Single-bucket serial-bucket charging method applied to bell-free blast furnaces

A charging method and blast furnace technology, which are applied in the field of single-tank string-tank charging, can solve the problems of the impact of blast furnace pig iron output, the pulling of materials from hoists, and production interruption, so as to increase flexibility and practicability, eliminate production interruption problems, and improve economy. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

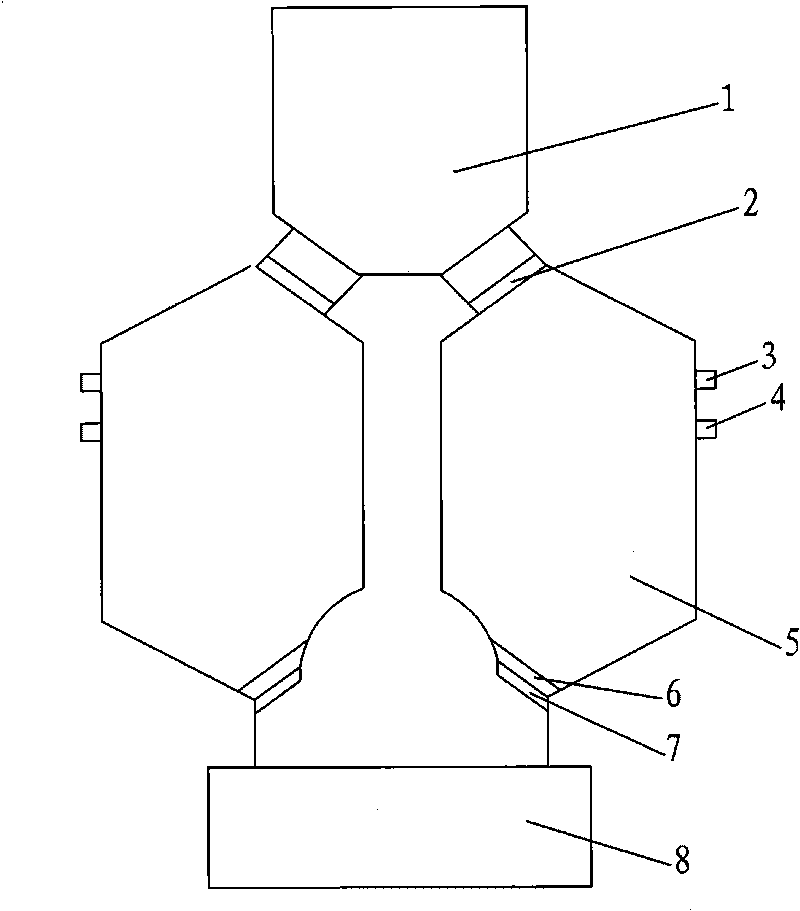

[0025] A single-tank cascading feeding method applied to a bellless blast furnace, as shown in the attached figure, when one of the two batch tanks of the bellless blast furnace fails, the faulty batch tank is deactivated and emptied For the material, keep the receiving hopper fixedly connected to another non-faulty material tank at this time, and use the receiving hopper and the feeding space above the sealing valve plate on the non-faulty material tank together as the feeding tank 1, and the non-faulty material tank The material tank is used as the lower material tank 5 to form a single tank string tank feeding situation in which the upper and lower material tanks 1 and 5 are connected in series to ensure uninterrupted production of the blast furnace.

[0026] The operation steps of charging into the blast furnace through the upper and lower tanks connected in series are as follows:

[0027] (1), first, the lower material tank 5 is ready to discharge and empty, the upper sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com