Full-automatic feeding and discharging machining workstation for ultra-precision cone body

An ultra-precision, loading and unloading technology, used in metal processing and other directions, can solve the problems of laborious processing, increasing labor costs, and increased equipment prices, so as to save equipment costs and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

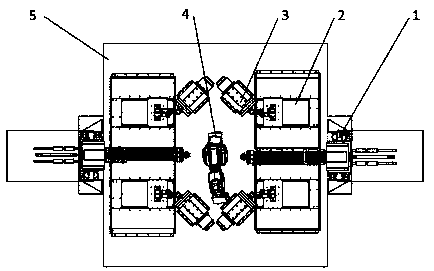

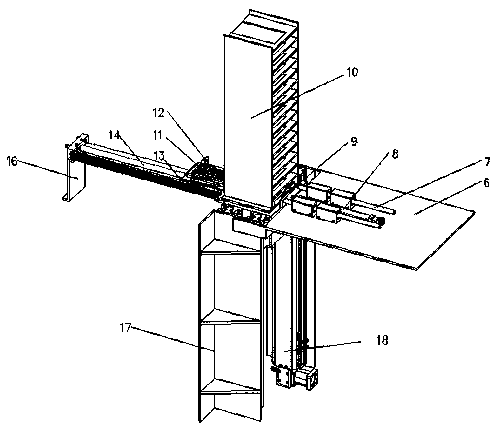

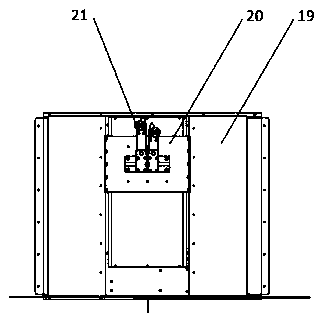

[0019] Such as Figure 1-2 As shown, a kind of ultra-precision vertebral body automatic loading and unloading processing workstation of the present invention includes two groups of automatic feeding tray systems 1 symmetrically arranged on the machine platform assembly 5, super Precision tool holder system 2, ultra-precision spindle 3 coordinated with the ultra-precision tool holder system, and robot handling system 4 set in the middle of the machine assembly;

[0020] The automatic feeding tray system includes a tray 11 for placing vertebral body parts 15, a jacking module 18, a corner seat 17, and a material storehouse 10. The material storehouse 10 is a stacked structure, and each layer has a A pallet 11 is provided with a retractable grabbing structure on the tooling pallet 6 on one side of the material warehouse 10, and the grabbing structure includes a pallet gripper 9, a cylinder 8 for controlling the movement of the tray gripper 9, and a linear guide rail 7. The cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com