Device and method for controlling safe pressure of horizontal balance system of rolling mill

A technology of balancing system and safety pressure, applied in rolling mill control devices, fluid pressure actuating devices, fluid pressure actuating system components, etc., can solve problems such as lack of active protection measures, avoid equipment damage accidents, ensure normal operation, Achieving the effect of safe pressure protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

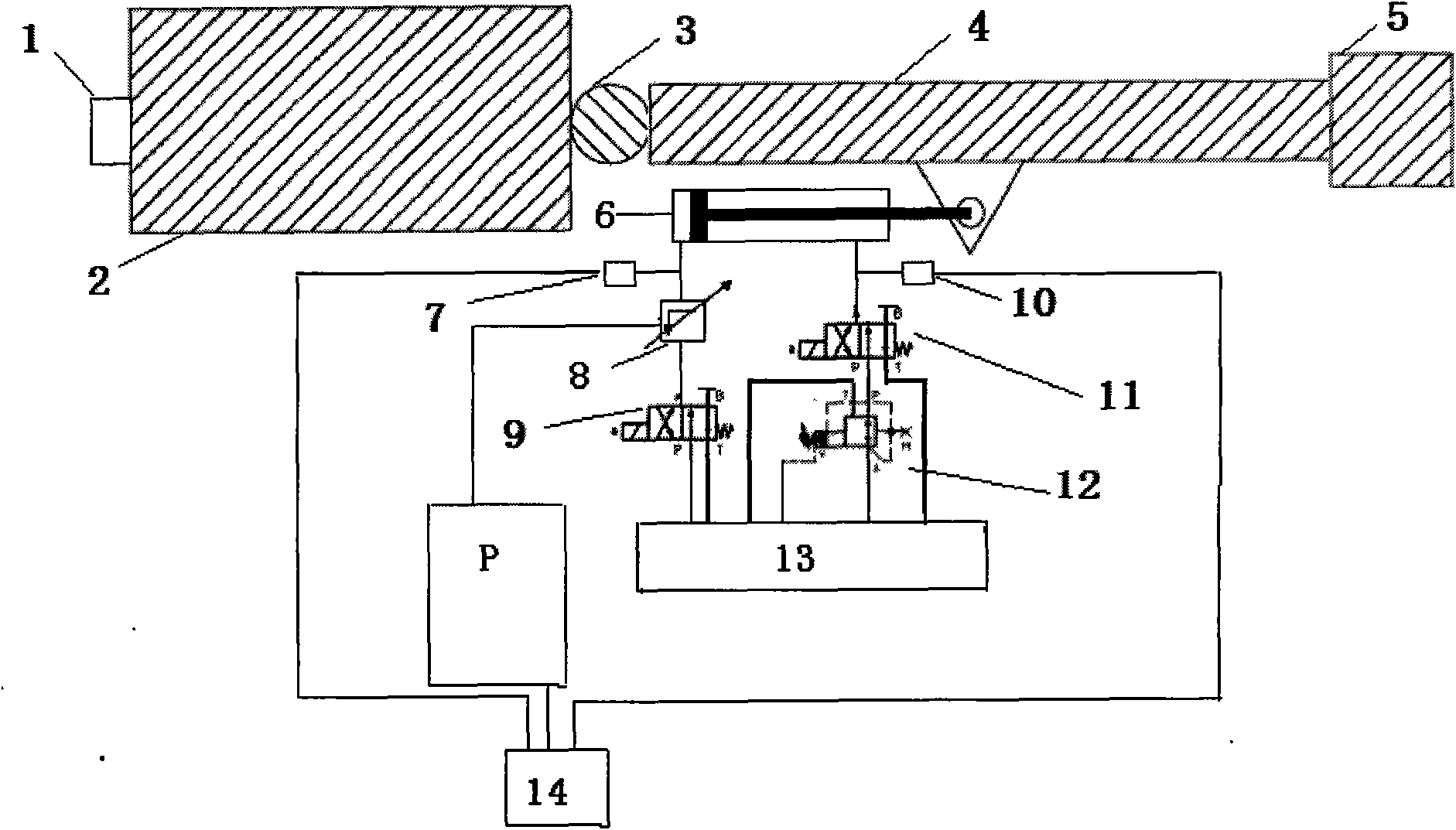

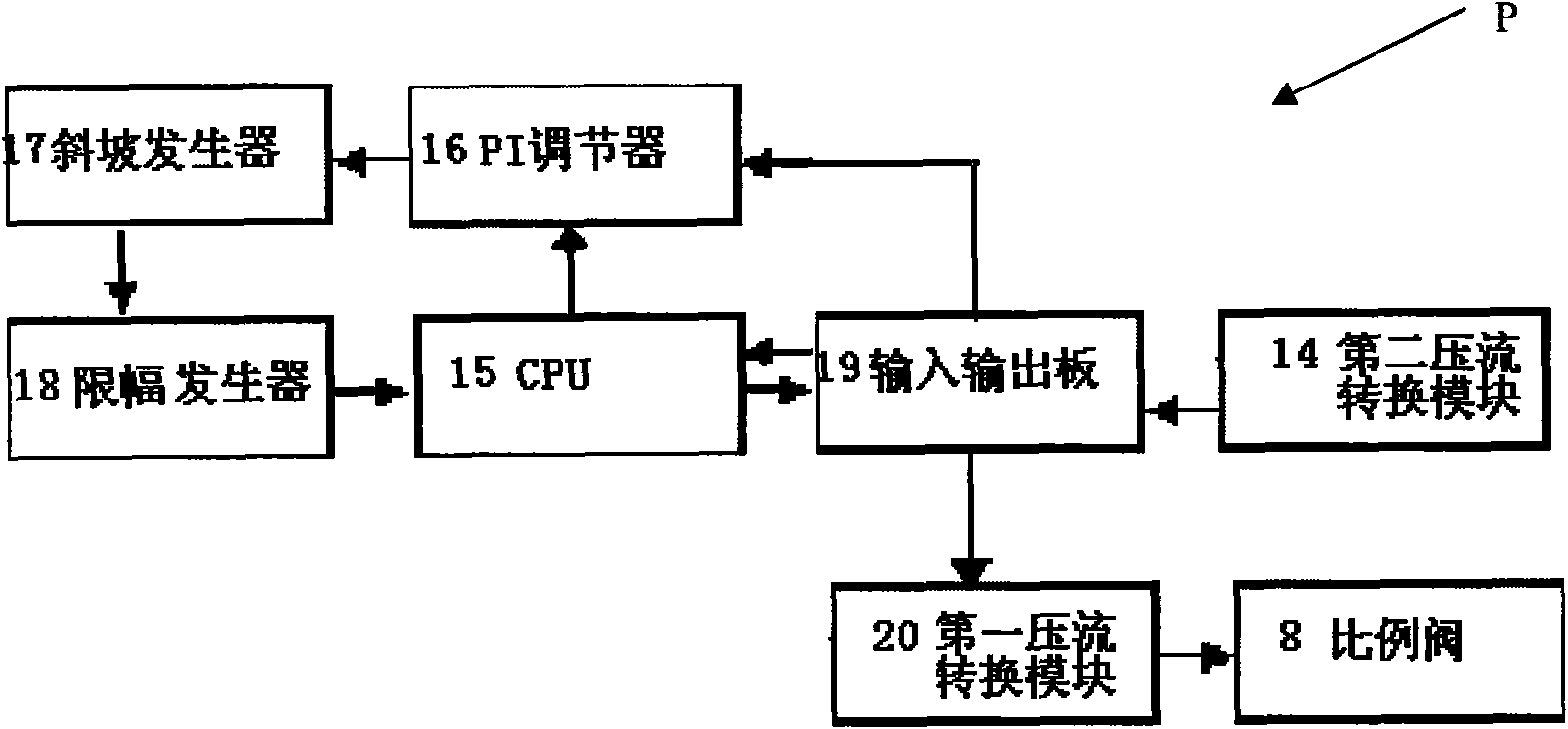

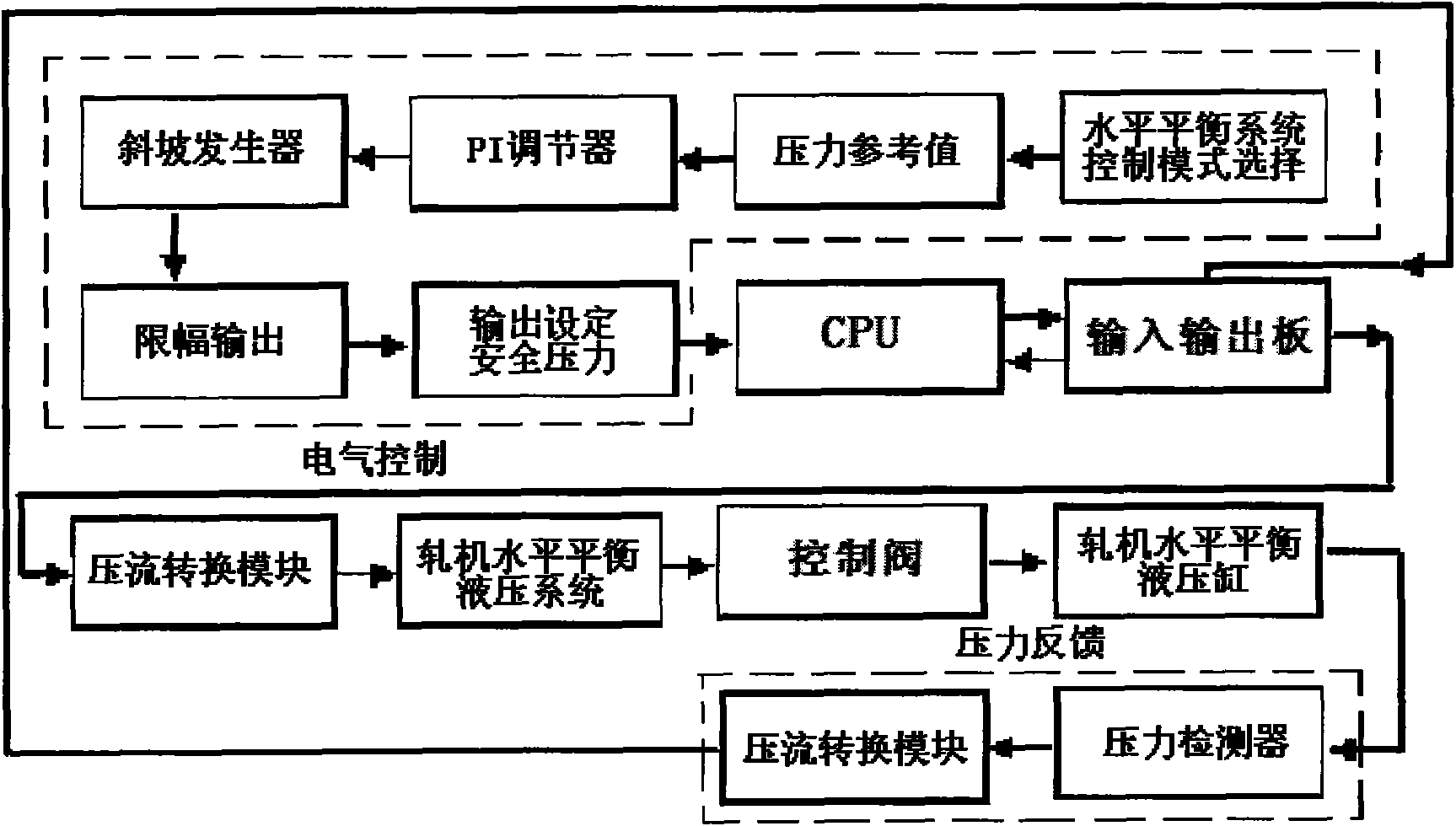

[0042] Such as figure 1 and figure 2 As shown, a preferred structure of the device for controlling the safety pressure of the horizontal balance system of a rolling mill in the present invention includes an electric control system P and a hydraulic actuator system connected to it through a data line.

[0043] The electrical control system P includes:

[0044] CPU15 calculates the pressure reference value according to the control mode of the rolling mill;

[0045] The PI regulator 16 is connected to the CPU 15, receives the pressure reference value sent by the CPU, and performs proportional-integral adjustment on the pressure reference value to realize pressure closed-loop control;

[0046] The slope generator 17 is connected to the PI regulator 16, and performs corresponding compensation control for the current peak mode according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com