collection and discharge of the flue gas.

[0046] In the embodiment of the present invention, a valve for controlling the closing or opening of the smoke exhaust branch pipe is provided on the smoke exhaust branch pipe communicating with the smoke exhaust hood 6; , the valve on the smoke exhaust branch pipe of the corresponding s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com