Method and device for solving problem of abnormal empty value of material in charging bucket

A material tank and material empty technology, which is applied in the field of solving the abnormal empty value of the material tank in the blast furnace feeding system, and can solve the problems such as the abnormal empty value of the material tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] It is worth noting that the orientation words such as "up" and "down" involved in this article are all determined relative to the perspective of the drawings, and are only for the convenience of description, and cannot be understood as limitations on the technical solution.

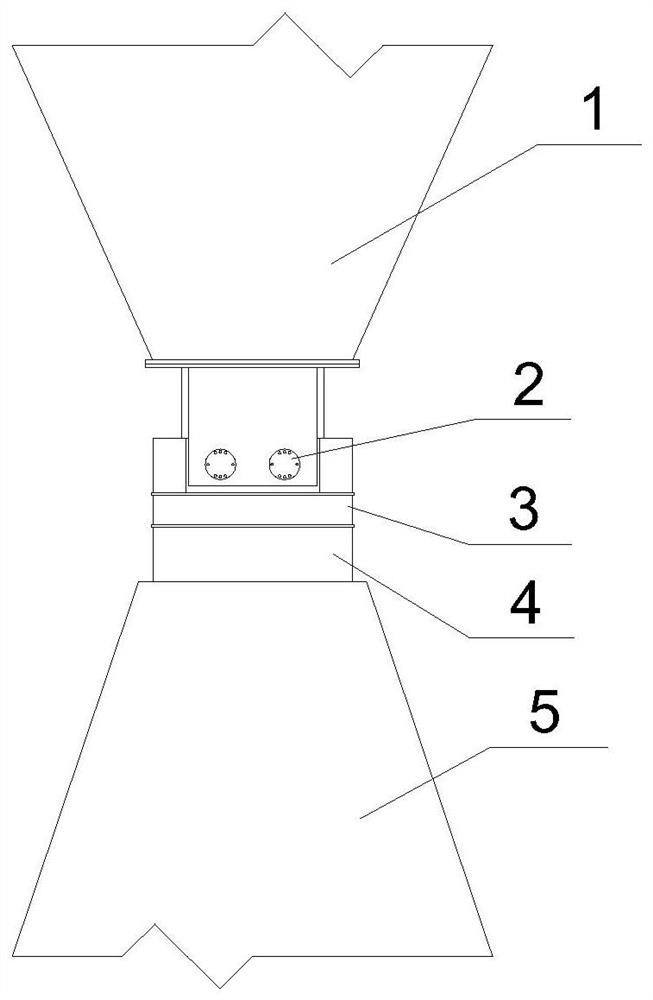

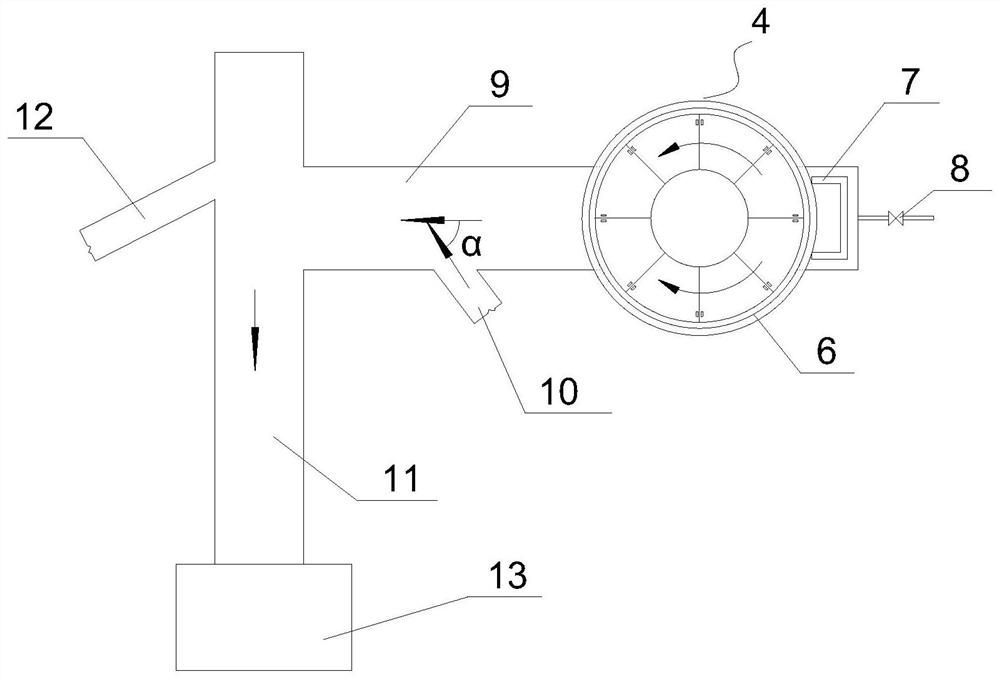

[0023] Such as figure 1 with figure 2 As shown, a method to solve the abnormal empty value of the material tank. First, the existing material feeding system includes a material receiving tank 1, a material feeding gate 2, a dust collector 4 and a weighing tank 5 connected sequentially from top to bottom. , There is also a soft connection 3 between the feeding gate 2 and the dust collector 4 to facilitate installation and disassembly, and the application of different sizes. The method includes the following steps: at the outer edge of the dust removal ring 6 in the dust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com