Positive- and negative-direction blowing-in and-out stilling -eliminating fan

A technology of air supply and exhaust, high-speed fan, applied in mechanical equipment, machine/engine, liquid fuel engine, etc., can solve problems such as surge, drop, equipment damage, etc., and achieve the effect of preventing equipment damage accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

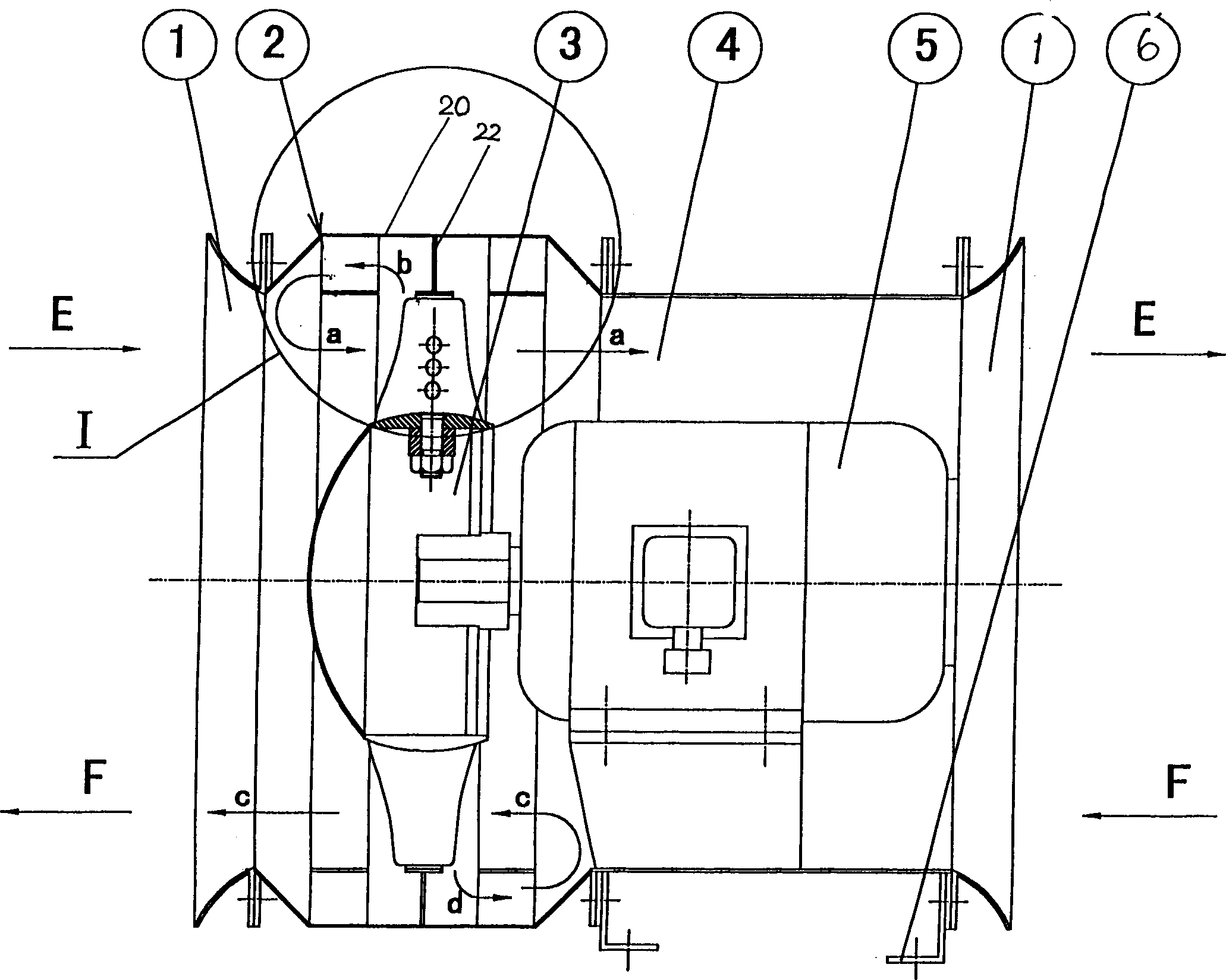

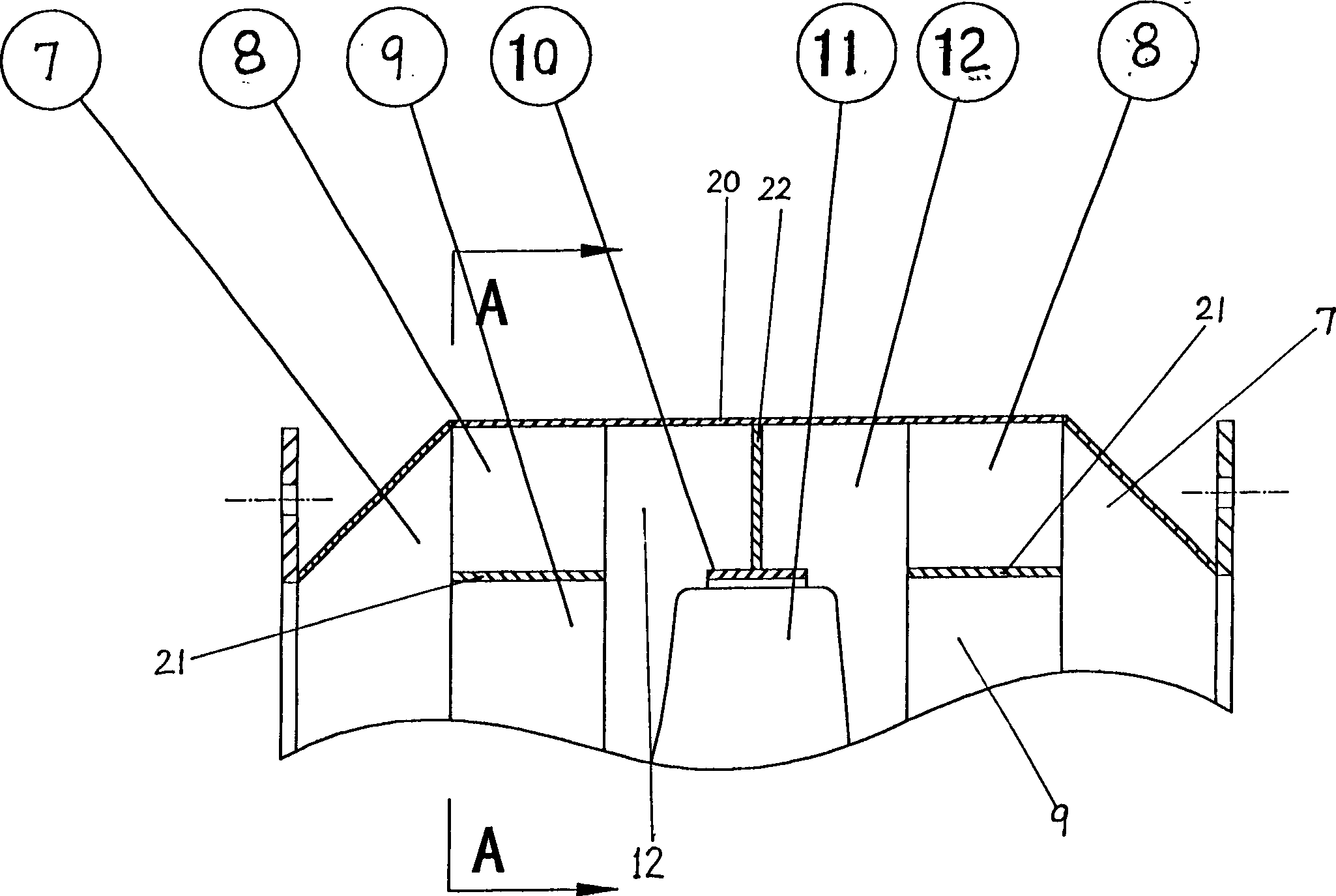

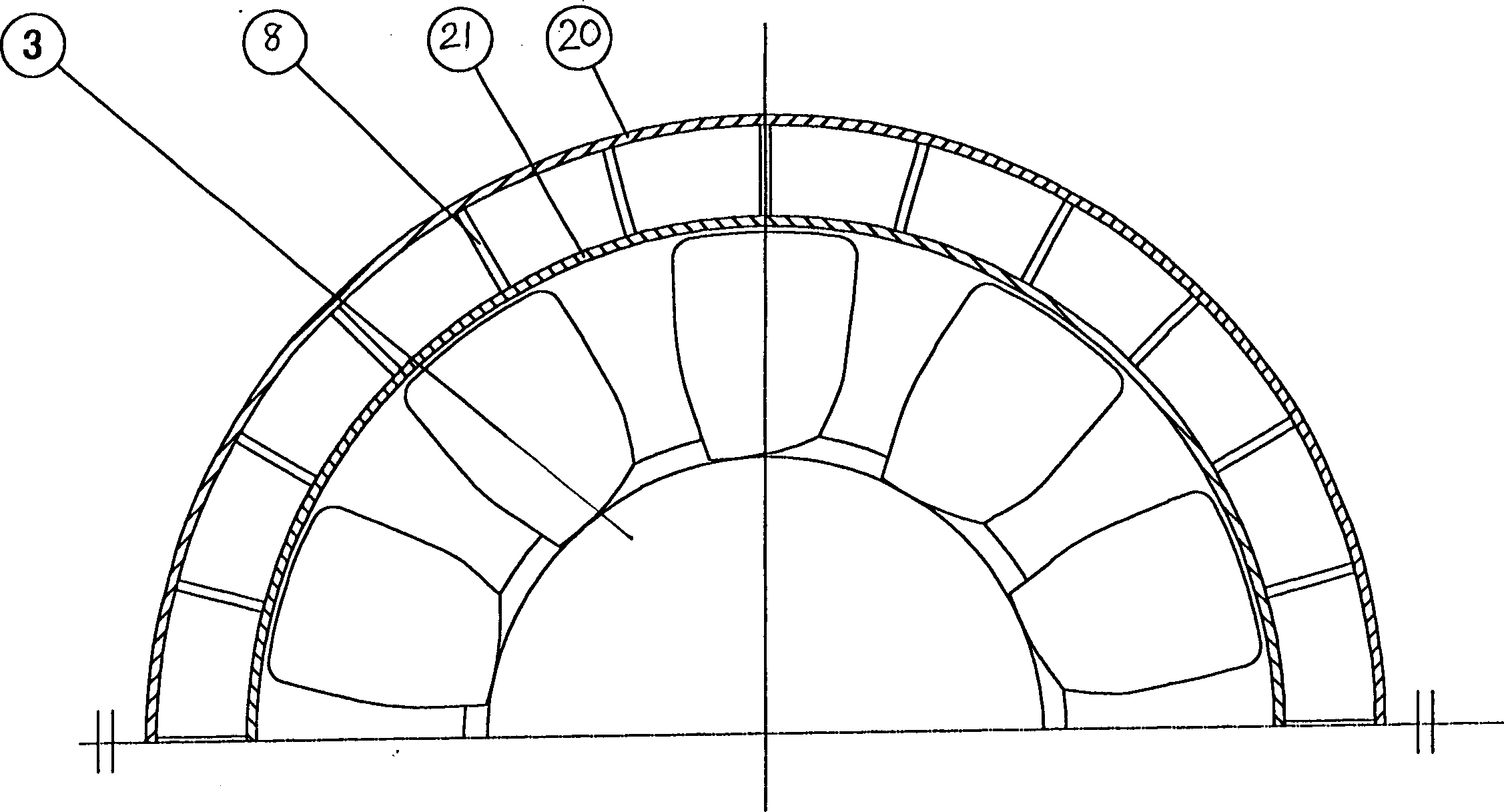

[0010] like figure 1 , figure 2 and image 3 As shown, the structure of the forward and reverse air supply and exhaust fan of the present invention includes a base 6 at the bottom of the base, a motor 5 inside the casing 4, an impeller 3 fixed on the motor shaft head and its The blade 11, the current collector 1 located at the end of the casing 4, its main feature is that a reflux device 2 protruding from the casing is provided outside the circumference of the impeller part, the middle section is a hollow cylinder; the two sides of the middle section are Hollow conical cone expansion tube 7; its inner end is fixedly connected with the inner end of the casing 4, and the present embodiment is connected by bolts through a flange; its outer end is fixedly connected with the inner end of the left collector 1, In this embodiment, the flanges are connected by bolts; the maximum outer diameter is greater than the outer diameter of the casing 4; In this way, the casing 4, the curre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com