Drawing method of gas turbine generator rotor in overhauling operation

A technology for generator rotors and gas turbines, which is used in the manufacture of motor generators, electromechanical devices, electrical components, etc., can solve problems such as low efficiency, affecting production and operation, and time-consuming and laborious extraction of generator rotors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

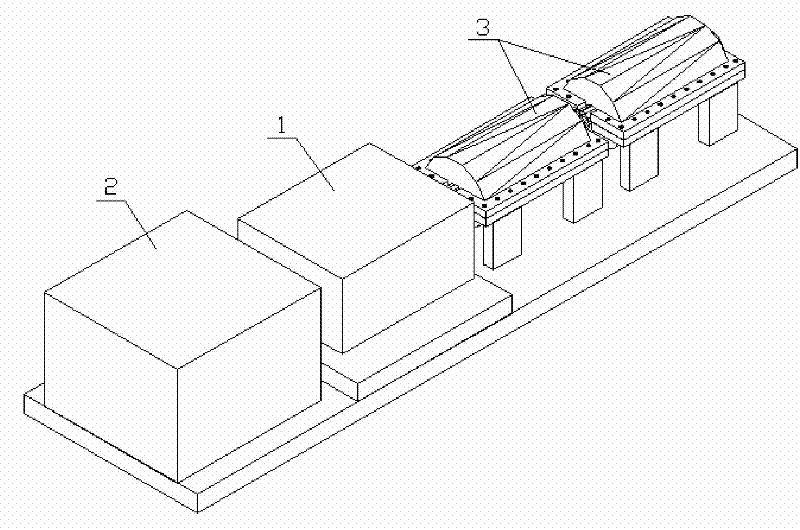

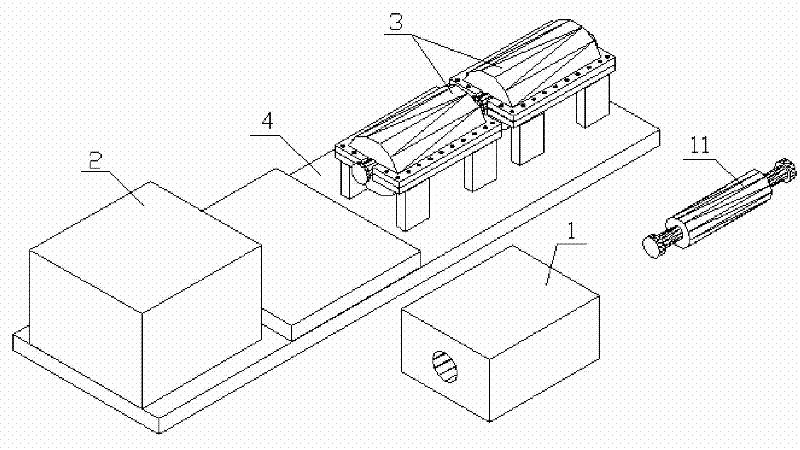

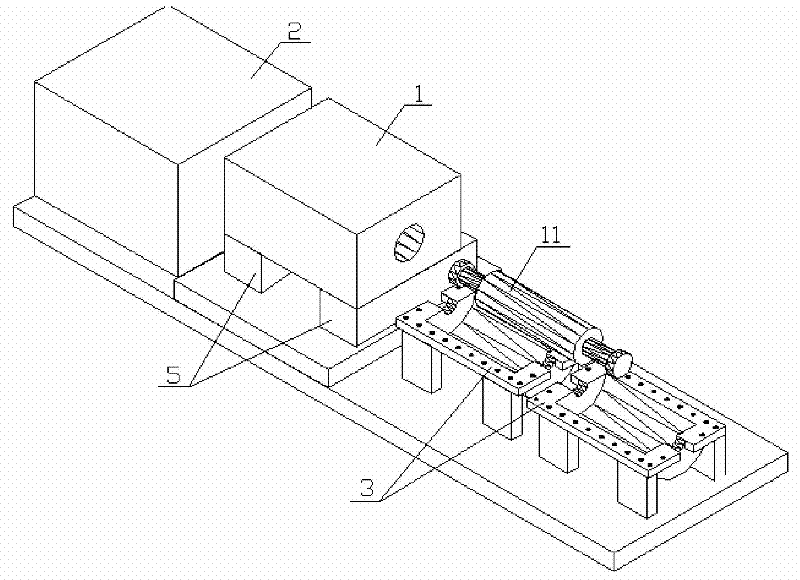

[0017] As shown in 3, the method for extracting the rotor of a gas turbine generator in the maintenance operation of the present invention includes a generator 1 and a gas compressor 3 connected to the generator 1, and the method includes the following steps:

[0018] Step 1. When the gas compressor 3 is disassembled for overhaul, all the components of the gas compressor 3 are disassembled and hoisted out, and the pipelines and electrical wiring connected to the generator 1 are all disconnected at the connection ends without dismantling ;

[0019] Step 2: Install several hydraulic jacks at the bottom of the generator 1 and lift the generator 1 as a whole until the outer diameter of the rotor 11 of the generator 1 exceeds the center height of the gas compressor 3;

[0020] Step 3: Pad a cushion block 5 bearing the weight of the generator 1 at the bottom of the lifted generator 1, so that the generator 1 sits on the cushion block 5 stably;

[0021] Step 4: Extract the rotor 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com