Intelligent modular electric shock proof angle grinder

An intelligent module, anti-electric shock technology, used in grinding machines, measuring electricity, electrical components, etc., can solve problems such as electric shock accidents, personal injury equipment, fire, etc., to avoid equipment damage and avoid personal injury.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

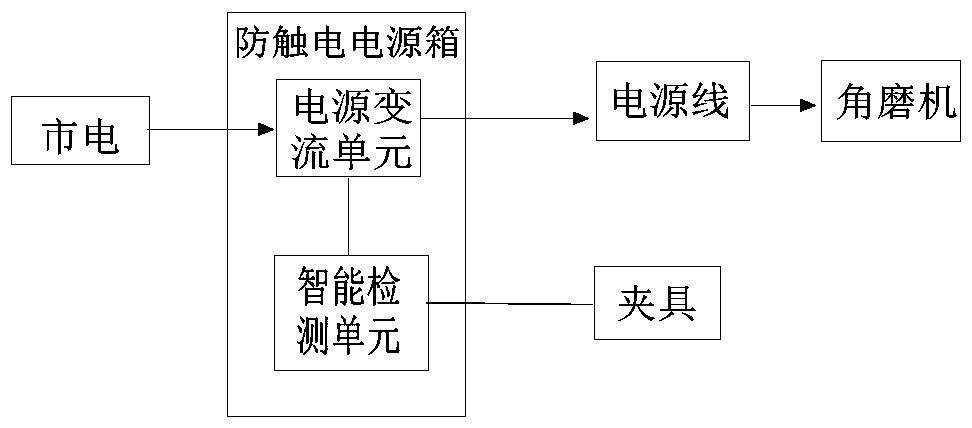

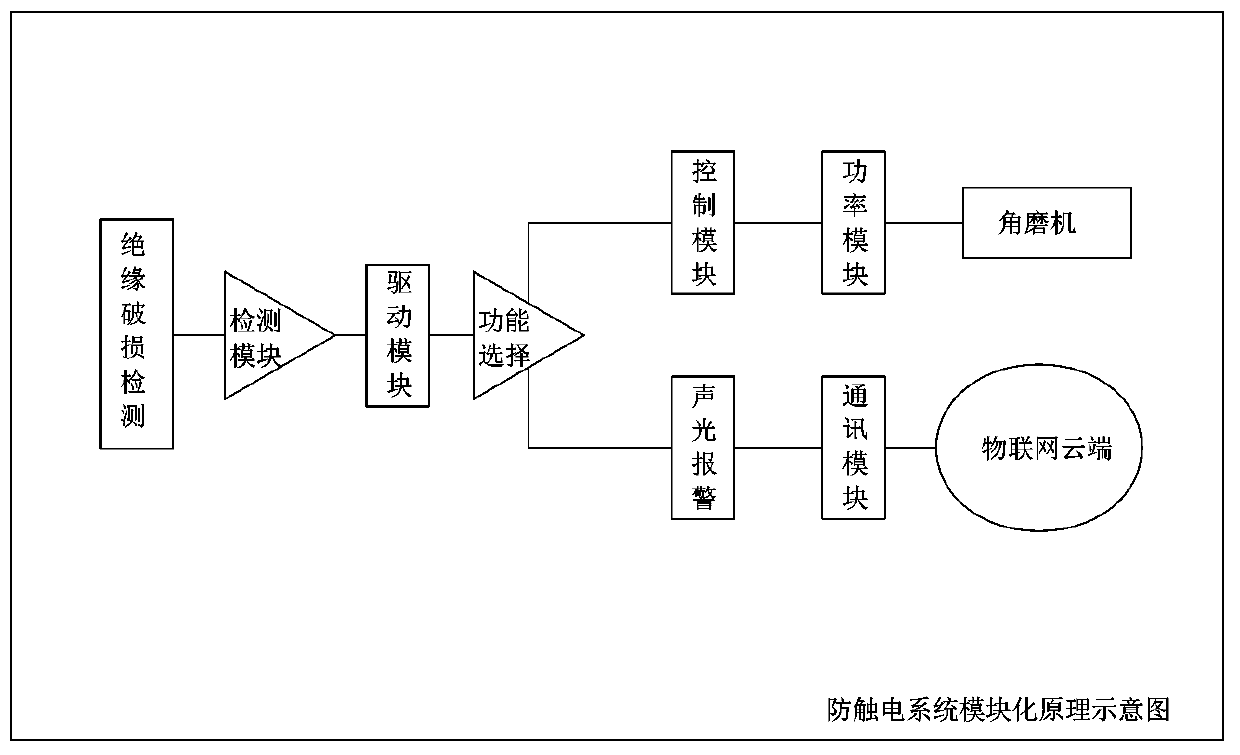

[0017] Such as figure 1 shown to figure 2 An intelligent modular anti-shock angle grinder is shown, which is characterized in that: an anti-shock power box and a power cord with a shielding layer are used, and the angle grinder is connected to the anti-shock power box through the power cord with a shielding layer; The anti-shock power supply box includes a power conversion unit and an intelligent detection unit; the power conversion unit is connected to the mains to output DC to the angle grinder, and the intelligent detection unit detects whether the power line and the angle grinder are leaking.

[0018] Further, the power conversion unit includes a leakage protector, a contactor, an isolated power supply module and a conversion module, the contactor is connected to the mains through the leakage protector, and the other end of the contactor is connected to the isolated power supply module, and the isolated power supply The module is connected with the converter module, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com