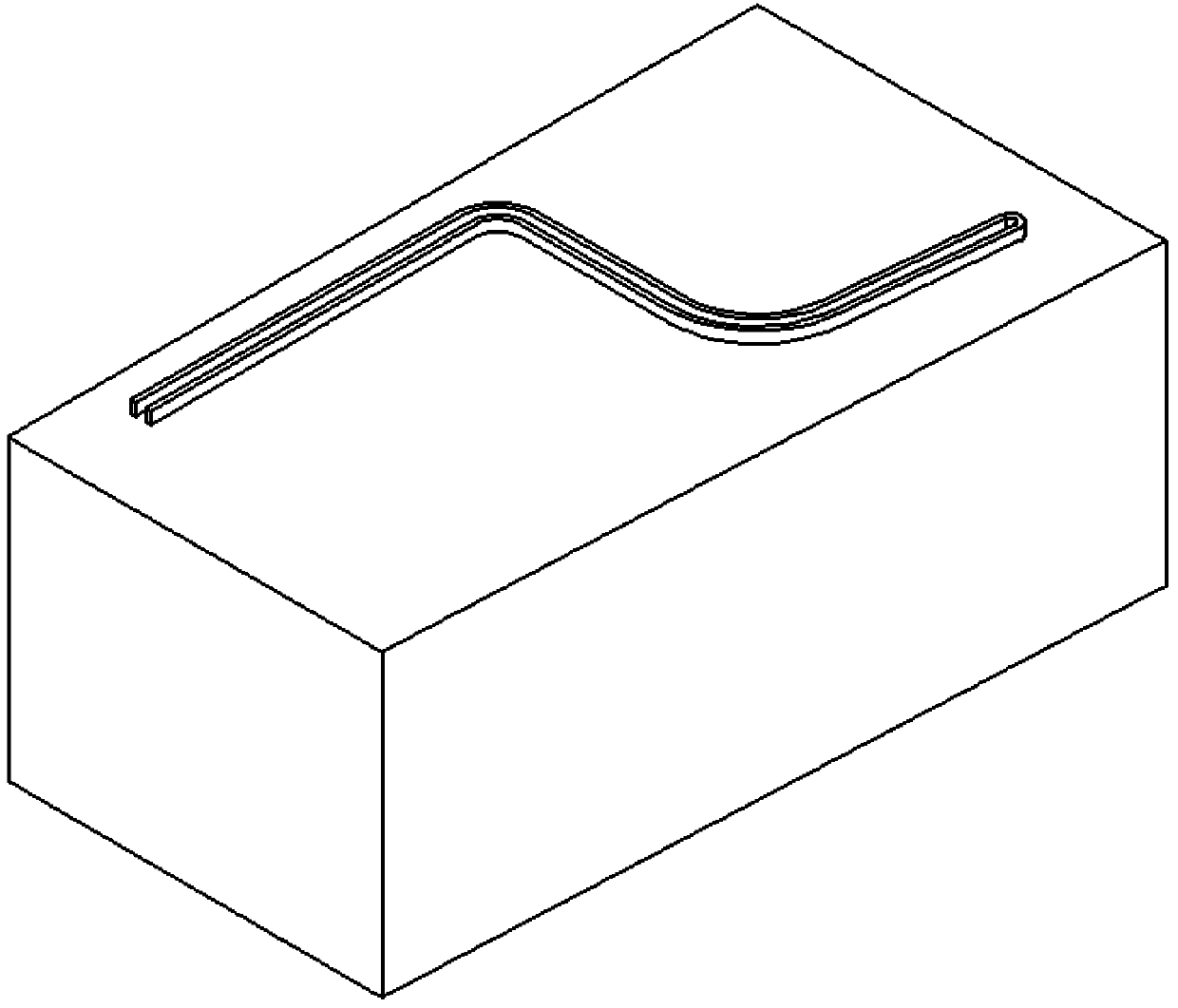

A Concrete Dam Distributed Temperature Measuring Optical Fiber Twin-strand "Z-shaped" Concrete Buried Construction Method

A technology of distributed optical fiber and temperature-measuring optical fiber, which is applied in thermometers, heat measurement, sea area engineering, etc., can solve the problems of less information in thermometers, strict working environment requirements, and complicated installation, so as to increase the amount of monitoring data and improve the survival of buried The effect of high efficiency and convenient data collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

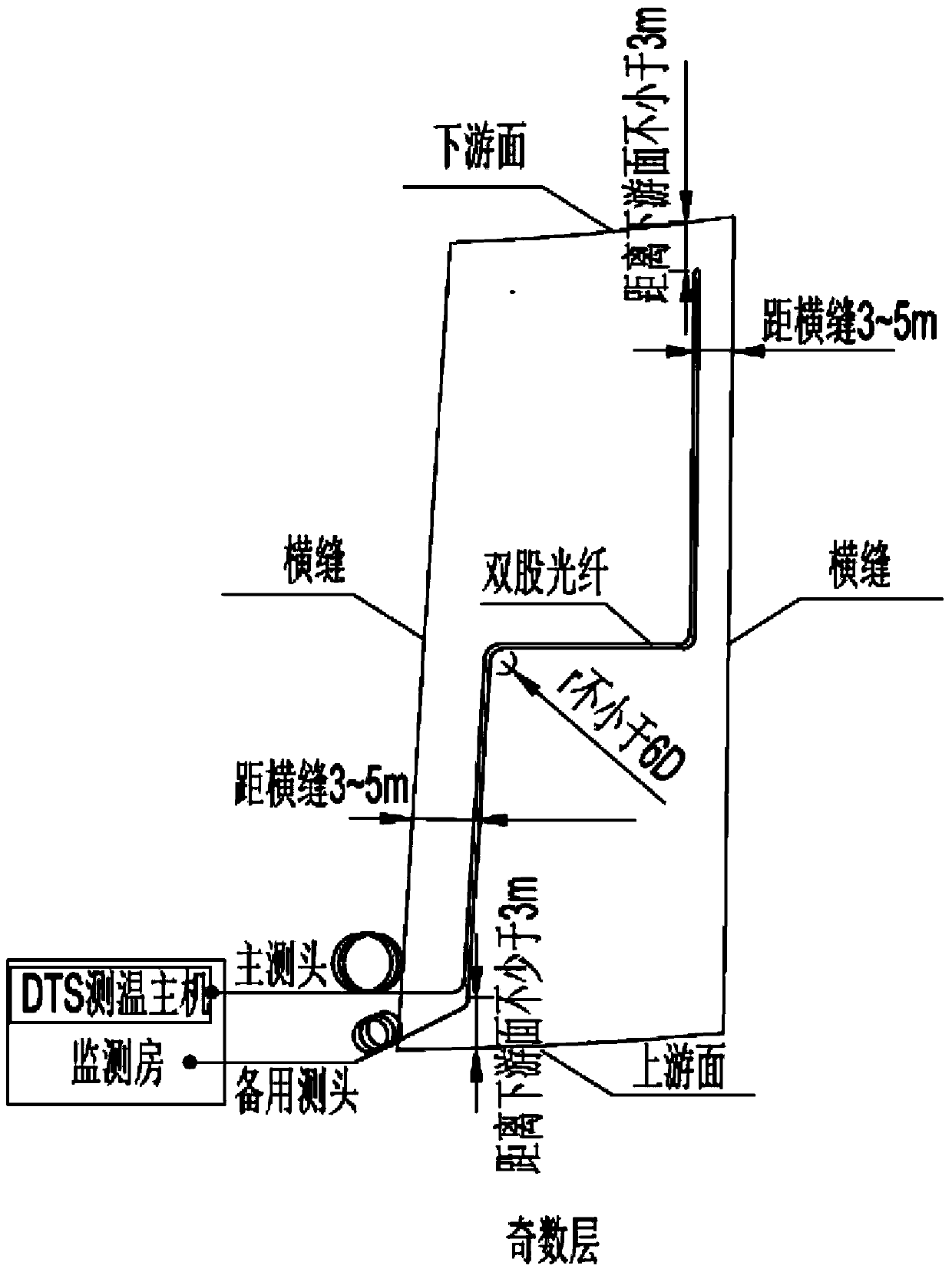

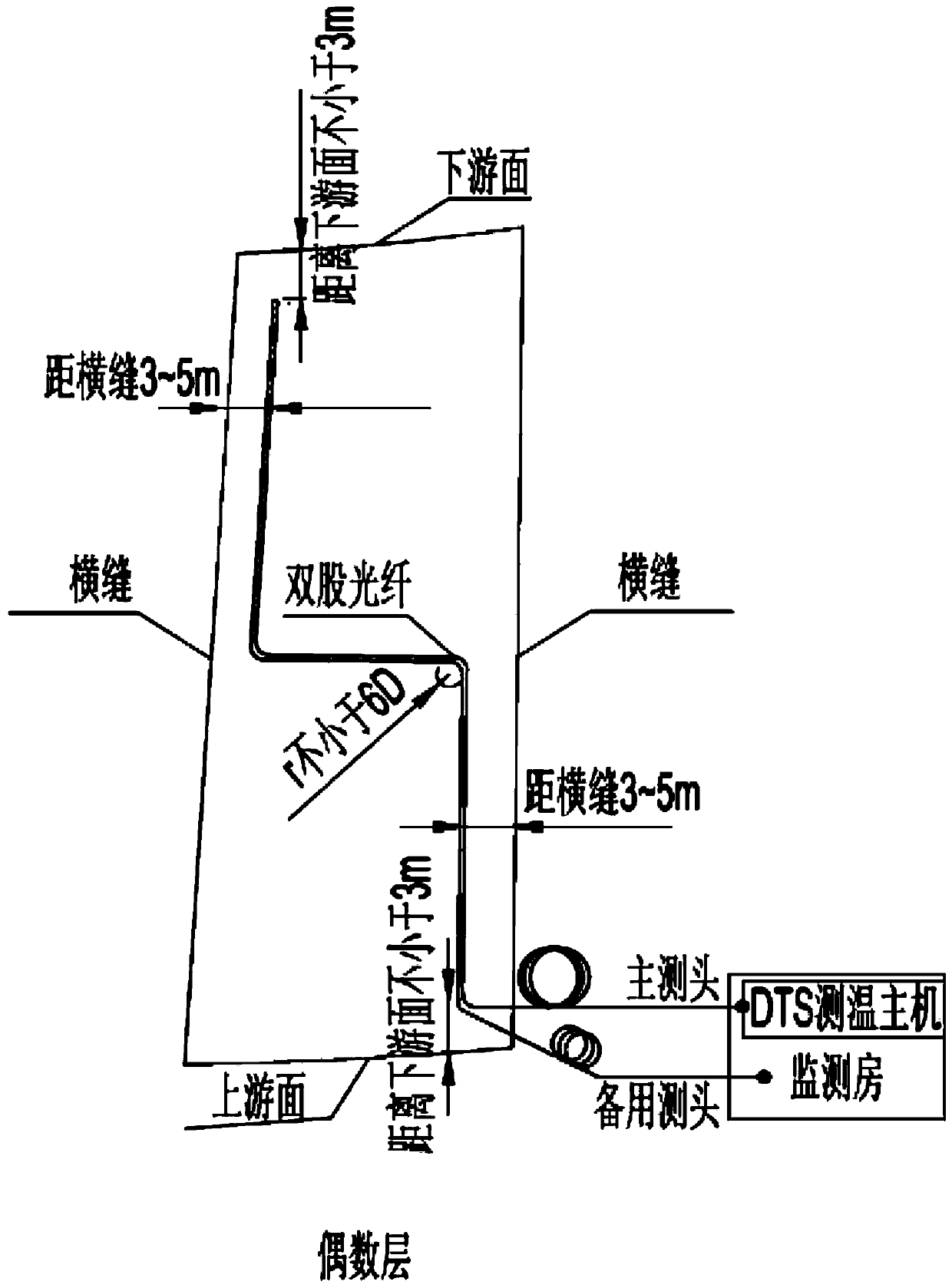

[0026] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0027] like Figure 1~Figure 6 As shown, the basic principles for the embedding of distributed temperature measurement optical fibers in concrete dams are as follows:

[0028] (1) The optical fiber embedding process does not affect the warehouse surface construction;

[0029] (2) During the construction process, avoid optical fiber vibration or rolling damage;

[0030] (3) Comply with the principle of laying optical fibers early after closing positions and vibrating.

[0031] The key control links of the distributed temperature measurement optical fiber embedding of concrete dams mainly include:

[0032] (1) The lead-in stage of the optical fiber embedding process increases with the height of the dam body.

[0033] (2) The stage of laying optical fibers through the warehouse.

[0034] (3) Odd and even layers alternately bury the lifting lead stage. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com