A circular rotating coke tank balance detection device and method

A detection device and circular rotation technology, which is applied in the direction of measuring device, static/dynamic balance test, machine/structural component test, etc., can solve the problem of deviation, slipping out, damage to traversing trolley and other equipment, and affect production security issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings of the embodiments.

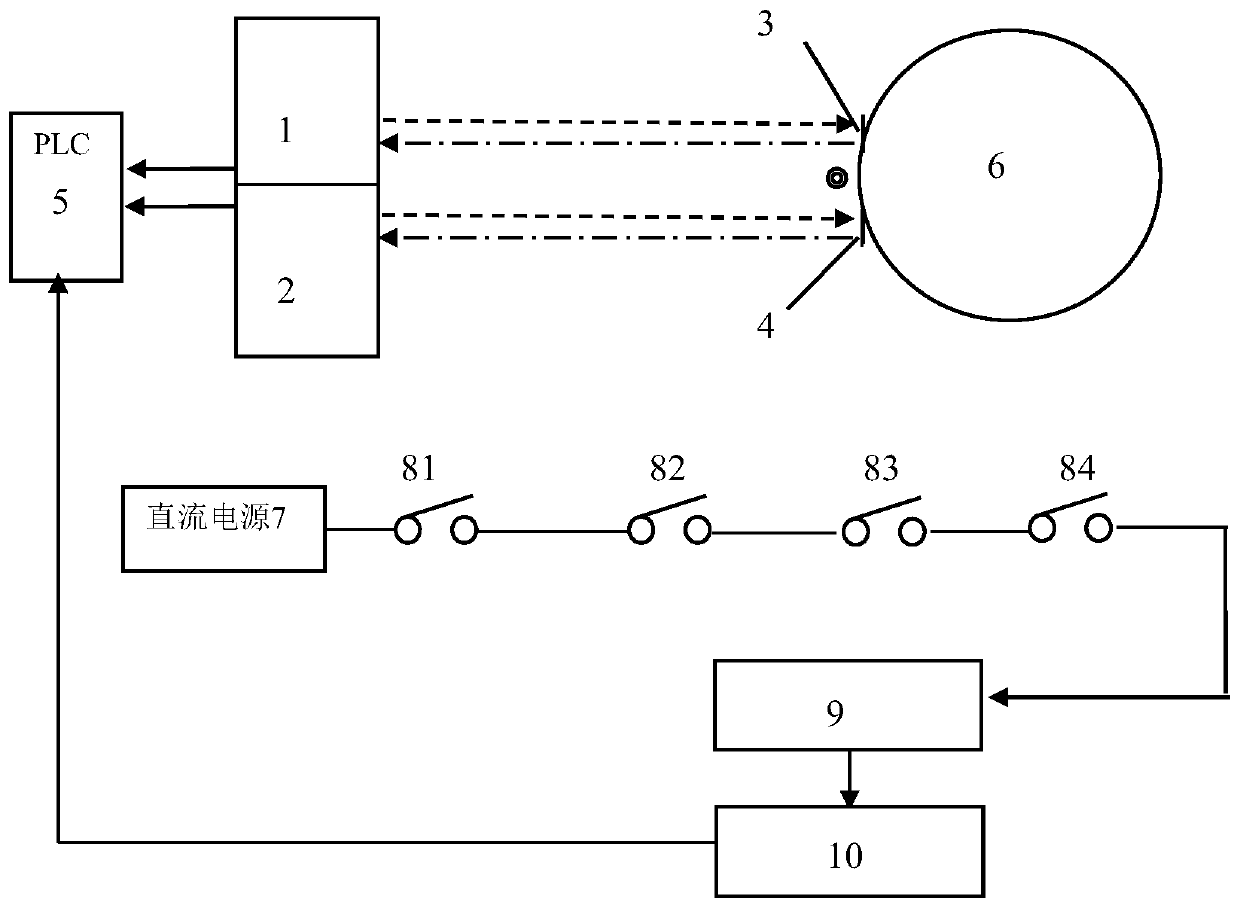

[0026] The structure of the circular rotating coke tank balance detection device of the present invention can be found in figure 1 , which consists of a first infrared detection device 1, a second infrared detection device 2, a first infrared reflector 3, a second infrared reflector 4, a PLC controller 5 and a mechanical pendulum limiter.

[0027] The first infrared detection device 1 and the second infrared detection device 2 are installed on one side of the rotating coke tank 6 in parallel, the first infrared detection device 1 and the second infrared detection device 2 each consist of a group of L-GAGE LT3 sensors, A group of short electrical pulses in each group of sensors drives a semiconductor laser diode to emit laser pulses, and two groups of laser pulses pass through the collimating lens to form two g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com