Automatic temperature control carbon fiber heating deicing device of medium-low speed maglev transportation power supply rail

A technology of power supply rail and carbon fiber, which is applied in the direction of ohmic resistance heating parts, rail, track cleaning, etc. Ice phenomenon, effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

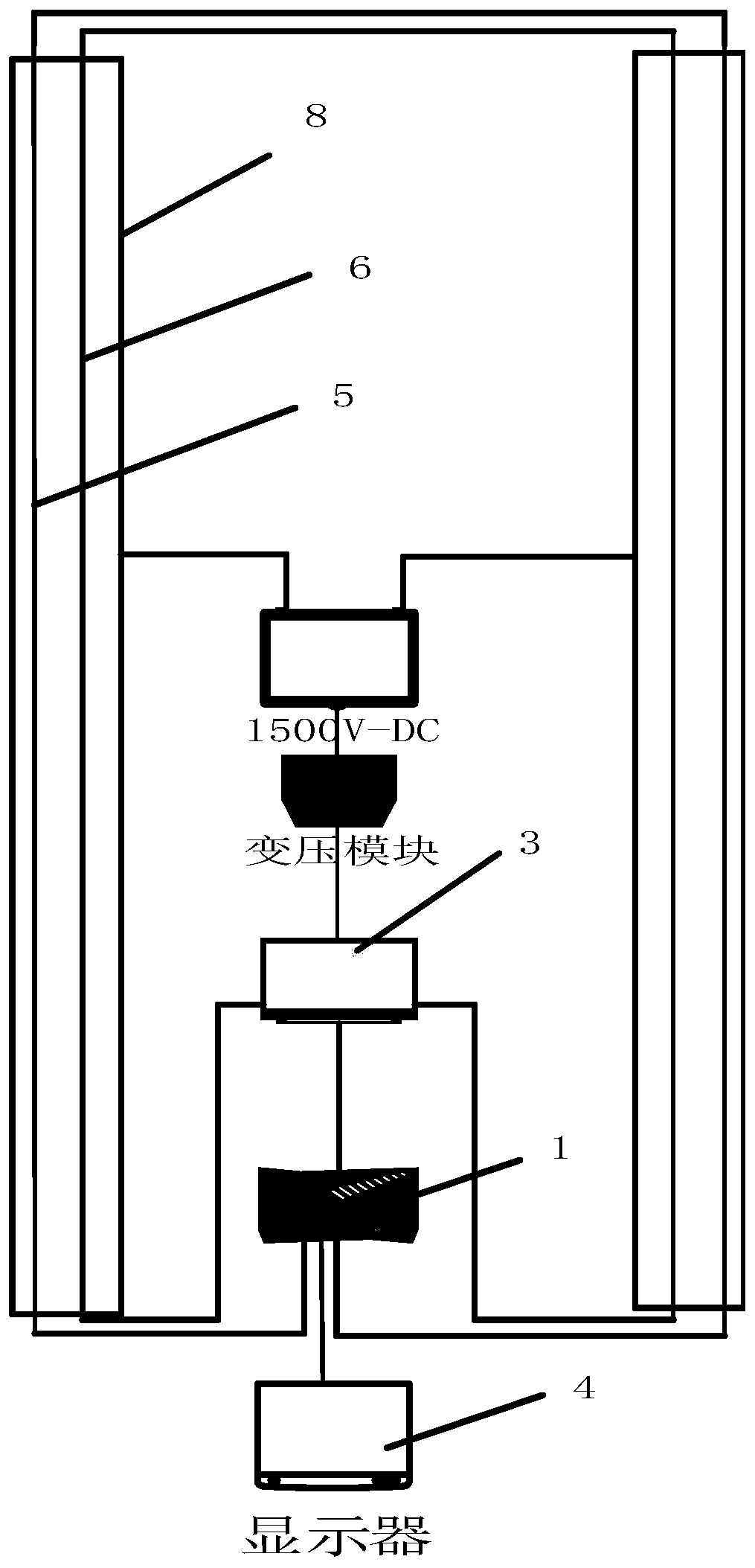

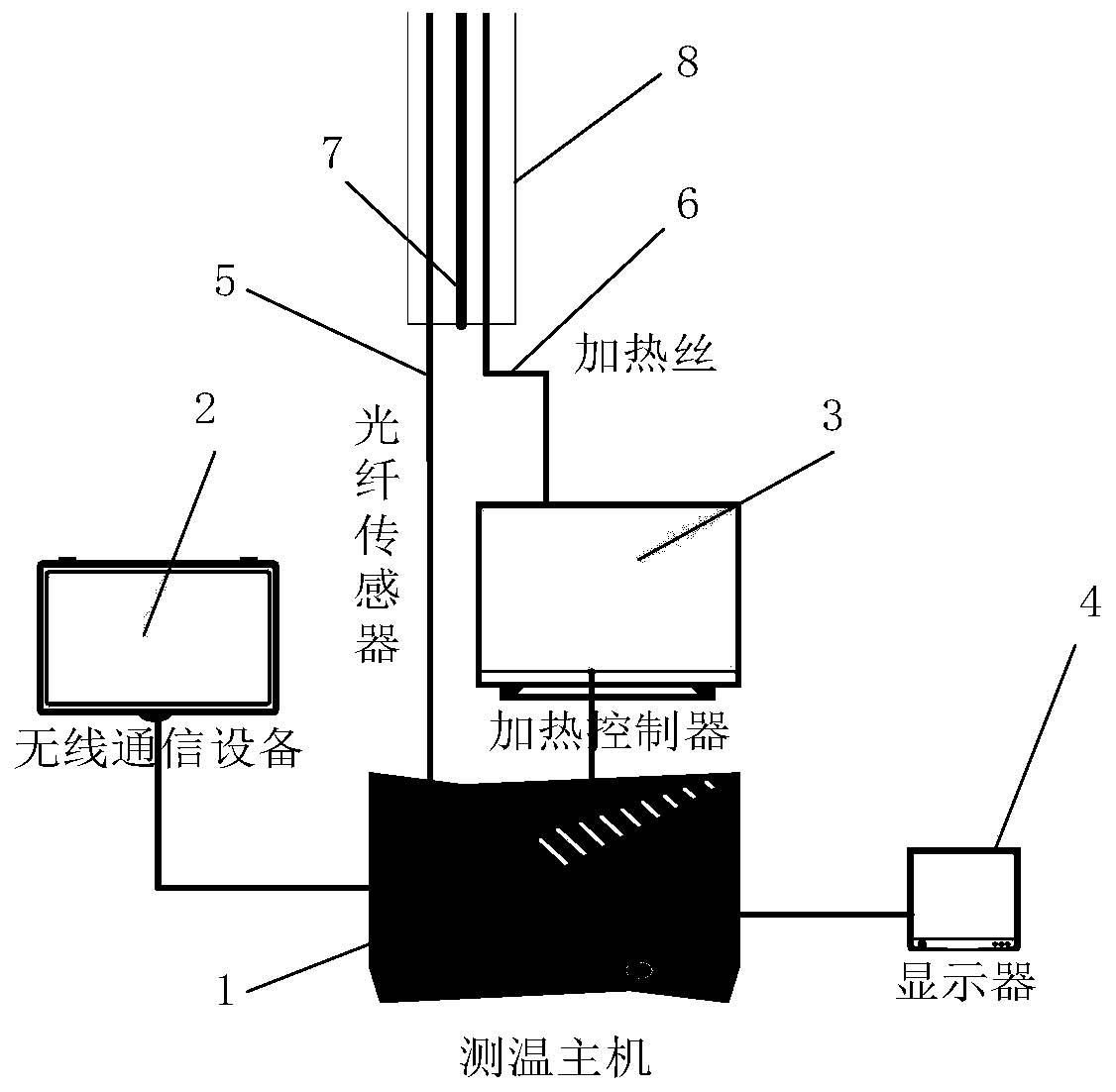

[0048] Such as figure 1 As shown, this example is used for a carbon fiber electric heating and deicing device for a medium-low speed maglev transportation power supply rail, including a distributed optical fiber temperature measurement component and a heating component. The distributed optical fiber temperature measurement component includes a temperature measurement host 1, an optical fiber sensor 5, a wireless communication Component 2, the temperature measurement host 1 is connected to the control center through the wireless communication component 2, and transmits temperature information in real time; the optical fiber sensor 5 adopts the spiral steel pipe armored temperature measurement optical cable commonly used in the market. The output end of the optical fiber sensor 5 is directly connected with the temperature measuring host 1 .

[0049] The temperature measurement host 1 is equipped with a display 4, the temperature measurement host is equipped with a windows operat...

Embodiment 2

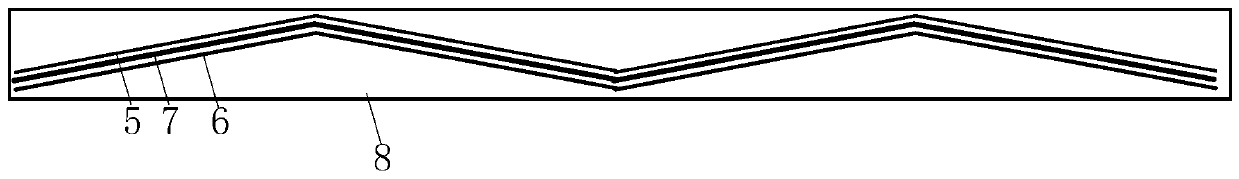

[0053] Such as Figure 4 , Figure 5 As shown, another form of power supply rail is characterized in that, on the basis of the existing Changsha medium and low-speed maglev train power supply rail, the lower part is provided with multiple card slots as required, and heating wire 6 and optical fiber sensor 5 are installed. The equipment is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com