Broken bag locating-detecting device and method for distributed optical fiber bag type dust collector

A technology for positioning detection devices and dust collectors, which is applied in the direction of measuring devices, optical testing flaws/defects, instruments, etc. It can solve the problems of sticky dust on sensing probes, false alarms in leak detection, manual inspections, etc., and achieve resistance to high voltage and high The impact of current, the rate of false alarm and false alarm is reduced, and the effect of ensuring production operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

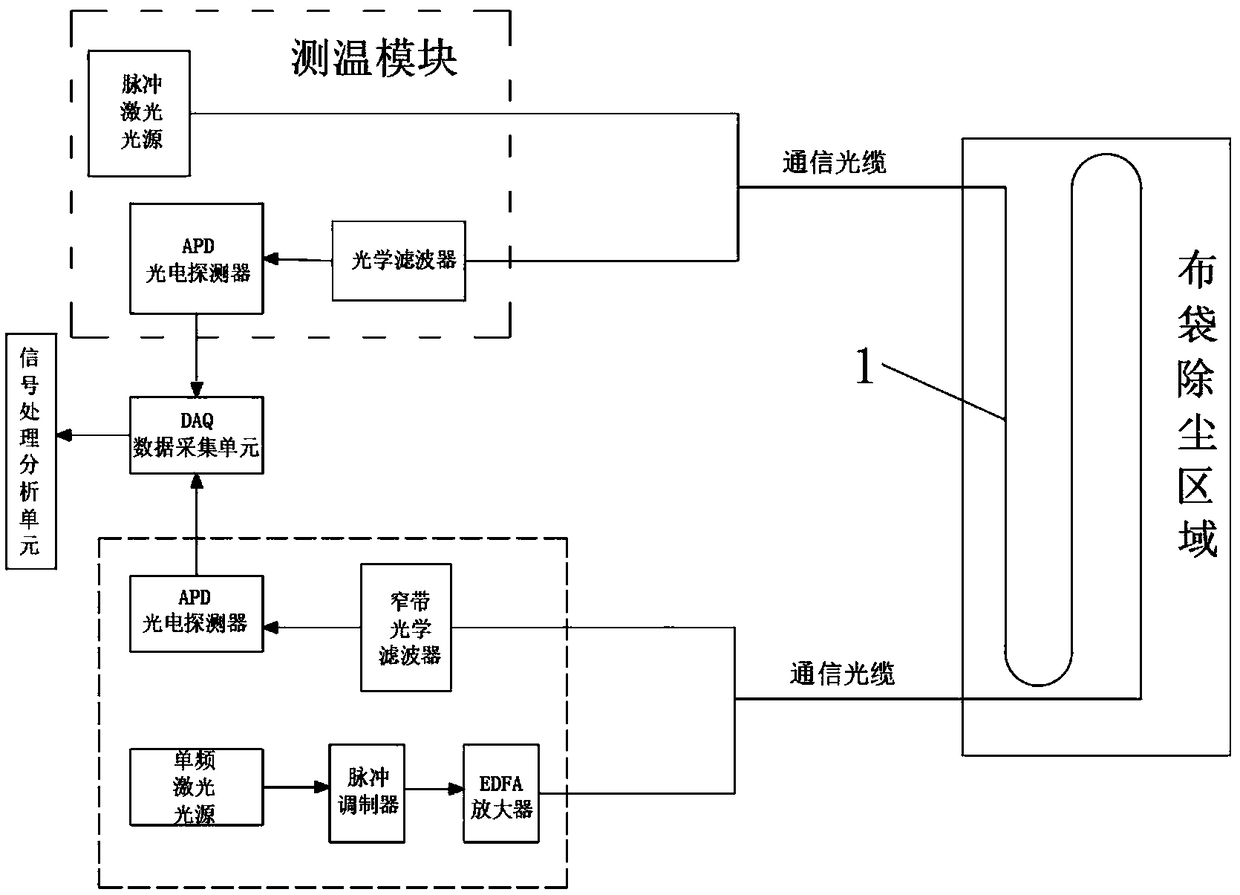

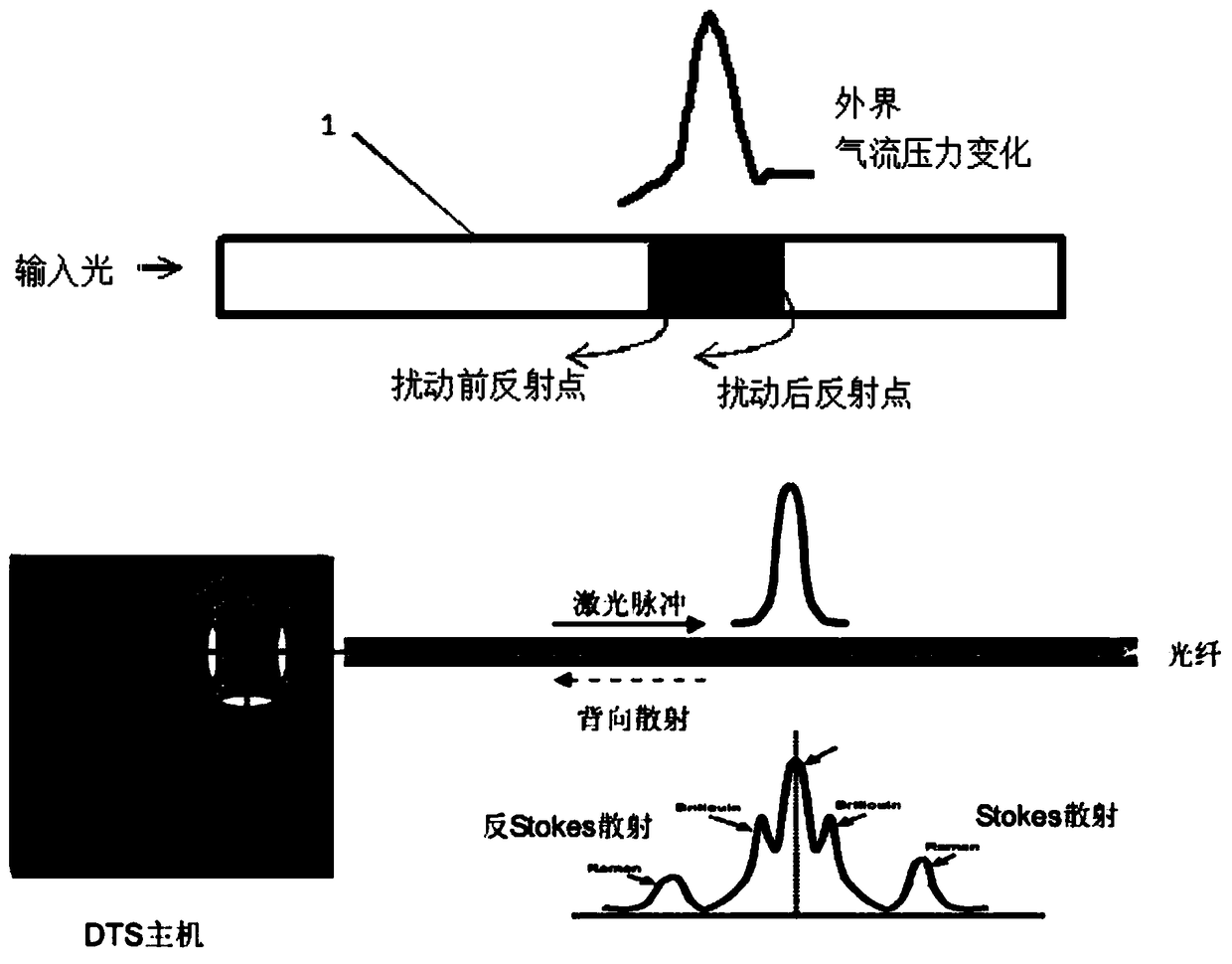

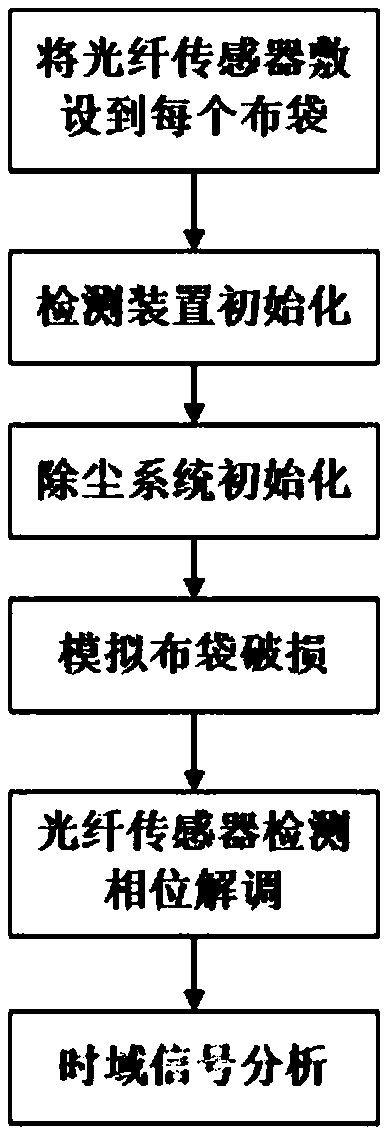

[0042] like figure 1 As shown, a distributed optical fiber bag filter leakage detection device and its method, including: a single-frequency laser light source to provide coherent light energy for the optical fiber sensor; pulse modulator, used to output the single-frequency laser light source Light is converted into pulsed light with a certain pulse width and repetition frequency; EDFA amplifiers are used to amplify pulsed light with a certain pulse width and repetition frequency; narrow-band optical filters allow only narrow-band and narrow-linewidth lasers to pass through in optical fiber communication systems ; APD photodetector, the photodetector circuit is used to amplify, process and shape the weak voltage or current signal output by the photoelectric conversion device; the optical fiber sensor is an ordinary communication optical cable, which is used to detect the airflow caused by the damage of the bag change; the DAQ data acquisition unit performs analog-to-digital ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com